Have you ever thought about how much easier your project could be with the right mini excavator attachments? I always check the job, the site, and my machine before I pick an attachment. The right attachments can help you work up to 50% faster. They can also make your work safer and save money. Mini excavator attachments like the Mini Excavator Breaker Hammer, Mini Excavator Hydraulic Thumb, Metal Wide Backhoe Rake, Excavator quick-change connector, or Excavator rotary drilling rig can change how you do a job. I always remind myself to pick attachments that fit my needs and my excavator. Mini excavators can do more when I use the right tools for the job.

Project Requirements

Define Tasks

When I start a new project, I always make a list of the main tasks I need to finish. This helps me figure out which excavator attachments will work best. Some jobs need digging, while others need lifting or breaking up hard ground. I ask myself questions like, “Will I need to move rocks or logs?” or “Do I have to dig deep holes for fence posts?”

Here are some common tasks I handle with my mini excavator:

Breaking up old concrete or asphalt with a hydraulic breaker

Digging holes for trees or posts using an auger

Moving logs, rocks, or scrap metal with a grapple

Leveling soil for a new lawn or garden with a grading bucket

Compacting soil for a strong foundation

Switching between attachments quickly with a quick coupler

I know that using the right attachment for each task can save me time and effort. One machine can do many earthmoving jobs if I pick the right tools. This means I do not need to rent extra equipment, which saves money and keeps my project simple.

Set Goals

Before I choose any attachment, I set clear goals for my project. I decide how fast I want to finish, how much I want to spend, and what quality I expect. I look at my excavator’s power, lifting ability, and reach. I also check if I need special features like safety cameras or comfortable controls.

Here is a table that shows how setting goals can help me pick the right attachment:

Goal Type | What I Check | How It Helps Me |

|---|---|---|

Speed | Attachment change time, digging rate | Finish tasks faster |

Cost | Fuel use, maintenance needs | Save money on each job |

Safety | Safety features, operator comfort | Keep everyone safe and focused |

Quality | Precision, digging depth | Get better results for my clients |

When I match my goals with the right attachments, I notice my team works faster and takes fewer breaks. We finish jobs up to 15% quicker. This makes my clients happy and helps my business grow.

Mini Excavator Attachments Types

When I get ready for a new job, I look at all the different excavator attachments. Picking the right tool makes my mini excavator stronger and more useful. I want to show you the main attachments I use the most.

Buckets

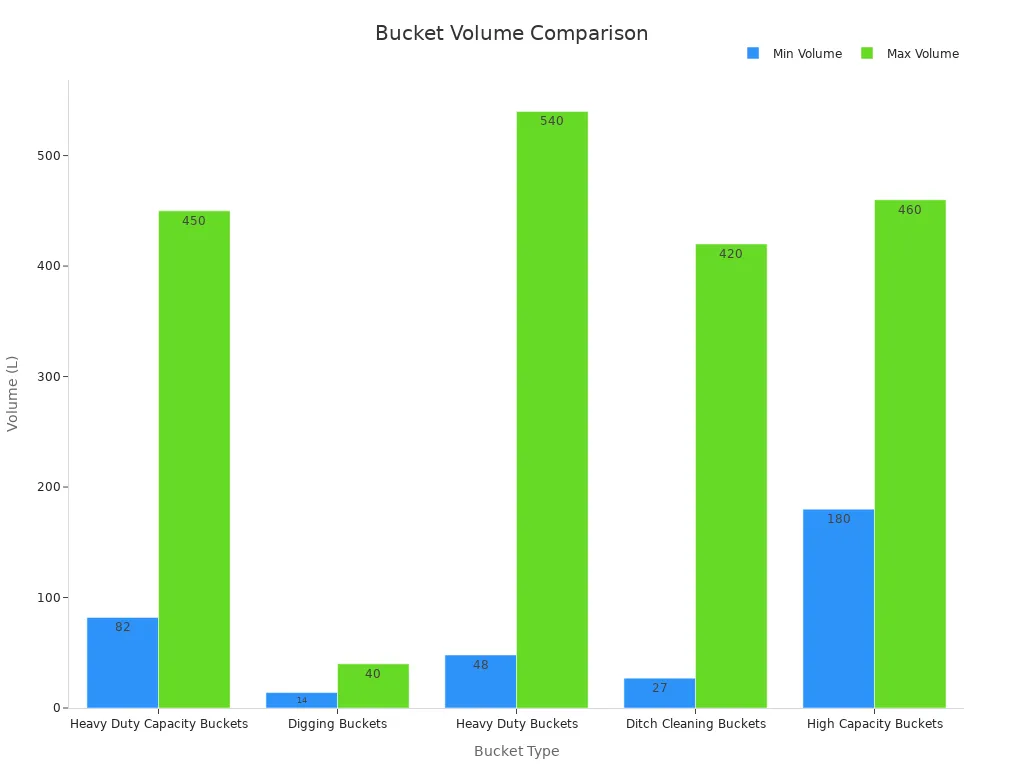

Buckets do a lot of work on earthmoving jobs. I use them to dig, grade, and move dirt or gravel. DeepKron has strong buckets, slant buckets, and the 1000 Mud Bucket. These buckets fit most machines and can handle hard jobs. Here is a table that shows some common bucket types and what they do:

Bucket Type | Width (mm/in) | Volume (L/ft³) | Notes on Application |

|---|---|---|---|

Heavy Duty Capacity Buckets | 305-914 (12-36) | 82-450 (2.9-15.9) | Max digging force and volume |

Rock Buckets | 610-762 (24-30) | N/A | For loading abrasive rock |

Grading Buckets | 1000-1800 (39-71) | N/A | Grading, loading, backfilling |

Digging Buckets | 230-370 (9-15) | 14-40 (0.5-1.4) | Soft to moderate ground |

Ditch Cleaning Buckets | 700-1800 (28-71) | 27-420 (1-14.8) | Cleaning ditches, sloping, grading |

I always pick a bucket size that matches my job. This helps me dig faster and move more dirt with less work.

Hydraulic Breakers

If I need to break concrete or rocks, I use a hydraulic breaker. DeepKron’s Breaker Hammer is one I like a lot. It fits most mini excavators and hits very hard. New models are safer and more comfortable. They have noise control, auto shut-off, and strong covers. These features help keep me safe and make my job easier. I work 36% faster and feel 31% safer with these new attachments.

Grapples

Grapples help me move logs, rocks, and scrap metal. DeepKron’s Mini Loader Log Grabber and Material Handling Tool are good for waste and recycling. Grapples are 11% of all mini excavator attachments. They are great for handling wood, working in forests, and cleaning up cities. I use them when I need to grab things tight and move them fast.

Attachment Type | Market Share (%) | Key Application Areas (%) |

|---|---|---|

Grapples | 11 | Waste (18%), Recycling (18%), Timber (18%), Forestry (9%) |

Augers

I use augers to drill holes or test soil. DeepKron’s Excavator Rotary Drilling Rig gives me the power and control I need. Augers work in all kinds of ground and can drill deep holes for posts or building bases. Hydraulic augers save me time and mean I need fewer workers.

Thumbs and Rippers

Thumbs and rippers make my mini excavator do more jobs. DeepKron’s Hydraulic Thumb helps me grab odd shapes, and their Scarifier breaks up hard dirt. These tools make my machine more useful. I can go from digging to breaking or landscaping without changing machines. This saves money and keeps my work going.

Specialized Attachments

Sometimes, I need special tools. DeepKron’s Quick-Change Connector and Four-in-One Tool let me switch attachments fast. Their Metal Wide Backhoe Rake is great for clearing land. Special attachments like these help me finish jobs faster and do better work. I can get up to 50% more done with the right tool.

Tip: I always make sure my attachments fit my mini excavator and match the job. This keeps my work safe and helps me do a good job.

I think knowing about excavator attachments and picking the right ones makes every job easier. With DeepKron’s tools, I can handle almost any problem at work.

Matching Excavator Attachments

Material and Site

When I start a new project, I always look at the ground and the materials I need to move. Some sites have soft soil, while others have hard clay or rocks. I know that the type of material changes how my excavator attachments work. For example, when I use buckets in loose sand, I can move more dirt with each scoop. If I work in dense clay or rocky ground, I pick a narrower bucket. This helps me dig deeper and break through tough spots.

Here are some things I notice about material and site conditions:

Bucket payload stays about the same, even if the material gets heavier.

When the ground is dense, my machine uses more hydraulic power.

Digging in rocky soil makes the bucket work harder.

Most of the power goes into digging, not lifting.

I also pay attention to the size of the site. In tight spaces, I use smaller buckets and attachments. On open ground, I switch to wider buckets to finish faster. I learned that matching the right bucket to the material and site helps me save time and keeps my machine running smoothly. If I need to do trench excavation or drainage work, I always check the soil first and pick the best attachment for the job.

Tip: I always match my attachment size and type to the ground and space I have. This keeps my work safe and efficient.

Job Complexity

Some jobs are simple, like moving dirt from one place to another. Others are much harder, like digging deep trenches or breaking up old concrete. I think about how complex the job is before I choose my excavator attachments. If I need to do more than one thing, I pick attachments that can handle different tasks.

For example, I once had to dig a long trench and then clear away heavy debris. I used a hydraulic breaker to break up the concrete, then switched to a grapple to move the broken pieces. This made the job go much faster. I also remember a project where I had to dig a 100-meter trench in just a few hours. By using the right attachments, I finished ahead of schedule and saved money.

I know that the harder the job, the more important it is to pick strong and reliable attachments. When I use DeepKron’s attachments, I feel confident that I can handle tough jobs without slowing down.

Versatility Needs

I like to use attachments that can do more than one thing. This makes my mini excavator much more useful. Sometimes, I need to switch from digging to lifting or from grading to clearing brush. Versatile attachments help me do all these jobs without changing machines.

I have seen how attachments like flail mowers and hydraulic rock grabs make my work easier. With a flail mower, I can clear weeds and grass on a construction site. With a hydraulic rock grab, I can pick up big rocks or logs. I remember a time when I had to clear 500 tons of debris in one shift. Using the right attachments, I finished the job quickly and saved 30% on costs.

Here are some reasons why I choose versatile attachments:

I can do more jobs with one machine.

I save time by switching attachments quickly.

I finish projects faster and keep my clients happy.

Note: Versatile excavator attachments help me handle complex tasks in construction, landscaping, and even agriculture. I always look for attachments that fit many jobs and make my work easier.

Compatibility

When I pick excavator attachments, I always check if they fit my machine. Getting the right match keeps my work safe and helps me get the best results. I learned that not all attachments fit every mini excavator. Manufacturer specs like hydraulic flow, weight limits, and coupler types matter a lot. If I skip this step, I might end up with tools that don’t work well or even damage my equipment. DeepKron makes this easier for me because their universal design fits most machines, so I spend less time worrying about excavator attachment compatibility.

Machine Size

I always start by looking at my mini excavator’s size. Each machine falls into a size class, like under 1 ton, 1 to 2 tons, 3 to 5 tons, or 6 to 10 tons. Smaller machines work best in tight spaces and lighter jobs. Bigger ones handle heavy lifting and tough digging. I match the size and weight of my attachments to my excavator’s lifting power. If I use attachments that are too heavy, my machine slows down and can even get damaged. If the attachments are too light, I waste time and don’t get the job done right.

Attachments that are too big strain the hydraulics.

Small attachments may not move enough material.

Each size class has its own best uses and limits.

I always check the specs and use performance charts to see what works best for my machine.

Hydraulic Flow

Hydraulic flow is like the heartbeat of my mini excavator. It powers my attachments and keeps them running strong. I check the hydraulic flow and pressure numbers in my machine’s manual before I buy new excavator attachments. If the attachment needs more flow than my machine gives, it won’t work well. If it needs less, I might not use its full power. Some attachments, like breaker hammers or augers, need a lot of flow. Others, like buckets, need less.

Attachment Type | Flow Needed (GPM) | Pressure (PSI) | Notes |

|---|---|---|---|

Hydraulic Breaker | N/A | Needs strong flow for power | |

Plate Compactor | High | N/A | Needs steady flow, less noise |

Auger | Up to 30 | N/A | For deep drilling |

I also look for machines with extra hydraulic circuits. These help me run more types of attachments. I keep an eye on hoses and fittings, too, so everything stays safe and works well.

Coupler Systems

Quick couplers make my life much easier. I can switch attachments fast, right from the cab. I use quick couplers with safety locks and visual checks so I know my attachments are secure. There are different types, like standard hydraulic, dual lock, and automatic. Dual lock couplers give me double safety, and automatic ones lock themselves, which saves me time and worry.

Coupler Type | Key Feature | Safety Level | Efficiency Boost |

|---|---|---|---|

Standard Hydraulic | Cab-operated | High | Significant |

Dual Lock | Double locking | Very High | High |

Automatic | Self-locking | Highest | Maximum |

I always check if my attachments and quick couplers match. DeepKron’s attachments work with most coupler systems, so I don’t have to buy extra adapters. This saves me money and keeps my projects moving.

Tip: I always check the specs for both my mini excavator and my attachments. This helps me avoid problems and keeps my work safe and smooth.

Key Features

Durability

When I choose attachments for my mini excavator, I always look for durability first. I want tools that last a long time and can handle tough jobs. I trust brands that use high-quality materials and have a good reputation. For example, I read about tests where engineers used simulations and real field tests to check the strength of buckets. The results matched closely, with less than 5% error. This tells me the attachments will hold up under hard work. I also know that some brands use hardened steel and wear-resistant parts, so the attachments stay sharp and strong even after many hours. Durability means I spend less on repairs and replacements, which saves me money in the long run.

Maintenance

Keeping my attachments in top shape is important to me. I follow a simple routine every day. I check fluid levels, look at the air filters, and inspect the pivot pins. I also make sure the track tension is right. I change the oil and filters every 500 hours and check the hydraulic oil every 5,000 hours. I keep a log of all my service dates and repairs. This helps me spot problems early and plan when to do bigger maintenance jobs. Many new attachments have easy-to-reach parts and digital alerts, so I know when something needs attention. Good maintenance keeps my attachments working well and helps me avoid big breakdowns.

Multi-Functionality

I love using attachments that can do more than one job. Multi-functionality is one of my favorite features. With the right attachments, I can dig, lift, break, and clear land without switching machines. Some attachments let me use two tools at once or switch between them quickly. This makes my work faster and easier. I have seen attachments that fit many types of mini excavators and work with different coupler systems. This means I can use the same attachments on different jobs and machines. Multi-functionality helps me finish projects on time and keeps my clients happy.

Here is a quick list of why these features matter to me:

Durability means less downtime and lower costs.

Easy maintenance keeps attachments ready for work.

Multi-functionality lets me do more with fewer tools.

Tip: I always pick attachments with strong features that match my needs. This way, I get the best results on every project.

Ideal Excavator Attachment Selection

Assess Options

When I look for the ideal excavator attachment, I start by thinking about what my project needs. I ask myself questions like, “What kind of ground will I work on?” and “How deep do I need to dig?” I also check if my mini excavator has enough hydraulic power for the attachments I want to use. I always make sure the attachment fits my machine. Universal attachments are common, but I double-check the specs to avoid surprises.

Here’s how I break down my choices:

I match the attachment to the job. For example, I use a grapple bucket for debris and an auger for drilling.

I check my machine’s size, weight, and engine power.

I think about how often I will use the attachment.

I look at my budget and see which options give me the best value.

I consider how easy it is to maintain the attachment.

I also look for attachments that make my work easier and faster. Versatility matters to me. I like attachments that can handle more than one task. This way, I get more done with less effort.

Factor | Why It Matters |

|---|---|

Machine Specs | Ensures safe and smooth operation |

Project Type | Matches the tool to the job |

Frequency of Use | Helps decide on investment level |

Hydraulic Power | Makes sure the attachment works well |

Maintenance Needs | Keeps downtime low |

Consult Experts

Sometimes, I feel unsure about which attachment to pick. When that happens, I talk to experts or suppliers. They know a lot about different excavator attachment options and can help me find the best fit. I share details about my project, like the site conditions and what I want to achieve. They often ask about my machine’s specs and what kind of work I do most.

I trust brands with a strong reputation, like DeepKron, because they offer advice and support. Their team helps me match the right attachment to my needs. I also read reviews and ask other operators about their experiences. This helps me avoid mistakes and choose the ideal excavator attachment for my job.

Tip: Don’t be afraid to ask questions. The right advice can save you time, money, and trouble on your next project.

Maintenance and Safety

Regular Checks

I always make regular checks a top priority before I use my mini excavator attachments. These checks help me spot problems early and keep my equipment running smoothly. I follow a step-by-step checklist every day. I look at the hydraulic systems, brakes, and fuel systems. I also inspect the bolts and nuts on my attachments and make sure nothing is loose or worn out.

Here’s a quick look at my maintenance schedule for attachments:

Interval | What I Check on Attachments |

|---|---|

Daily | Visual inspection, clean surfaces, check for leaks |

Lubricate pins, check teeth, adjust tension | |

50 Hours | Inspect couplers, replace filters, check controls |

100 Hours | Change oil, check hydraulic lines, inspect wear |

I keep a log of every service and repair. This helps me track the history of my attachments and plan for bigger maintenance jobs. I also ask my team to sign off on each checklist. This keeps everyone accountable and makes sure nothing gets missed.

Tip: I update my checklists often. I use feedback from my team and new data from the job site to make sure my maintenance routine stays effective.

Safe Operation

When I use attachments, I always put safety first. I start by making sure I have the right training for each tool. I check that every attachment is locked in place before I begin work. I never use attachments that are too heavy for my mini excavator. I also look around the job site for hazards like power lines or uneven ground.

Here’s my go-to safety routine for attachments:

Inspect all safety devices and controls before starting.

Secure hydraulic couplers and double-check locks.

Keep the cab clean and make sure I can see clearly.

Always wear my seatbelt and use the three-point method to get in and out.

Stay aware of my surroundings and mark safe zones.

Never swing the cab or bucket when loading to avoid tipping.

Place dirt and debris away from trench edges.

Store attachments in a dry, stable spot after use.

Clean attachments and check for damage before putting them away.

Use rated tie-downs when transporting attachments.

I learned that following these steps helps prevent accidents and keeps my team safe. I also know that collecting operation records and maintenance logs after each shift helps me find and fix problems fast. When I stick to these safety habits, I see fewer breakdowns and a safer job site.

Note: Safe operation and regular checks for attachments are not just good habits—they are the best way to protect my team and get the job done right.

When I pick the right attachments for my project, things go better. I always think about what I need and talk to DeepKron experts before choosing. Good attachments help me work faster, save money, and keep my team safe. I have used buckets, augers, and breakers to do many jobs with one machine. Attachments let me change tasks quickly, use less fuel, and spend less. I trust attachments to make my work better, help me be more exact, and keep clients pleased. Attachments help me with hard jobs, protect my machine, and finish on time. I always check if my attachments fit well and are strong. DeepKron attachments make me feel ready for any project. If you want your mini excavator to do more, think about what you need and look at DeepKron’s attachments today.

FAQ

What attachment do I use for digging in rocky soil?

I always pick a heavy-duty bucket or a ripper for rocky ground. These tools break up tough soil and make digging easier. DeepKron’s buckets and scarifiers work great for this kind of job.

Can I switch attachments by myself?

Yes, I can switch most attachments on my own. Quick couplers make it fast and safe. I just follow the steps in my manual and double-check the locks before I start working.

How do I know if an attachment fits my mini excavator?

I check my machine’s specs and compare them to the attachment’s requirements. I look at weight, size, and hydraulic flow. DeepKron’s universal design helps me fit their attachments to most mini excavators.

What maintenance do mini excavator attachments need?

I clean my attachments after each use. I check for loose bolts, leaks, and worn parts. I also grease moving parts and follow the service schedule. Regular care keeps my tools working longer.