You rely on your mini excavator for tough jobs, so you need every component to perform at its best. The oil pump radiator plays a critical role in keeping your machine cool and efficient. Without a properly functioning oil pump radiator, your mini excavator faces overheating, rapid wear, and costly repairs. Machines like the DeepKron DK16P show how robust design and efficient cooling make a real difference in durability.

Key Takeaways

Oil pump radiators keep hydraulic oil cool, preventing overheating and protecting your mini excavator’s parts.

Regularly clean and inspect the radiator fins and hoses to maintain strong airflow and avoid heat buildup.

Choose the right radiator type—air-to-oil for most jobs or water-to-oil for tougher conditions—to match your machine’s needs.

Proper radiator placement and secure installation help maximize cooling and protect components from damage.

Watch for signs of overheating like strange noises, slow movements, or high oil temperatures and act quickly to fix issues.

Maintaining the cooling system extends the life of seals, hoses, and pumps, reducing breakdowns and repair costs.

Follow a routine maintenance plan with regular checks, cleaning, and coolant changes to keep your mini excavator reliable.

Using quality parts and following manufacturer guidelines ensures your radiator works efficiently and supports long-term durability.

Oil Pump Radiator Basics

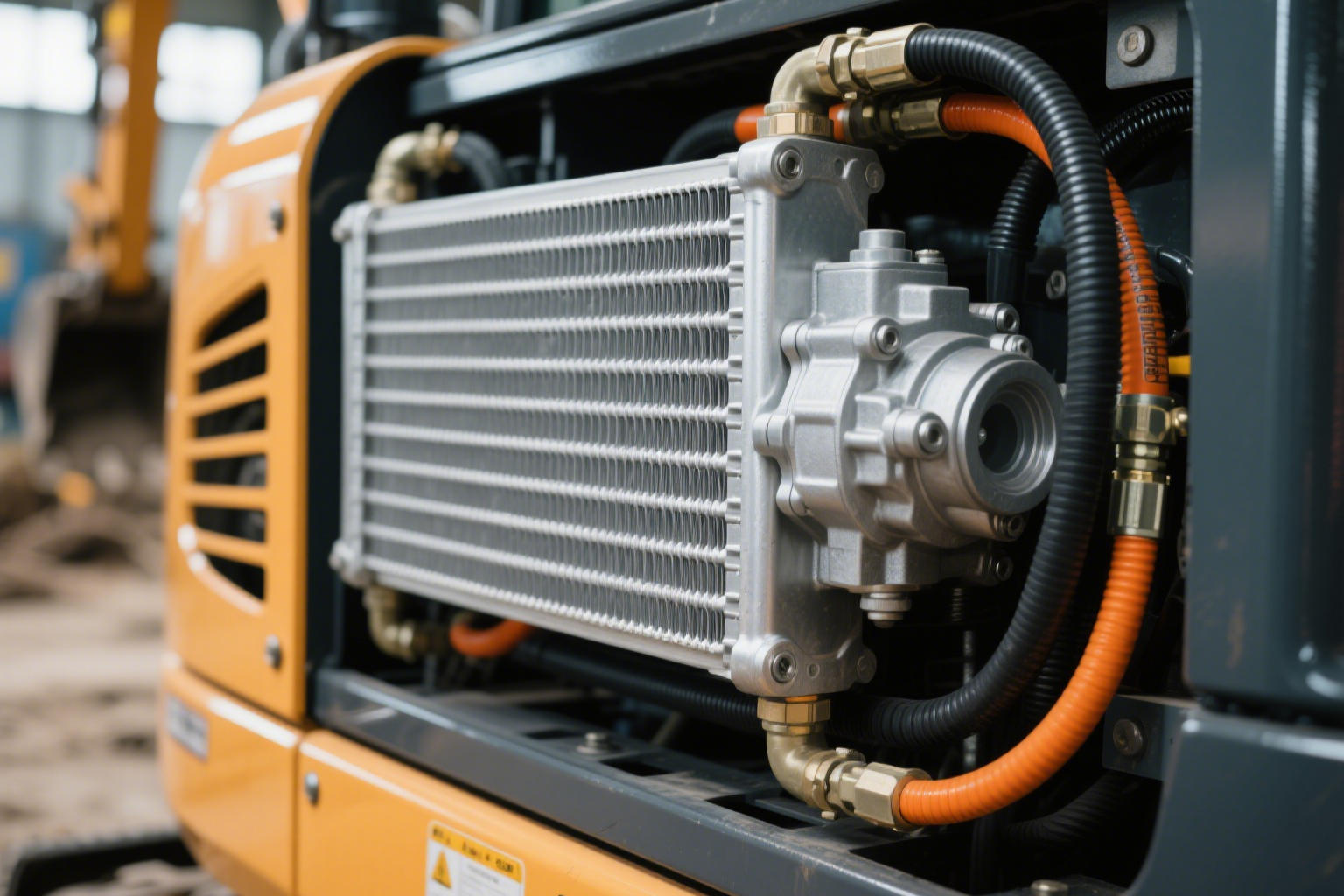

What Is an Oil Pump Radiator

You depend on your mini excavator’s hydraulic system to deliver consistent power and control. The oil pump radiator is a specialized component that manages the temperature of hydraulic oil as it circulates through the system. By keeping the oil temperature within a safe range, the radiator prevents overheating and protects the quality of the oil. This function is essential for the safe and efficient operation of your mini excavator. When you maintain the correct operating temperature, you help ensure that pumps, valves, and actuators work smoothly and last longer.

Tip: Regularly check your oil pump radiator for debris or blockages. Clean it as part of your routine maintenance to avoid overheating issues.

How It Works

The oil pump radiator operates by transferring heat away from the hydraulic oil. As the oil moves through the system, it absorbs heat from working components. The radiator uses either air or liquid to cool the oil before it returns to the hydraulic circuit. This process keeps the oil temperature stable, which is critical for maintaining oil quality and system performance. Sensors and filters often work alongside the radiator to monitor and maintain both cleanliness and temperature. When you keep the oil at the right temperature, you reduce the risk of damage to seals, hoses, and other vital parts.

The radiator manages hydraulic fluid temperature to prevent overheating.

It works with filters and sensors to keep oil clean and the system safe.

Proper maintenance includes cleaning the radiator to avoid temperature spikes.

The hydraulic system relies on the radiator to keep pumps, valves, and actuators running efficiently.

Types

You can choose from different types of oil pump radiators, each with unique cooling methods and installation requirements. The most common options for mini excavators are air-to-oil and water-to-oil coolers. Here’s a quick comparison:

Type of Cooler | Cooling Method | Cooling Efficiency | Typical Use Case | Installation Complexity |

|---|---|---|---|---|

Air-to-Oil Cooler | Uses ambient air blown by a fan across a finned radiator | Efficient for mobile outdoor equipment | Most common in mini excavators | Relatively simple |

Water-to-Oil Cooler | Uses liquid coolant to transfer heat away from hydraulic oil | Higher efficiency when air cooling is insufficient | Less common in smaller machines | More complex due to integration |

Air-to-oil coolers suit most mini excavators because they offer reliable performance and simple installation. Water-to-oil coolers provide higher cooling efficiency, especially in demanding conditions, but require more complex integration. When you select the right type, you help your machine maintain the ideal operating temperature and extend its service life.

Radiator Role in Mini Excavators

Hydraulic System Overview

You rely on your mini excavator’s hydraulic system for every movement and function. This system uses pressurized oil to power the boom, arm, bucket, and other attachments. Hydraulic pumps draw oil from a reservoir and send it through hoses to cylinders and motors. The system must maintain the right temperature to work efficiently. High-performance machines like the DK16P use advanced hydraulics to deliver smooth, precise control. When you operate in tough conditions, the hydraulic system faces heavy loads and heat buildup. Keeping the oil cool becomes essential for both performance and durability.

Radiator Placement

You find the oil pump radiator in a strategic location on your mini excavator. Manufacturers place it where airflow is strongest, often near the engine compartment or along the side panels. This placement allows ambient air to pass over the radiator fins, cooling the oil as it circulates. Proper radiator placement prevents overheating and ensures the hydraulic system stays within safe temperature limits. On the DK16P, the robust build and protected components help shield the radiator from debris and impact. You benefit from a design that balances cooling efficiency with component protection.

Tip: Always check that nothing blocks the airflow around your radiator. Even a small obstruction can reduce cooling performance and raise hydraulic oil temperatures.

System Integration

Integrating an oil pump radiator into your mini excavator’s hydraulic system requires careful planning. You must ensure mechanical compatibility with the frame and hose fittings. Secure mounting prevents vibration damage, so use strong brackets and bolts. Routing hydraulic hoses correctly is critical. Pressure-rated hoses help avoid leaks and pressure drops. Position the cooler where air can flow freely, and avoid blocking it with other components. Water-to-oil coolers need extra connections, making integration more complex. After installation, purge air from the hydraulic system to prevent operational issues. Always match the radiator’s capacity with your hydraulic flow rates for effective cooling. If you use aftermarket or pre-owned coolers, check for warranty coverage. Troubleshooting leaks and pressure drops often involves inspecting hose fittings and seals.

Ensure mechanical compatibility with your mini excavator’s frame.

Use secure mounting to prevent vibration damage.

Route hydraulic hoses with care to avoid leaks.

Position the cooler for maximum airflow.

Purge air from the system after installation.

Match the radiator to your hydraulic flow rates.

When you follow these steps, you help your mini excavator’s hydraulic system run cooler and last longer. The DK16P’s integrated design demonstrates how proper radiator placement and system integration support both performance and durability.

Overheating Problems

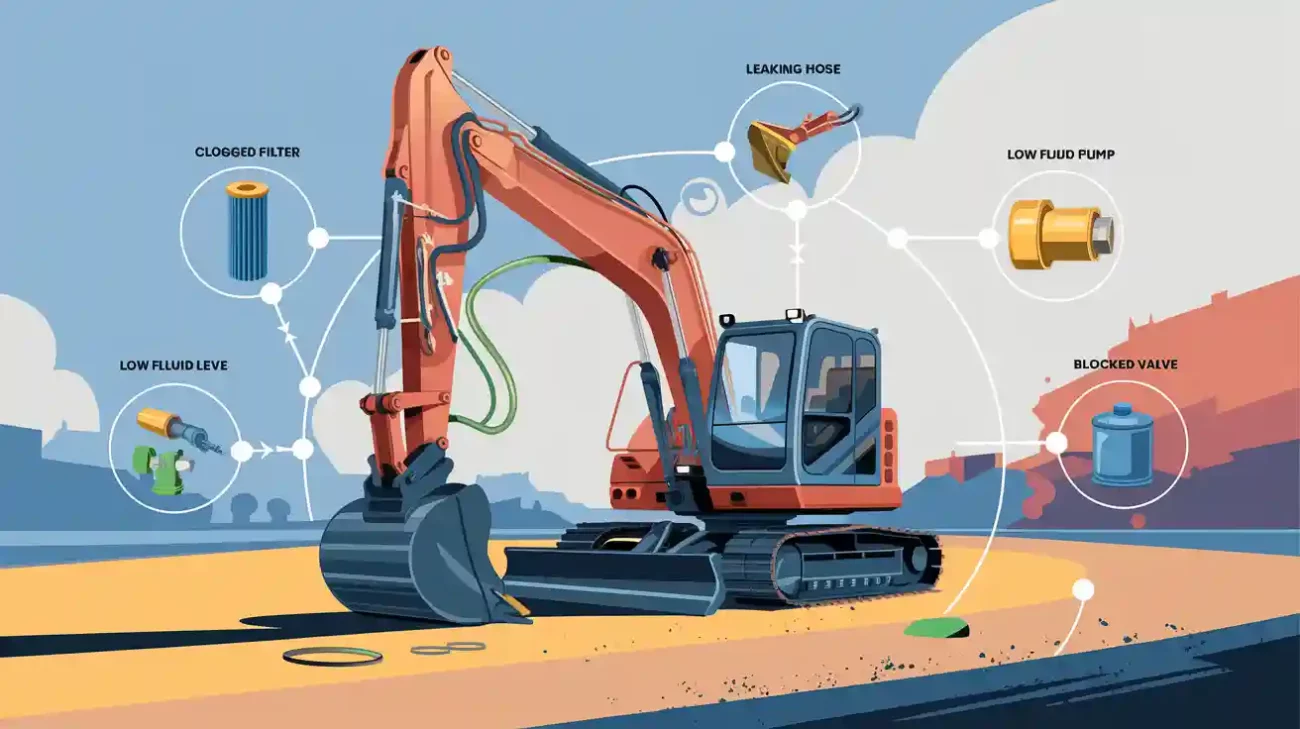

Hydraulic System Overheating

You face hydraulic system overheating when your mini excavator works under heavy loads or poor maintenance conditions. This problem often starts with leaks, worn-out parts, or contaminated oil. When you use incorrect or heavy attachments, you increase pressure and heat in the hydraulic system. Dirty or damaged radiators and fans reduce cooling performance, causing heat to build up quickly. Battery issues and overworking the machine beyond recommended operating times also contribute to overheating.

Leaks and worn parts force the system to work harder, generating more heat.

Overloading with heavy attachments increases pressure and temperature.

Poor maintenance leads to hydraulic system overheating.

Dirty radiators and fans reduce heat dissipation.

Battery problems and excessive use cause heat buildup.

The DeepKron DK16P mini excavator uses advanced cooling and robust components to minimize overheating risks. You benefit from a design that keeps oil temperature stable, even during demanding jobs.

Effects on Durability

Overheating damages critical hydraulic components and shortens their lifespan. When the hydraulic fluid temperature rises above safe levels, seals and hoses deteriorate quickly. Rubber seals lose flexibility and start leaking, while hoses age faster and may fail under pressure. Hydraulic pumps suffer from cavitation and contamination, which cause internal wear and reduce fluid pressure. If you ignore these problems, you risk cascading failures throughout the hydraulic system.

Component | Effect of Overheating | Durability Impact |

|---|---|---|

Hydraulic Seals | Rubber breaks down due to temperature and pressure changes | Leaks and pressure loss, shorter seal life |

Hydraulic Hoses | Extreme heat degrades rubber compounds | Faster aging and hose failure |

Hydraulic Pumps | Cavitation and contamination cause internal wear | Reduced pressure, pump failure |

You protect your mini excavator’s durability by keeping the hydraulic system cool and maintaining proper oil temperature. The DK16P’s design helps you avoid these common failures and extend component life.

Signs of Overheating

You can spot hydraulic system overheating by watching for several warning signs. Elevated hydraulic fluid temperature signals excessive friction and heat buildup. Unusual noises, such as whining, knocking, or rattling, often indicate cavitation or worn parts. Pressure fluctuations and reduced flow rate show instability in the hydraulic system. Physical damage, like pitting or erosion on pump components, points to overheating or cavitation. Performance drops, including decreased output pressure and irregular flow, reveal deeper problems.

Tip: If you notice any of these signs, stop the machine and inspect the cooling system. Addressing overheating early prevents costly repairs and downtime.

You keep your mini excavator running efficiently by monitoring these signs and maintaining the cooling system. The DK16P’s high-performance hydraulics and protected radiator help you avoid overheating and maintain peak performance.

Oil Pump Radiator Solutions

Cooling Process

You need a reliable cooling process to keep your mini excavator running smoothly. The oil pump radiator uses two main methods to remove heat from the hydraulic oil: air-to-oil and water-to-oil coolers. Air-to-oil coolers work best for outdoor mini excavators. A fan blows ambient air across a finned radiator, pulling heat away from the oil and maintaining stable temperature. Water-to-oil coolers use liquid coolant to transfer heat, which increases cooling efficiency in demanding conditions. You must match the cooler’s capacity to your excavator’s hydraulic output to avoid unnecessary energy use and ensure effective cooling.

Tip: Clean the radiator fins and check temperature sensors regularly. Dirt and debris block airflow and reduce cooling efficiency.

Key steps for effective cooling:

Position the cooler where airflow is strongest.

Secure brackets to prevent vibration.

Route hoses correctly to avoid leaks.

Monitor temperature sensors for early signs of overheating.

When you follow these steps, you maximize the cooling process and protect your hydraulic system from heat damage.

Preventing Hydraulic System Overheating

You face overheating risks every time your mini excavator operates under high pressure or heavy loads. Hydraulic oil absorbs heat from friction and pressure, and if the temperature rises above safe limits, you risk system failure. The oil pump radiator acts as a heat exchanger, dissipating heat and keeping the hydraulic fluid within safe temperature ranges. You prevent overheating by checking oil levels, cleaning coolers, and reducing workload when necessary.

Common causes of overheating:

Internal leakage in the hydraulic system.

Clogged coolers that restrict airflow.

Low oil levels that reduce cooling capacity.

How you prevent overheating:

Inspect and clean radiator fins and fans to maintain airflow.

Replace degraded oil to support temperature control.

Use high-quality hydraulic fluid for better heat resistance.

Stop the machine and check cooling components if you notice slowed movements or unusual noises.

Note: Signs of overheating include foamy or milky fluid, slowed hydraulic movements, and strange sounds. Immediate action helps you avoid costly repairs.

Proper maintenance of the cooling system ensures your mini excavator stays reliable and efficient, even during demanding jobs.

Extending Component Life

You extend the life of your mini excavator’s components by maintaining optimal oil temperature and preventing overheating. The oil pump radiator regulates hydraulic oil temperature, preventing breakdown and degradation. When you keep the system cool, you protect seals, hoses, and pumps from heat damage. Radiators improve system efficiency and responsiveness, reducing downtime and maintenance costs.

Component | Benefit of Proper Cooling | Result for You |

|---|---|---|

Hydraulic Seals | Maintains flexibility and integrity | Fewer leaks, longer seal life |

Hydraulic Hoses | Prevents premature aging | Reliable performance, less risk |

Hydraulic Pumps | Reduces internal wear | Consistent pressure, durability |

You gain more uptime and lower repair costs when you invest in regular radiator maintenance. Machines like the DK16P use advanced cooling systems to help you achieve maximum durability and efficiency.

Callout: Regular inspection and cleaning of your oil pump radiator are essential steps to extend the life of your mini excavator’s hydraulic components.

Benefits for Mini Excavator Maintenance

Regular mini excavator maintenance stands as the foundation for long-term durability and reliable performance. When you focus on the importance of mini excavator maintenance, you protect your investment and keep your machine working at its best. The DeepKron DK16P, with its robust build and easy-access components, shows how thoughtful design supports maximum uptime and straightforward maintenance routines.

Fewer Breakdowns

You want your mini to stay on the job, not in the repair shop. Oil pump radiators play a key role in reducing breakdowns by keeping hydraulic oil at the right temperature. When the oil stays cool, you avoid overheating, which can quickly damage seals, hoses, pumps, and valves. Here’s how oil pump radiators help you experience fewer breakdowns:

They regulate hydraulic oil temperature, preventing heat-related wear.

Cooler oil slows down oil degradation and keeps the system responsive.

You see fewer overheating issues, especially during heavy use, with temperature drops of up to 20°F reported after installing coolers.

Extended component lifespan and reduced downtime become the norm.

Improved fuel efficiency and lower emissions support overall machine reliability.

With a mini like the DK16P, you benefit from a cooling system designed to keep your excavator running smoothly, even in tough conditions.

Lower Maintenance Costs

You save money when your mini needs fewer repairs and less frequent part replacements. Oil pump radiators help you achieve this by maintaining optimal hydraulic oil temperature. When the system runs cooler, you reduce the frequency of oil changes and avoid premature wear on expensive components. This means you spend less on seals, hoses, and pumps over the life of your excavator.

Tip: Schedule regular checks of your radiator and cooling system. Early detection of blockages or leaks prevents costly repairs down the line.

The DK16P’s design makes it easy for you to access and service key components, streamlining your maintenance tasks and minimizing downtime.

Improved Efficiency

You notice a real difference in how your mini performs when the hydraulic system stays cool. Oil pump radiators ensure that the hydraulic oil does not overheat, which keeps the system responsive and smooth. This leads to faster cycle times and more precise control, especially during demanding jobs.

Regulated oil temperature prevents seal and hose degradation.

Smoother and faster system response improves operational efficiency.

Lower operating temperatures mean fewer unexpected breakdowns.

You spend less time on maintenance and more time getting work done.

The DK16P’s advanced cooling and hydraulic systems work together to deliver consistent efficiency, helping you complete projects on schedule and with less hassle.

Callout: Prioritizing mini excavator maintenance and investing in quality cooling systems like oil pump radiators pays off with fewer breakdowns, lower costs, and better performance.

Importance of Mini Excavator Maintenance

Routine Checks

You protect your investment and keep your machine running smoothly by following a regular maintenance plan. Routine checks help you catch small issues before they become major problems. Start each day with a visual inspection. Look for leaks, cracks, or rust on the radiator and hydraulic lines. Check oil levels in both the engine and hydraulic tank. Low oil can lead to overheating and damage. Examine hoses and clamps for wear or looseness. Replace any damaged parts right away.

A best practice for optimal maintenance is to follow a checklist. Here are key steps you should include:

Check and clean radiator fins to ensure proper airflow.

Inspect and replace radiator hoses and clamps as needed.

Examine the radiator for blockages or leaks.

Maintain appropriate coolant levels.

Drain, flush, and refill coolant or add coolant extender as recommended.

Change the radiator coolant at scheduled intervals.

Monitor hydraulic oil tank fluid levels, leakage, and damage.

Drain water and sediment from the hydraulic tank.

Perform oil change and filter replacement as part of routine service.

Check and replace hydraulic pump, suction, and pressure hoses if necessary.

Inspect and repair or replace hydraulic fluid lines and tubelines.

By sticking to a regular maintenance plan, you reduce the risk of clogged coolers and extend the life of your mini excavator.

Radiator Care

Proper radiator care is essential for keeping your cooling system efficient. You should never open or inspect the radiator while the engine is running or hot. Wait until it cools to avoid injury from pressurized coolant. Keep coolant fresh and change it at intervals recommended by the manufacturer. Avoid mixing different types of coolant.

Tip: Remove debris daily from radiator screens, especially during warm months. This daily maintenance step helps maintain airflow and cooling efficiency.

Use compressed air or a soft brush to clean your cooler and radiator fins. High-pressure water or steam should only be used if necessary, as they can deform the radiator. Inspect the radiator cap when the system is cool. Replace it if you find cracks or damage. Secure the cap firmly after inspection. When using hydraulic attachments, monitor the machine closely. These tools increase the load on the cooling system and raise the risk of overheating.

Maintenance Tips

You can prolong the life of your oil pump radiator by following a few best practices for optimal maintenance. Clean the radiator surface by blowing compressed air from the back to remove dust and debris. Avoid high-pressure water guns, which can deform the radiator. In dusty environments, install a dust screen (30-50 mesh) on the radiator. Clean the screen after each shift.

Use special water tank cleaning agents to remove oil stains. Circulate the diluted agent for about 20 minutes, then rinse with clean water. Upgrade your air filter by adding a pre-filter and maintain it by blowing it every 50 hours and replacing it every 200 hours in harsh conditions. Regularly inspect and replace hydraulic oil and filters. Keep related components clean and lubricated to support radiator longevity.

🛠️ Note: A regular maintenance plan that includes these steps will help you avoid costly repairs and keep your mini excavator performing at its best.

You see the importance of mini excavator maintenance in every job you complete. By making these checks and care steps part of your routine, you ensure your machine stays reliable and efficient for years to come.

Choosing and Maintaining Oil Pump Radiators

Selection Factors

You need to choose an oil pump radiator that matches your mini excavator’s hydraulic system and job requirements. Start by checking the cooling capacity. Select a radiator that can handle the maximum hydraulic flow and pressure your machine produces. Material matters. Aluminum radiators work well for general use, while copper radiators offer better resistance in harsh environments. Always verify compatibility with your excavator’s model and hydraulic specifications.

Common mistakes during selection include picking attachments that exceed your machine’s hydraulic flow or using undersized quick couplers. These errors lead to overheating and reduced efficiency. You should also avoid radiators with bent fins or signs of corrosion, as these issues lower cooling performance. Manufacturer guidelines, such as those from DeepKron, recommend using ISO-compliant coolants and matching radiator materials to your operating environment.

Tip: Always consult your mini excavator’s manual and manufacturer recommendations before purchasing a new radiator. This ensures proper fit and optimal performance.

Selection Criteria | Why It Matters |

|---|---|

Cooling Capacity | Prevents overheating |

Material (Aluminum/Copper) | Matches job site conditions |

OEM Compatibility | Ensures proper fit and function |

Hydraulic Flow Rating | Supports system efficiency |

Attachment Matching | Avoids excess heat and wear |

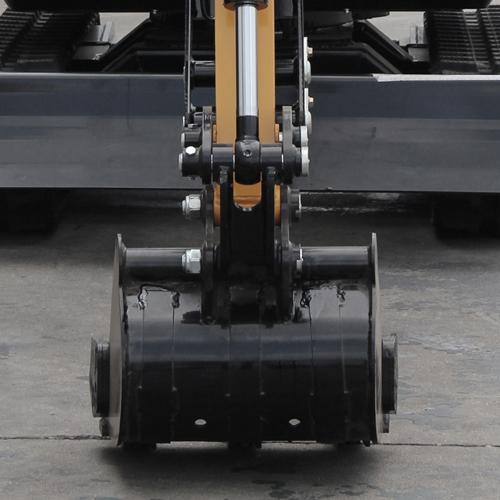

Installation

Proper installation of your oil pump radiator is essential for reliable cooling and long-term durability. Begin by inspecting hoses, clamps, and mounting brackets for wear or damage. Use secure brackets to prevent vibration and leaks. Flush the hydraulic system before installing the new radiator to remove debris and old coolant. Position the radiator where airflow is strongest, usually near the engine compartment or side panels.

Follow manufacturer instructions for torque settings and safety precautions. DeepKron and other leading brands recommend waiting for the engine to cool before starting installation. Use the correct tools, such as a ratchet set and torque wrench, to avoid damaging components. After installation, test for leaks and monitor temperature stability during operation.

Regulate hydraulic oil temperature to prevent overheating.

Extend the lifespan of seals, hoses, pumps, and valves.

Improve operational efficiency and reduce maintenance costs.

Prevent common issues like coolant leaks and reduced cooling efficiency.

🛠️ Note: Professional installation is recommended for complex models or severe damage. Always use OEM parts for best results.

Ongoing Care

You maintain peak performance by caring for your oil pump radiator every day. Clean radiator fins with a soft brush or compressed air to remove dirt and debris. Use eco-friendly detergents for deeper cleaning. Straighten bent fins carefully to maintain airflow. Check for corrosion, gasket failures, and slow leaks during routine inspections.

Flush the cooling system annually and use ISO 24365-compliant coolants to prevent internal corrosion. Monitor hydraulic oil quality and levels, replacing oil and filters as needed. Inspect hoses, couplers, and seals for signs of wear or damage. Store attachments and your mini excavator in clean, dry conditions to avoid contamination.

Callout: Following manufacturer guidelines, such as those from DeepKron, aligns your maintenance routine with industry standards. This approach helps you avoid costly repairs and ensures your mini excavator stays durable and efficient.

By selecting the right radiator, installing it correctly, and maintaining it regularly, you protect your investment and keep your mini excavator running at its best.

Oil pump radiators give you a clear advantage in mini excavator durability and cost control. When you follow a routine maintenance schedule, like inspecting coolant levels every 8-10 hours and cleaning radiator fins, you keep your machine running strong. The DK16P shows how smart design and easy access support these habits.

Maintenance Task | Recommended Frequency |

|---|---|

Every 8-10 hours of operation | |

Replace radiator coolant | Every 2,000 hours |

Clean radiator fins | Regularly |

Check for leaks or blockages | Regularly |

Inspect hoses and clamps | Regularly |

You should assess your equipment, upgrade radiators when needed, and choose quality parts for long-term reliability. Regular care and informed decisions help you avoid breakdowns and extend your mini excavator’s life.

FAQ

What does an oil pump radiator do in a mini excavator?

You use an oil pump radiator to keep hydraulic oil cool. This prevents overheating, protects seals and hoses, and helps your mini excavator run smoothly. A well-maintained radiator extends the life of your machine’s hydraulic system.

How often should you clean your oil pump radiator?

You should check and clean your radiator fins daily, especially in dusty conditions. Remove debris with compressed air or a soft brush. Regular cleaning keeps airflow strong and cooling efficient.

What are signs that your radiator needs attention?

You may notice higher hydraulic oil temperatures, slower machine response, or strange noises. Leaks or visible debris on the radiator also signal problems. Address these issues quickly to avoid costly repairs.

Can you install an aftermarket oil pump radiator on your mini excavator?

Yes, you can install an aftermarket radiator if it matches your machine’s hydraulic flow and pressure. Always follow manufacturer guidelines and use quality parts for best results.

How does the DK16P make radiator maintenance easier?

The DK16P features easy-access panels and protected components. You reach the radiator quickly for cleaning and inspection. This design helps you complete maintenance tasks faster and keeps your machine running longer.

What type of coolant should you use in your radiator?

You should use coolant that meets your mini excavator manufacturer’s specifications. ISO-compliant coolants work best. Never mix different coolant types, as this can reduce cooling performance.

Why does radiator placement matter?

Proper radiator placement ensures strong airflow and effective cooling. Manufacturers like DeepKron position radiators where they stay protected but still get enough air. Good placement helps prevent overheating and extends component life.

How do you know when to replace your oil pump radiator?

You should replace your radiator if you see corrosion, bent fins, or persistent leaks. Reduced cooling performance or frequent overheating also indicate it’s time for a new radiator.