When you use a mini excavator, you can have problems. These include overloading, unstable ground, hydraulic leaks, operator mistakes, and missed maintenance. These issues can hurt your work and your safety. Look at this table:

Aspect | Evidence |

|---|---|

Safety | Workers need good training and the right skills to stay safe. |

Efficiency | Knowing how to use the machine safely stops accidents for many workers. |

Equipment Longevity | Doing regular maintenance, oil changes, and leak checks makes your machine last. |

Not following easy steps can cost a lot:

Overloading can break your machine and cancel your warranty.

DeepKron machinery helps you avoid these problems. Pick smart habits and good equipment for every job.

Key Takeaways

Learn your mini excavator’s lifting limits. Always look at the lift chart before you lift anything. This helps you not overload and keeps everyone safe.

Regular care is very important. Check your machine every day. Write down what you find in a log. This helps you spot problems early and makes your machine last longer.

Good training is needed for safe use. Spend time on training tools to get better skills. This lowers the chance of mistakes by the operator.

Mini Excavator Overloading

Lifting Capacity Limits

You need to know your mini excavator’s lifting capacity before you start any lifting job. If you try to lift more than your machine can handle, you risk tipping over or damaging your equipment. DeepKron mini excavators come with clear lift charts and safety features that help you stay within safe limits. Take a look at this table to see typical lifting capacity numbers for different machine weights:

Machine Weight | Max Lift Capacity (Approximate) |

|---|---|

1–2 tons | 500–1,000 lbs (226–453 kg) |

3–4 tons | 1,500–2,500 lbs (680–1,134 kg) |

5–6 tons | 2,500–4,000 lbs (1,134–1,814 kg) |

7–10 tons | 4,000–6,500+ lbs (1,814–2,948+ kg) |

If you use the lift chart for your mini excavator, you can avoid overloading and keep your lifting safe. Always check the lifting radius, because the farther out you reach, the less capacity you have.

Safe Load Practices

You want every lifting job to go smoothly. Here are some steps to help you assess load weights and follow safe lifting practices:

Check your machine’s configuration, like boom and arm length.

Measure the lift point height from the ground.

Find the lifting radius from the swing point to the load.

Use the lift chart to confirm your lifting capacity.

Tip: Terrain conditions and boom setup can change your lifting capacity. If you add counterweights, you may get better balance, but you need to set them up right. Experienced operators know how to spot instability and control the load.

If you follow these steps, you can avoid overloading and keep your mini excavator working safely. DeepKron machines make it easier for you to check lifting limits and practice safe lifting every time.

Unstable Ground Conditions

If the ground is not steady, lifting can be dangerous. Bumpy ground, hills, or soft dirt can make your machine tip over. Even a small slope can make your mini excavator less stable. If you stretch the boom or arm too far, tipping is more likely. This is a bigger risk when you are lifting things. Always look at the ground before you start lifting.

Site Leveling

You need a flat and safe place for your mini excavator. Here are some easy ways to make the ground better:

Check if the ground is too steep. Do not use your machine on slopes over 30 degrees.

Point the blade downhill and keep it just above the ground for more control.

When going uphill, keep the blade facing up and above the ground to help hold your machine.

Mark the area first so you know where to grade.

Move slowly and carefully to keep the ground flat.

Use the bucket edge to fix high spots first.

Work in small parts and check the ground with your eyes or a laser.

Try using a grading bucket or a laser tool for better results.

Tip: DeepKron mini excavators have a strong base and a design that helps them stay steady. They work well on rough ground and in small spaces.

Ground Assessment

Check the ground before you lift anything. Tools like Indicate and E-Fence help you see the slope and set safe limits. Indicate shows you the slope and how deep you are digging. E-Fence keeps your machine inside safe areas and away from danger. Swing Assist and Bucket Assist help you move the bucket and dig in the right spot.

Feature | Description |

|---|---|

Indicate | Gives you live updates on slope and depth. |

E-Fence | Sets safe limits so you avoid danger. |

Swing Assist | Helps you go back to the trench easily. |

Bucket Assist | Keeps the bucket at the right angle for lifting. |

Always look at the ground before you lift. Use these tools and tips to keep your mini excavator safe and steady, no matter where you work.

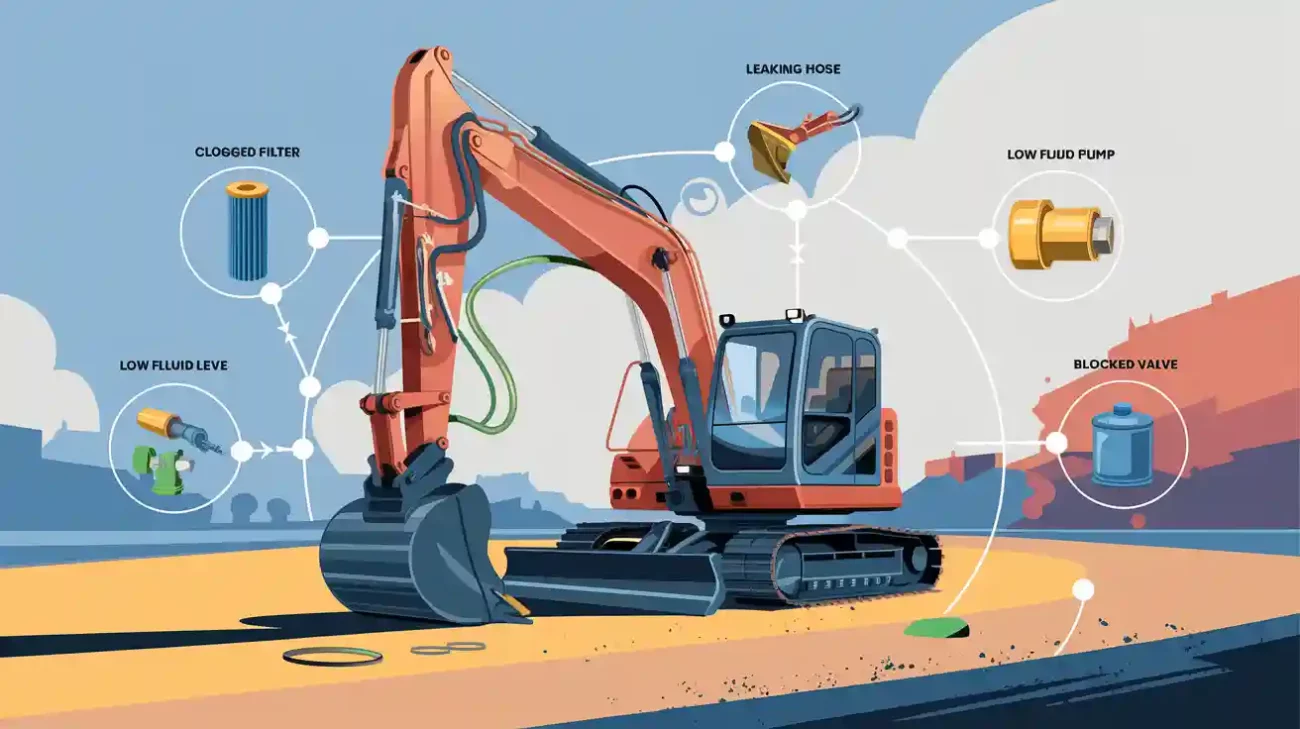

Hydraulic System Issues in Mini Excavators

Hydraulic problems can stop your mini excavator from working well. If you ignore leaks or overheating, you risk losing lifting power and slowing down your jobsite. Let’s look at the most common issues and how you can avoid them.

Hydraulic Leaks

Leaks are a big problem for mini excavators. You might see fluid under your machine or notice the lifting feels weak. Here’s a quick look at what causes leaks:

Cause | Description |

|---|---|

Loose or Damaged Fittings | Leaks often start where hydraulic lines connect to other parts. |

Failed Seals | Seals keep fluid inside. If they break, fluid escapes and lifting suffers. |

Damaged Lines | Cracked or burst lines can lose fluid fast and lower your lifting capacity. |

Fluid leaks can make your mini excavator run slow, jerk, or make strange sounds. If you spot a leak, stop and check the lift chart to see if your lifting capacity is safe. DeepKron’s maintenance support helps you find leaks early with regular inspections and daily checks. You get advice on greasing moving parts and keeping your machine ready for every load.

Overheating Prevention

Overheating can ruin your lifting job. Hot hydraulic fluid lowers your mini excavator’s lifting power and can damage parts. Here’s how you can keep things cool:

Inspect and clean the cooling system often. Dirt blocks airflow and raises fluid temperature.

Check hydraulic fluid for dirt or old oil. Change it when needed to keep lifting strong.

Match attachments to your mini excavator’s flow and pressure. Wrong tools can overheat the system and lower lifting capacity.

If you follow these steps, you protect your mini excavator and keep every lifting job safe. DeepKron’s service team gives you tips and a schedule for checks, so you never miss a step. Always check the lift chart before you start a load, and watch for signs of overheating.

Mini Excavator Operator Errors

You need skill and focus to use a mini excavator. Many accidents happen because operators make mistakes. If you skip training or hurry, you can make errors. These mistakes can put you and your team in danger. Good training helps you avoid problems and keeps lifting safe.

Training Importance

There are many ways to learn how to use a mini excavator. Some people like online training because you can learn anytime. Others use DIY kits to practice with real tools. Some companies train one person to teach the rest of the team. Here is a table with popular training choices:

Training Type | Description |

|---|---|

Online Training | Learn anywhere, anytime, and track your progress. |

DIY Training Kits | Practice with real tools and keep materials for future use. |

Train-the-Trainer | Get certified and help others learn, too. |

A good course teaches both rules and hands-on skills. You learn safety steps, how to check the machine, and how to use a lift chart. You also show your skills by using the machine, checking how much it can lift, and lifting loads safely.

DeepKron gives you guides and resources to help you avoid mistakes and use your mini excavator well.

Technique Improvement

You can always get better at lifting. Look at the lift chart before each job. Know how much your machine can lift at different heights. Always put your mini excavator on flat, solid ground. Use stabilizers or the blade for more balance. Lift slowly and keep control. Do not stop or turn quickly. Keep the load close and inside the safe area.

Here are some tips to help you avoid mistakes and stay safe:

Pick the right bucket size for each job.

Make sure the bucket is balanced before lifting.

Plan your path and look for things in the way.

Talk with your team during every lift.

Try a test lift at low speed to check balance.

If you keep learning and practicing, you will avoid most operator mistakes. DeepKron’s team is ready to help you get better and keep your lifting safe.

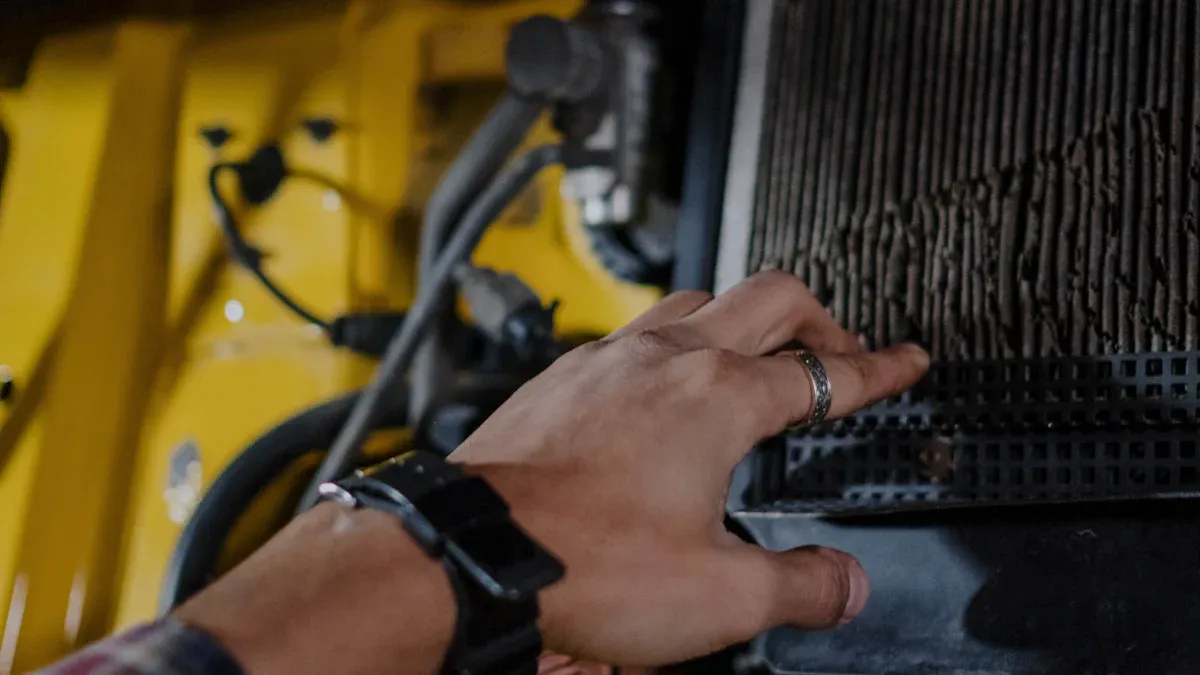

Maintenance Neglect

Skipping maintenance may seem like it saves time, but it can cost a lot. Many mini excavator operators do not notice early warning signs. This causes repairs to be expensive and work to stop. If you skip regular checks, your machine could break down and cost more each year. DeepKron machines are strong, but all equipment needs care to lift safely.

Routine Checks

Checking your mini excavator often helps you find problems early. You should look at the engine, undercarriage, and tracks every day. These steps help your machine work well and make lifting safer. Here is a quick list of what you should do:

Frequency | Maintenance Tasks |

|---|---|

Daily | Visual Inspection, Tracks and Tires, Hydraulic System, Fluid Levels, Cleaning, Lubrication, General Inspection |

Weekly | Filtration, Fasteners, Hydraulic Fluid Replacement |

Monthly | Oil Change and Filter Replacement, Battery Maintenance |

Quarterly | Thorough Inspection, Calibration and Testing |

Annual | Professional Full Inspection |

Always check fluid levels, air filters, and safety features. If you see leaks or worn parts, fix them right away. Skipping these steps is a common mistake for mini excavator maintenance.

Tip: Waiting until something breaks costs more for most operators. Stay ahead by following a schedule and using DeepKron’s service help.

Record Keeping

Good records help you plan and stop problems before they start. You should make a log for each mini excavator. Write down when you do service, how many hours it worked, and what you fixed. Many people use apps or spreadsheets to keep track. This helps you know when to do the next check.

Make a log for each machine.

Use digital tools to track work.

Build a schedule from old records.

Code failures to find patterns.

Plan for parts and technician visits.

If you keep good records, you will not miss checks and your mini excavator will be ready for every lift.

You can make your project faster and save money if you fix mini excavator lift problems early. This also helps keep your team safe. Here are some good things that happen over time:

Benefit | Description |

|---|---|

Improved Project Efficiency | Projects can finish up to 40% faster. |

Reduced Operational Costs | You use 30% less fuel, so you spend less. |

Enhanced Safety | There are fewer accidents and insurance costs go down. |

Better Resource Management | Machines are used more and do not sit unused as much. |

Be safe by wearing safety gear, buckling your seat belt, and keeping the work area clean. Pick DeepKron for equipment you can trust and helpful support.

FAQ

How do you know if your mini excavator is overloaded?

Check the lift chart before you start. If the machine feels unstable or the alarm sounds, stop and reduce the load.

What should you do if you see a hydraulic leak?

Turn off your mini excavator right away. Inspect the hoses and fittings. Call a technician if you cannot fix it yourself.

Does DeepKron offer training for new operators?

Yes! You get access to guides, videos, and support. DeepKron helps you learn safe lifting and proper machine use.