You can help your mini excavator work well in winter by performing essential mini excavator winter maintenance. Regular winter maintenance ensures your mini excavator is safer and more reliable.

Check the engine oil, hydraulic fluid, and coolant to ensure they are suitable for winter use.

Inspect the tracks to determine if they are worn or require additional air.

Stay on top of maintenance routines to prevent your machine from stopping unexpectedly.

DeepKron provides you with trusted compact machines for these tasks.

Key Takeaways

Check your mini excavator often for leaks and wear. Make sure fluid levels are correct. This stops sudden breakdowns from happening.

Use winter-grade fluids and greases in cold weather. This helps your machine work well and keeps it running smoothly.

Keep your mini excavator in a dry, covered spot. This protects it from bad winter weather. Good storage keeps its value and helps it work right.

Preparation

Inspection

Start getting ready for winter by checking your mini excavator. Look for dents, bends, or cracks on the body and undercarriage. Make sure the engine oil, coolant, and hydraulic fluid are at the right levels. Look at the hydraulic system for leaks, especially near the pump compartment and hoses. Use a checklist to go over all the operating systems, safety devices, and parts.

Tip: Check the bucket teeth for wear, like scalloping, so you know if you need new ones soon.

DeepKron makes its machines easy to check, so you can find problems before they turn into expensive repairs.

Cleaning

Clean your mini excavator well before winter comes. Take off dirt, mud, and debris from the undercarriage and moving parts. This helps stop rust and keeps your machine working well. Drain water from the fuel tank and water separator so it does not freeze. Fill the fuel tank with fresh fuel to stop water from building up.

Change the engine oil and filters if it is almost time for maintenance.

Grease all grease points to protect them from the cold.

Attachments

Get your attachments ready for winter by doing these things:

Look at rubber parts for cracks or tears.

Use cold-weather attachments to work better on frozen ground.

Keep attachments you are not using in a dry place to stop rust.

DeepKron makes sure its machines and attachments are ready for tough winter weather. Good preparation keeps your equipment working well all winter.

Mini Excavator Winter Maintenance

Fluids

It is important to watch all fluids in winter. Cold weather makes fluids thicker. Thick fluids can slow down your machine. Always use engine oil, coolant, and diesel fuel made for cold weather.

“When it gets cold or freezing, use engine oil, coolant, and diesel fuel that work well in winter.”

Check the engine oil’s thickness. Use the type your manual says is best for winter. For coolant, mix half antifreeze and half water for most places. If it gets very cold, use more antifreeze.

Use winter diesel fuel to stop gelling and keep fuel moving.

Add fuel stabilizer or additives before it gets cold. This stops fuel from getting thick and helps your mini excavator run well.

Never put plain water in the radiator. Always use antifreeze that fits your local weather.

Check fluid levels every day. This helps you find problems early. Checking fluids is important for good mini excavator winter maintenance.

Greasing

Greasing is very important in winter. Cold weather makes regular grease thick and hard to move. Use thinner lithium grease or NLGI #1 grease when it is colder than 60°F (16°C).

Grease all pivot points, like the work arm, before you use the machine each day.

Grease on a regular schedule. Do it every 8 hours or every day if you use the machine a lot.

Look in your manual for the right grease spots and how often to grease them.

Tip: Grease in the morning to protect moving parts from wearing out. This keeps your mini excavator working well all winter.

Battery

Batteries lose power fast in cold weather. Taking care of the battery is important for mini excavator winter maintenance.

Keep your mini excavator in a warm place if you can. Cold air makes batteries weak.

Charge the battery in a warm spot. Batteries charge better when it is not freezing.

Let the machine idle for a few minutes before working. This warms up the battery and other parts.

Check battery ends for rust and make sure they are tight.

Remove snow and ice from the battery area so moisture does not cause damage.

Wrap the battery to keep it warm. This helps the battery stay strong and helps your mini excavator start every time. Wrapping also protects the battery from freezing damage.

Tracks

DeepKron builds tracks for tough winter weather. You need to check and clean the tracks every day in winter.

Look for cuts, cracks, or wear on the tracks and undercarriage.

Take off snow, ice, and dirt after each use. This stops stuff from building up and causing problems.

Check track tightness. Tracks that are too tight can crack. Loose tracks can slip or wear out fast.

Clean the undercarriage every day to stop rust or damage from salt and chemicals.

Keep your mini excavator inside or covered if you can. This keeps the tracks safe from cold and wet weather.

Checking tracks often helps you find problems early. DeepKron’s tracks work well in cold and harsh weather, so you can trust your machine in winter.

Storage

Shelter

You need to protect your mini excavator from harsh winter weather. Store your machine in a dry, covered shelter. This keeps snow, rain, and cold air away from important parts. If you have indoor storage, use it. Indoor storage helps your excavator keep its value and stops paint from chipping.

Use a high-quality tarp if you cannot store your machine inside.

Cover the exhaust pipe opening to block snow and cold air.

Lower the boom and set the bucket flat on the ground. Put all controls in the neutral position.

DeepKron machines have a durable design. This makes them strong enough for tough winter storage conditions.

Battery Storage

Batteries need special care during winter. Cold weather can drain battery power fast.

Best Practice | Description |

|---|---|

Clean the battery | Remove dirt and corrosion to stop moisture buildup. |

A full charge helps the battery last through cold months. | |

Store in insulated space | Keep the battery in a warm, dry place to prevent freezing. |

Use a battery maintainer | This tool keeps the battery charged and ready to use. |

Check for damage | Look for cracks or leaks before storing the battery. |

Disconnect the battery if you will not use the machine for a long time. This helps prevent power loss.

Attachments Storage

Take care of your attachments to stop rust and damage.

Clean every surface and let attachments dry before storing.

Check for cracks or worn parts and fix them.

Lubricate all moving joints and hinges.

Apply a rust inhibitor to metal parts.

Store attachments in a dry, well-ventilated place.

Good storage is a key part of mini excavator winter maintenance. It keeps your equipment ready for work when spring comes.

Operation

Starting

Starting your mini excavator in winter needs extra care. First, check if your oil is thick enough for cold weather. Make sure your antifreeze works when it gets very cold. Test your battery before winter comes. If the battery is weak, get a new one. Use grid heaters or glow plugs if your machine has them. Let your excavator run for five minutes before you start working. This helps the engine and fluids get warm enough. DeepKron machines have special cold start features. These features make starting in winter easier and safer.

Safety

Winter has new safety problems. Snow and ice can hide dangers in your work area. Always clear snow and ice off your machine before using it. Watch out for slippery spots and bumps in the ground. Cold weather can make diesel fuel gel and fluids get thick. Check your machine every day. Wear warm clothes to stay safe from frostbite and hypothermia. Pay attention to signs of tiredness or dehydration. These can happen faster when it is cold.

Operator Tips

You can help your mini excavator work well by doing these things:

Check tires or tracks for tightness and wear.

Warm up the engine before doing hard work.

Look at the undercarriage for rust or salt damage.

Use thick oil and check hydraulic fluids often.

Keep batteries in a warm place when not using them.

Let your machine idle in very cold weather to keep it warm.

DeepKron’s smart safety features help you work safely, even in tough winter weather.

Troubleshooting

Fuel Issues

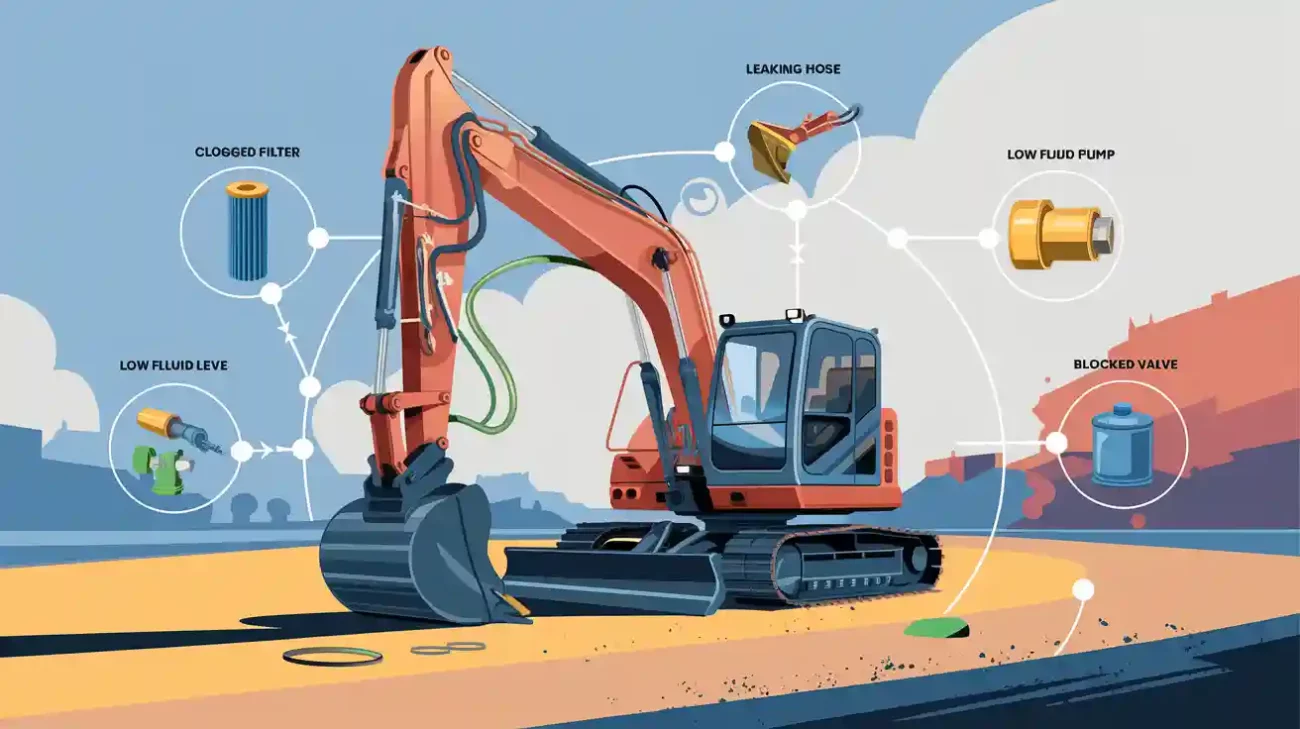

Winter can make fuel problems worse for your mini excavator. Cold weather can make fuel gel or get dirty. This can cause trouble when you try to start the engine. The engine might not run well. Here are some main reasons and fixes:

Fuel can get dirty if water, dirt, or air gets in. This can cause rust or even let germs grow.

Air in the fuel lines can make it hard to start. The engine may run rough.

You can stop these problems by doing a few things: Use good fuel from places you trust. Keep fuel in clean, closed containers. Drain water traps often so water does not build up. Change fuel filters to keep fuel moving well. Check the fuel system for rust or thick sludge. Test your fuel often to make sure it is good. Add fuel stabilizers to stop gelling and dirt.

Tip: Open the fuel shut-off valve and drain water from the tank before you start. This helps your mini excavator work better in winter.

Frozen Parts

Frozen parts can stop your mini excavator from working right. Sometimes attachments or moving parts freeze in the cold. You can fix this problem in a few ways:

Use a bigger machine if you need more power for thick ice.

Try attachments made for frozen ground, like a frost bucket or hydraulic ripper.

Use a ripper to break the hard top layer.

Hydrovac methods can help you dig easier.

Warm the ground with blankets or heaters before you start.

Cover the area at night to keep it from freezing.

Some attachments work better in winter than others. Hydraulic hammers and rotary cutters can break hard frozen ground. Static rippers help you dig through tough dirt.

Note: Doing regular mini excavator winter maintenance can stop frozen parts. This keeps your machine ready to use.

You can help your mini excavator work well in winter by doing these things: Look at the bucket teeth, hoses, and bushings to see if they are broken. Make sure all the fluids are full and the battery is working. Put away your attachments and cover your machine to keep it safe.

Checklist Item | Description |

|---|---|

Battery Care | Keep the battery in a warm, dry spot and test it before you use it. |

Track Tension | Change the track tightness often so it is safe. |

Start getting ready for winter with DeepKron equipment. This helps your machine work well when it is cold.