Yes, you can make your mini excavator last longer in winter by doing some simple things. Checking your machine every day helps you find problems early. This keeps your machine working for more years. Changing how you take care of your machine in winter protects it. This helps your mini excavator last longer. DeepKron means strong and lasting quality.

Mini Excavator Pre-Operation Checks

Before you use your mini excavator in cold weather, always check it first. These checks help you find problems early. This keeps your machine working well. DeepKron machines last a long time. Regular checks help you get the most from your machine.

Inspection

Walk around your mini excavator before you start. Look for ice or snow under the machine. Take off anything that blocks moving parts. Make sure the cab heater works so you stay warm. Look at hydraulic hoses for leaks or damage. Clean the undercarriage to stop ice from building up. Taking care of the undercarriage helps your mini excavator work well in winter.

Tip: Checking your machine often helps you find dangers like ice, snow, or bad lighting. This keeps you safe and protects your machine.

Fluid Levels

Check all fluids before you use your mini excavator. Antifreeze is very important in winter. Antifreeze stops your engine from freezing. Look at the hydraulic fluid and use winter oils. Cold weather makes fluids thicker. So, check how thick they are. Add antifreeze every day. Also, look at the fuel system and change air filters if needed.

Antifreeze

Hydraulic fluid

Engine oil

Fuel

Battery Check

Cold weather can make your battery lose power fast. Make sure your battery is charged. If it gets colder than -10°F, your mini excavator may slow down. Charge the battery all the way before you use it. Check battery connections for rust. A good battery means less waiting and better work.

Track Tension

Check the tracks in winter. Track tension is very important. If tracks are too tight, they can break. If tracks are too loose, they slip and wear out. Look for 10 to 20 mm of sag. Change the tension for your job site. Good track tension helps your mini excavator move safely and saves money on repairs.

Note: Planning for the season and checking your machine often helps you keep up with maintenance. Always use the OEM manual for best results.

Mini Excavator Maintenance Warm-Up

Engine Warm-Up

Cold weather makes engines work harder. You need to let your mini excavator warm up before you start working. Start the engine and let it idle for at least five minutes when the temperature drops below freezing. This gives the engine oil, hydraulic oil, and coolant time to reach the right temperature. You help your machine run smoother and avoid damage. If you rush, you risk problems later. Take a few minutes now, and your maintenance will be easier all season.

Tip: A warm engine means less wear and tear. You save money and keep your mini excavator running strong.

Hydraulic System

Your hydraulic system needs special care in winter. Cold oil moves slowly and can cause trouble. After you start the engine, let the hydraulic system idle for a few minutes. Move the controls gently to circulate the oil. Wait until the oil feels warm, around 60°F. This step helps all moving parts work better. Good hydraulic system maintenance keeps your machine safe and ready for tough jobs.

Attachments

Attachments need warming up too. You should prepare them before heavy work. Here’s a simple routine:

Let your machine idle longer when starting up.

Activate the attachment for five seconds, then pause for fifteen seconds. Repeat this for two to three minutes.

Move the machine slowly to warm up the whole system.

At the end of the day, let your mini excavator idle for ninety to one hundred twenty seconds before shutting down.

These steps help your attachments last longer and work better in cold weather.

Excavator Maintenance Daily Routines

Cleaning

You want your mini excavator to work well all winter. Cleaning is the first step in excavator maintenance best practices. Snow, ice, and mud can build up on the undercarriage. If you leave material there, it can freeze overnight. This stops the undercarriage from moving and may damage cylinder seals. Use a brush or scraper to clear snow and ice every day. Pay close attention to the undercarriage and tracks. Clean rubber tracks and remove any debris. Good undercarriage care keeps your machine safe and ready for service.

Tip: Always park your mini excavator on dry ground. Parking on damp ground can freeze the tracks to the surface.

Lubrication

Grease is your best friend in cold weather. You need to grease all moving parts daily. Cold can make oils thick, so use oils made for winter. ISO 68 hydraulic oil works for most jobs, but switch to ISO 46 hydraulic oil if temperatures drop below zero. Grease the pins, bushings, and joints. Don’t forget the undercarriage rollers and idlers. Grease helps stop rust and wear. If you skip this step, parts may break or stick. Grease the bucket, arm, and swing bearing. Grease the coupler and attachment points. Grease the blade and track adjusters. Grease the undercarriage after cleaning. Grease the swing motor and gear. Grease the boom and stick. Grease the pedal pivots. Grease the control linkages.

Filter Check

Filters protect your engine and hydraulic system. Check air, fuel, and hydraulic filters every day. Dirty filters can block oils and cause problems. Change filters if you see dirt or ice. Make sure the coolant mixture is right for winter. Use block heaters to help the engine start. Always use fluids and oils made for cold weather. This simple maintenance keeps your mini excavator running strong. If you follow these excavator maintenance steps, you avoid clogs and keep your machine ready for service.

Regular filter checks and daily grease help your undercarriage last longer. You save money and avoid downtime.

DeepKron Storage and Protection

Indoor Storage

You want your machine to last through the winter. Storing your equipment indoors is one of the best ways to protect it. DeepKron machines have a tough build, but cold weather can still cause problems if you leave them outside. When you keep your machine inside, you:

Protect it from snow and ice that can damage parts.

Prevent rust by keeping it dry.

Avoid condensation on metal, which can freeze and cause cracks.

Keep the value high for resale.

Make sure it’s ready to use when spring comes.

Try placing your machine on wooden planks and cover it with a tarp for extra protection. A dry, dust-free space also keeps electrical parts safe.

Tip: Covering your machine indoors helps block cold air and snow, so everything works better when you need it.

Battery Storage

Cold weather drains batteries fast. You can keep your battery strong by storing it in a warm, climate-controlled spot. Use a smart trickle charger to keep the battery charged without overdoing it. Clean the battery terminals with a baking soda solution to stop rust. Always check for cracks or damage before you store the battery. If you park your machine inside overnight, the battery stays warmer and works better. Charging your machine indoors also helps the battery last longer.

Use slower charging in winter to protect battery life.

Preheat the battery if your machine has that option.

Block Heaters

Block heaters make cold starts easier. Plug in the block heater before you start your machine on freezing days. This warms up the engine and fluids, so you avoid hard starts and reduce wear. Using a block heater means less stress on your engine and better maintenance all winter.

Note: Clean your attachments before storage. This stops ice and dirt from causing trouble later.

Winter Maintenance Tips for Safe Operation

Weather Monitoring

You need to check the weather before you start your day. Snow can hide ice and make the ground slippery. If you see snow or ice on your machine, clear it off. Remove snow from the steps so you don’t slip when you climb in. Wipe ice from the cabin windows for better visibility. When you watch the weather forecast, you know what to expect. This helps you plan your winter care routine and avoid surprises. If the forecast calls for heavy snow or freezing rain, you can adjust your schedule or take extra precautions. These essential tips keep you safe and help your equipment last longer.

Tip: Always do a quick walk-around inspection after snow falls. You might spot hidden ice or snow buildup that could affect your service.

Smooth Operation

Operating your machine in snow and cold takes skill. You want to move slowly and avoid sudden stops. Snow can cover rocks or debris, so drive carefully. Adjust your driving to account for longer stopping distances. Keep an eye on track tension because cold weather makes rubber stiff and reduces traction. If you spin the tracks, you wear them out faster. Good training helps you handle these challenges. You should also pack extra clothing to stay warm and focused. When you use the right lubricant and warm up your machine, you get better traction and smoother operation.

Maintain proper track tension for better traction.

Avoid spinning tracks in snow to extend their life.

Watch for hidden obstacles under snow.

Let your machine idle longer in cold weather.

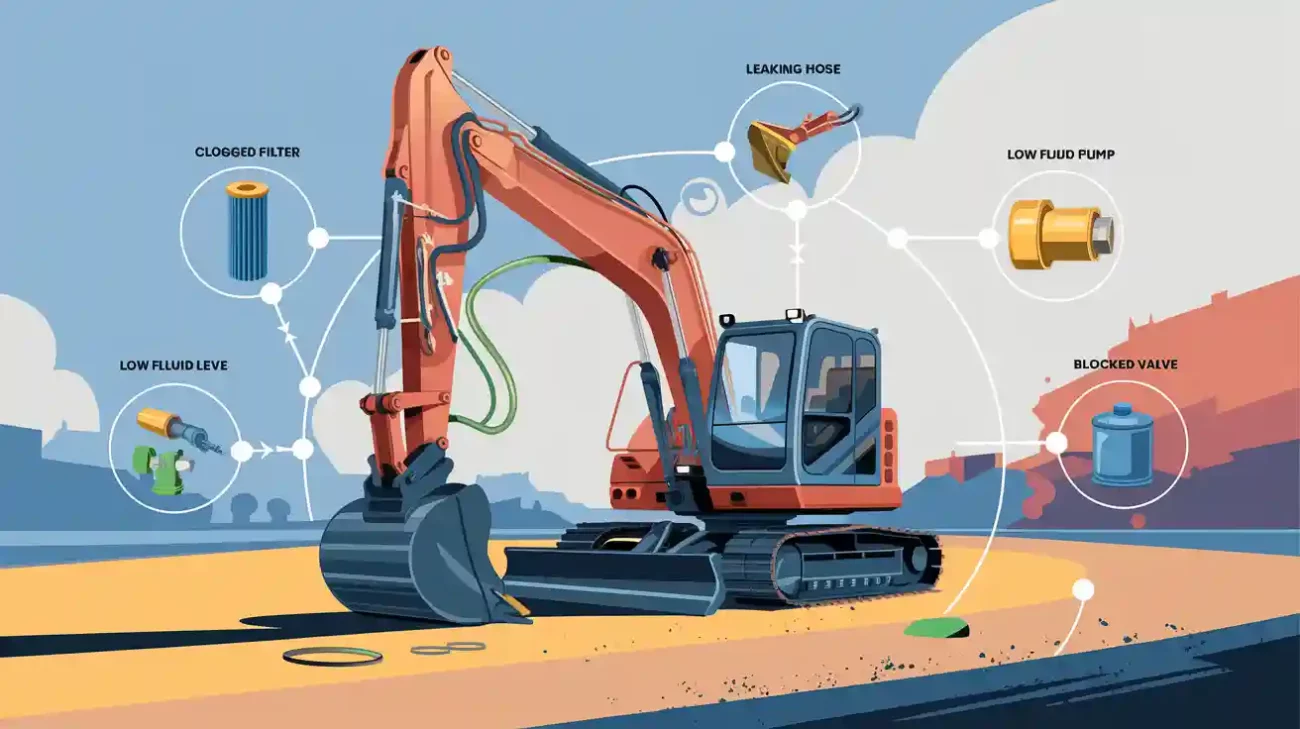

Warning Signs

You need to know what trouble looks like during winter maintenance tips. Cold can cause grease to thicken, so check moving parts for stiffness. If you notice slow response or hard starts, look at the battery and fluids. Snow and ice can damage rubber tracks, so inspect them for wear. Use winter-grade diesel to prevent fuel gelling. Always perform pre-start checks to catch problems early. The table below shows some warning signs you should watch for:

Warning Sign | Description |

|---|---|

Thickened Grease | Grease gets stiff in cold; use low-temperature grease. |

Fluid Viscosity | Oil thickens in cold; switch to winter-grade fluids. |

Cold drains batteries; keep them charged and insulated. | |

Rubber Track Wear | Snow and cold can damage tracks; inspect often. |

Pre-Start Checks | Always check before starting for safe service. |

Winter-Grade Diesel | Prevent fuel gelling in cold with the right diesel. |

Good training and daily checks help you spot these issues before they become big problems.

You can help your equipment last longer by taking care of it every day. Storing it the right way and using it safely also helps. Doing these things stops expensive repairs and keeps your machine working well. DeepKron machines have strong seals, tough hoses, and a design made for cold weather.

Strong seals and hoses stop leaks when it is very cold.

The tough design lets your machine work in hard winter weather.

Fast checks each day help your equipment last longer.

Make winter care part of your routine. Your machine will last longer each year.

FAQ

How often should you check your machine in winter?

You should check your machine every day before you start work. This helps you catch problems early and keeps your equipment running strong.

What is the best way to store your machine in cold weather?

Store your machine indoors if you can. A dry, warm space protects it from snow, ice, and rust. Cover it with a tarp for extra safety.

Can you use regular oil in freezing temperatures?

No, you should switch to winter-grade oil. Regular oil gets too thick in the cold. Winter oil helps your engine and hydraulics work better.