When you choose a mini excavator, match its features to the soil. The soil type changes how your machine works. It also affects how safe your job site is. Look at this table to see how soil changes digging:

Soil Type | Characteristics | Impact on Excavation |

|---|---|---|

Sand | Drains water well, easy to dig | Good for fast digging jobs |

Silt | Drains water okay, holds moisture | Works for trench jobs that need steady ground |

Clay | Thick, sticky, hard to dig | Best for jobs that need no leaks, like landfills |

DeepKron builds small excavators for all kinds of soil.

Key Takeaways

Pick a mini excavator that matches the soil type. Clay needs strong grip and tough buckets. Sand needs wide bases to stay steady.

Pick the best attachments for your work. Rippers break hard ground. Grading buckets make sand flat and smooth.

Check your mini excavator after you use it. Look for any damage, especially after rocky soil jobs. This helps keep it working well.

Mini Excavator for Clay Soils

Challenges in Clay

Working in clay brings its own set of problems. You might notice the ground feels sticky and heavy. Machines can get bogged down or even stuck. Sometimes, the weather makes things worse. Rain turns clay into a slippery mess, which can delay your project or make it unsafe. Take a look at the table below to see what operators often face:

Challenge Type | Description |

|---|---|

Equipment Limitations | Heavy machinery struggles with hardened clay, leading to wear and breakdowns. |

Manual Labor Challenges | Hand digging is labor-intensive; wet clay creates exhausting conditions for workers. |

Weather Dependencies | Excavation is affected by moisture conditions, causing project delays and unpredictability. |

You can see why picking the right equipment matters so much.

Key Features to Consider

When you choose a mini excavator for clay, you want features that help you work smarter, not harder. Here are some things to look for:

Tooth buckets or hydraulic hammers help you break through tough spots, like rocks or tree roots.

Machines with strong bucket breakout force make digging in heavy clay easier.

Versatile attachments let you switch tasks fast, so you do not waste time changing equipment.

You should also match the size of your machine to the job. Think about how deep you need to dig and how much you need to lift. Always check the ground before you start. If you see standing water or the ground feels spongy, be careful. Wet clay can be slippery and dangerous.

Tip: Use the right tools for the job. A tough Rockwheel or a strong bucket can make a big difference in clay.

DeepKron DK16P for Clay

The DeepKron DK16P stands out as a great choice for clay. This mini excavator gives you the power and control you need. Its high-performance hydraulics and reinforced undercarriage help you work through sticky, dense ground without getting stuck. The DK16P also comes with a hydraulic thumb and a dozer blade, which make it easier to handle heavy, wet clay.

Many users love how easy it is to use. One owner said, “I have a small backyard, and this machine has made daily chores so much easier. It’s the right size for tight spots but still has the power for digging and hauling.” Another user shared, “I’ve used it for trenching and moving soil, a little bit for forestry jobs, and it’s handled everything without issues.” These stories show that the DK16P can handle tough clay jobs and save you hours of hard work.

If you want a mini excavator that works well in clay, the DK16P is a smart pick. It is compact, powerful, and built to last.

Note: Always check the soil before you start. Wet clay can clog your tools and make the ground unsafe.

Selection Tips:

Make sure your mini excavator has enough breakout force for heavy clay.

Choose a model with strong traction and a reinforced undercarriage.

Look for attachment options like tooth buckets or hydraulic thumbs.

With the right mini excavator, you can tackle clay with confidence and get the job done faster.

Mini Excavator for Sand and Rocky Soils

Sand: Key Considerations

Working in sand feels different from other jobs. The ground shifts under your machine. You might notice your mini excavator struggles to get traction. Sometimes, the tracks sink or slip, making it hard to move forward. Sand can also cave in around your trench, which means you need to stay alert and use safe digging methods.

Here are some things you should watch out for when working in sand:

Loose sand makes it tough for your mini excavator to grip the ground.

The risk of cave-ins is higher because sand does not hold its shape well.

Standard trench protection, like sloping the sides, may not work. You might need to use shoring or trench shields for safety.

If you want to avoid getting stuck, choose a mini excavator with a wide undercarriage and rubber tracks. These features help spread the weight and keep you moving. Attachments like grading buckets make it easier to level the ground. You can also use rippers to break up packed sand before you dig.

Tip: Always check the stability of your trench walls. In sand, safety comes first!

Rocky: Main Challenges

Rocky ground brings its own set of problems. You might find it hard to dig because rocks slow you down. Sometimes, you need special attachments just to get started. Smaller machines can struggle in rocky soil, so you need to pick the right size and tools.

Common challenges you may face in rocky areas include:

Picking the right auger or bucket for breaking through rocks.

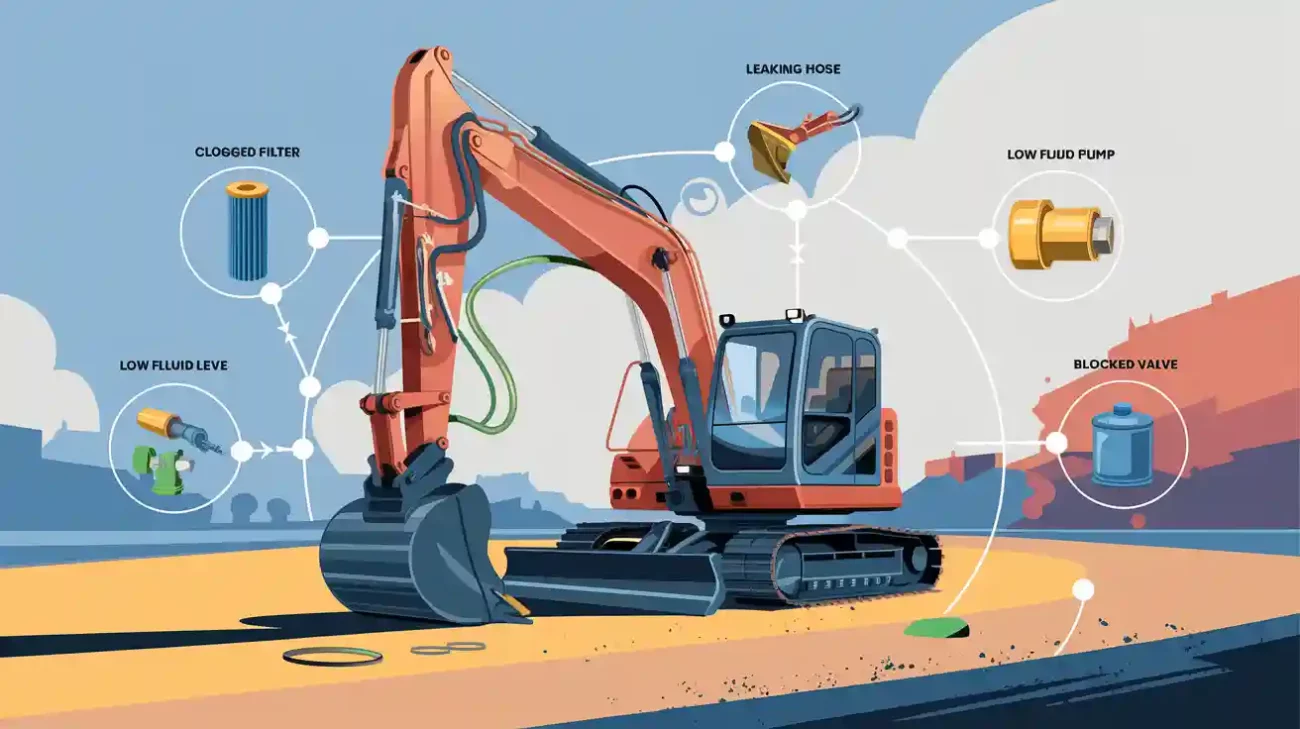

Noticing more wear and tear on your mini excavator, especially around the boom, stick, and bucket.

Checking for cracks, dents, or leaks after each job. Rocks can be tough on your machine.

Watching for uneven tracks or worn bucket teeth, which can affect how well you dig.

You can make your job easier by using a ripper attachment first. This tool breaks up the hard ground and protects your main bucket from damage. After ripping, switch to a trenching bucket to finish the job. This method saves time and keeps your equipment in good shape.

Note: Always inspect your mini excavator after working in rocky soil. Look for signs of damage before you start your next project.

DeepKron DK32 & DK18DA for Sand/Rock

You want a machine that can handle both sand and rocky ground. The DeepKron DK32 and DK18DA models give you that flexibility. Both come with features that help you work in tough conditions and keep your job moving.

Here’s a quick look at what makes these models stand out:

Feature | Description |

|---|---|

Gives you the strength to dig in tough ground. | |

Minimal ground disturbance | Lets you work in sand without making a mess. |

Attachment versatility | Lets you switch tools for different jobs. |

You can use rippers and trenching buckets with these machines. Rippers help you break up rocky soil before you dig. Grading buckets make it easy to level sand. Both models keep ground disturbance low, so you do not have to worry about making big ruts or holes.

Many users trust these machines for tough jobs. One customer said, “I’ve put my Deepkron mini through rain, mud, and gravel. It never quits. It’s like the superhero of my job site!” That kind of reliability matters when you work in changing conditions.

Here are some tips to help you pick the right mini excavator for your next project:

Think about the type of soil at your job site. Sand and rocky ground need different attachments.

Use a ripper to break up hard ground before you start digging.

Choose a grading bucket for leveling, especially if you do landscaping.

For forestry work, try a mulcher or grapple attachment.

Tip: The right attachment can save you time and protect your mini excavator from damage.

With the DeepKron DK32 or DK18DA, you get a machine that works hard in sand and rocky soil. You can switch attachments fast and keep your project on track.

Comparison Table: DeepKron Models

Features by Soil Type

You need the right mini excavator for your job. The table below shows how DeepKron DK16P, DK32, and DK18DA work in clay, sand, and rocky soils. Each model has features that help with different ground types. The excavator bucket is important for every job.

Model | Clay Soils | Sand Soils | Rocky Soils |

|---|---|---|---|

DK16P | Strong traction, reinforced undercarriage, powerful excavator bucket | Wide tracks, stable excavator bucket, easy maneuvering | Good for light rocky work, durable excavator bucket |

DK32 | Stable, but best for lighter clay, versatile excavator bucket | Wide undercarriage, minimal ground disturbance, grading excavator bucket | Handles rocks well, strong excavator bucket, ripper attachment ready |

DK18DA | Compact, works in tight clay spots, flexible excavator bucket | Low ground disturbance, easy transport, grading excavator bucket | Great for rocky soil, powerful excavator bucket, ripper and thumb options |

The excavator bucket helps you dig, lift, and move dirt or rocks. You can change the excavator bucket for grading or trenching jobs. If the ground is hard, use a ripper first, then the excavator bucket.

Quick Recommendations

Here’s an easy way to choose. If you work in clay, pick the DK16P. It has strong traction and a tough excavator bucket for sticky ground. For sand, the DK32 is a good choice. Its wide undercarriage and grading excavator bucket help you move without sinking. If you dig in rocky soil, use the DK18DA. It works well with rocks and lets you add a ripper or thumb for hard digging.

Tip: Check your excavator bucket before you start. A sharp, clean excavator bucket helps you work faster and safer.

DeepKron makes it easy to do excavation jobs. Match your excavator bucket and machine to the soil. You will finish your work with less trouble.

You get the best results when your mini excavator matches your job site. Look at this table to see how digging gets harder at different times:

Stage of Digging | Digging Resistance (kN) | Observations |

|---|---|---|

Initial Cutting | < 80 | It is easy to dig at first. |

Full-Load Lifting | < 80 | It stays easy when you lift a full bucket. |

Cutting & Loading | > 200 | Digging gets much harder as you go deeper. |

Maximum Depth | > 200 | Digging is hardest at the deepest point. This can slow you down. |

Pick a machine that fits your earthmoving needs. You might use a grading bucket or a trenching bucket. DeepKron has good machines for every job. If you have questions about fixing your machine or the warranty, you can call, email, or visit the website. You can also watch videos or read manuals and FAQs to learn more. New machines use electric power and smart tech to make grading safer and easier. Always look at different models, try them out, and check how much it costs to keep them running. DeepKron helps you pick the right grading bucket, trenching bucket, or other tool for your work. You can trust DeepKron for any earthmoving job.

What does the warranty cover?

How do you check if it is easy to service during a demo?

Is it easy and comfortable to use?

Can you reach the engine and hydraulic parts for maintenance?

What are the steps for regular maintenance?

Try out different machines for comfort and how well you can see.

Learn about the cost and needs for maintenance.

DeepKron gives a 12-month or 1,000-hour warranty for used machines.

You can get help by phone, email, or on the website.

Manuals, videos, and FAQs are online to help you use your machine.

Not every attachment works with every mini excavator.

Always check the hydraulic system, weight limit, and coupler before using attachments.

DeepKron says you must match the right attachment to your mini excavator for safety and best results.

Need help picking the right tool? Go to DeepKron’s website and talk to an expert. You will find the best grading bucket, trenching bucket, and attachments for your job.

FAQ

How do you choose the right bucket for clay, sand, or rocky soils?

You want a bucket that matches your soil. Clay needs a strong bucket. Sand works best with a wide bucket. Rocky ground needs a tough bucket.

Can you use the same bucket for trenching in different soil types?

You can use one bucket for trenching, but you get better results with a bucket designed for your soil. Clay, sand, and rocky soils need different bucket shapes.

What attachments help with trenching besides the bucket?

You can add a ripper or grading bucket for trenching. These attachments make trenching easier. You switch the bucket for each job to get the best results.