Farmers must work fast after harvest. The first frost can come quickly. There is not much time to make mistakes. DeepKron DK16P Mini Excavator, DeepKron DK12P Mini Excavator, and DeepKron DK18DA Mini Excavator help teams move fast. These machines go through fields quickly and carefully. If you wait too long to dig trenches, plants can drown. The soil can get too salty. Important nutrients can wash away. Using a mini excavator quickly keeps the soil healthy. It also helps crops grow better in spring.

Why Fast Trenching Matters

Post-Harvest Timing

Farmers know that the days after harvest move quickly. The soil rests, but the clock keeps ticking. Every hour counts. DeepKron mini excavators help teams take action right away. They do not waste time. They move from one field to the next with ease.

Tip: Start trenching as soon as the last crop leaves the field. Early action gives the soil a chance to recover before winter.

Quick trenching helps the soil breathe. Water drains away. Roots from old crops break down better. The ground stays loose and healthy. When spring comes, seeds find a perfect place to grow. Farmers who act fast see stronger plants and better yields. They do not let the season slip away.

Pre-Frost Risks

Frost can arrive without warning. Cold air sweeps in. Wet fields freeze hard. If water sits in the soil, frost locks it in place. This can damage the soil and make spring planting harder.

Here are some risks farmers face if they wait too long:

Water pools in low spots and creates ice patches.

Frozen soil blocks roots and slows new growth.

Salt and nutrients wash away with melting snow.

Heavy equipment gets stuck in muddy, frozen ground.

Note: Fast trenching with DeepKron mini excavators protects the field from these dangers. It keeps the soil ready for the next season.

Farmers who act before frost feel proud. They know their fields will be ready. They see the results in healthy crops and strong harvests. Quick action today leads to success tomorrow.

Field Assessment

Drainage Issues

Every successful field rehab starts with a careful look at the land. Farmers walk their fields and search for signs of poor drainage. They look for standing water, muddy patches, and areas where crops struggled to grow. These spots often show where water collects and does not drain away.

Tip: Use a notebook or a phone to mark trouble spots. Take photos if possible. This helps create a clear plan for trenching.

Farmers know that water can hide under the surface. They check for soft ground and uneven soil. Sometimes, old trenches or ditches have filled in over time. These areas need special attention. DeepKron mini excavators can reach these problem spots with ease. Their compact size lets them move between rows and around obstacles.

A simple checklist helps during assessment:

Look for puddles or wet soil.

Check for yellow or stunted plants.

Find low spots or dips in the field.

Notice any old drainage lines that need repair.

Farmers who spot drainage issues early can fix them before frost. They set their fields up for a healthy spring.

Soil and Debris

Healthy soil means better crops. Before trenching, farmers clear away debris. They remove rocks, leftover stalks, and trash. This step protects the mini excavator and keeps the work smooth.

Note: Clean fields help DeepKron machines work faster and safer.

Farmers test the soil with a shovel. They check if the ground is too wet or packed down. Soft, loose soil makes trenching easier. If the soil feels hard, they may need to break it up first. DeepKron mini excavators handle tough ground, but a little prep work saves time.

A clean, ready field inspires confidence. Farmers know they have done their best. They trust their DeepKron equipment to finish the job strong. Every step brings them closer to a successful season.

Planning Trench Lines

Mapping

Successful drainage starts with a clear plan. Farmers who map their fields before trenching see better results. They use modern tools to make this process easier and more accurate.

RTK GPS data collectors help farmers create detailed maps of their fields. These maps show every dip, slope, and low spot.

AGREM software takes this data and turns it into a custom drainage plan. It can design random tile, pattern tile, or contour-controlled drainage systems.

Advanced machine control systems, like GCS:Pipe and Ditch Assist, guide the mini excavator along the planned trench lines. These tools keep the trench straight and at the right depth.

Some farmers use Punisher GNSS receivers for even more precision. These devices help with both mapping and machine control.

Tip: Accurate mapping helps farmers avoid mistakes. It saves time and makes sure every trench works as planned.

With these tools, farmers can see where water flows and where it pools. They can plan trenches that move water away from problem areas. This careful planning leads to healthier soil and stronger crops in the spring.

Dimensions

The right trench size makes all the difference. DeepKron mini excavators help farmers dig trenches that match the best standards for drainage.

Most experts recommend trenches that are 18 to 24 inches deep and 12 to 18 inches wide. A gentle slope of 1–2% (about 1–2 inches drop for every 10 feet) keeps water moving. This prevents puddles and soggy spots.

Note: Lining the trench with landscape fabric stops soil and debris from clogging the drain. A base layer of washed gravel supports the drain pipe. The pipe should have holes facing down to let water in from below.

Farmers cover the pipe with more gravel and wrap the extra fabric over it. They finish by backfilling with soil. This method keeps the trench working all winter and protects the field for next year’s crops.

Careful planning and the right dimensions set the stage for a successful season. Every step brings the field closer to its best possible condition.

DeepKron Mini Excavator Features

DeepKron is known for new ideas and good quality. They care about making customers happy. You can see these values in every mini excavator they make. Farmers and contractors trust DeepKron machines to work well. This is important when time is short and the weather changes fast. The DK16P, DK12P, and DK18DA models have strong features for field rehab and drainage trenching.

Attachments

Every job needs something different. DeepKron knows that flexibility is important. Each mini excavator can use many attachments. Operators can switch between a digging bucket, hydraulic thumb, dozer blade, or swing boom. This means one machine can do trenching, lifting, grading, and clearing debris. There is no need to wait.

Tip: Use the hydraulic thumb to pick up rocks or roots. This helps keep the trench clean and safe.

DeepKron’s quick hitch system lets you change attachments fast. Operators spend less time getting ready and more time working. Some features, like auxiliary hydraulics and cab enclosures with A/C, add comfort and control. These help even when the weather is tough. Attachments help each mini excavator fit the needs of every field.

Here is a quick look at the technical strengths of DeepKron mini excavators:

Specification Category | Details |

|---|---|

Operating Weight | 3500 lb (1600 kg) |

Max. Dig Depth | 64.96 in (1650 mm) |

Reach at Ground Level | 98.03 in (2490 mm) |

Width with Blade | 38.58 in (980 mm) |

Engine Horsepower | 13.5 hp (9.9 kW) |

Engine Manufacturer | Briggs & Stratton |

Arm Breakout Force | 1461 lbf (6500 N) |

Bucket Breakout Force | 2923 lbf (13000 N) |

Travel Speed | 1.37 mph (2.2 km/hr) |

Hydraulic Thumb | Standard |

Swing Boom | Optional |

Dozer Blade | Standard |

Quick Hitch | Optional |

Reinforced Undercarriage | Standard |

Pilot Control | Standard |

These features give operators what they need to finish trenching before the first frost. DeepKron makes sure every attachment fits right and works well.

Maneuverability

Fields are not always flat or open. Sometimes, operators must work in tight rows or around things in the way. DeepKron mini excavators are great for these jobs. Their small width, just under 39 inches, lets them fit in narrow spaces. Bigger machines cannot go there.

The reinforced undercarriage keeps the machine steady on bumpy ground.

Pilot controls and easy joysticks help operators move with care.

Good hydraulics make every action smooth and easy.

Simple transport lets crews move from one field to another fast.

Note: DeepKron mini excavators help teams finish jobs in places that used to be too hard.

Operators feel sure when using these machines. They know the mini excavator will not get stuck or tip over, even on rough ground. This helps them work faster and get better results. DeepKron’s focus on maneuverability means every field can be ready for spring.

DeepKron’s promise to bring new ideas and keep customers happy shows in every part. The DK16P, DK12P, and DK18DA mini excavators help farmers and contractors do more in less time. With the right attachments and great maneuverability, these machines make field rehab a success.

Trenching Steps

Setup

Getting ready for trenching is very important. DeepKron operators know that good setup saves time and stops problems. They do these things:

Mark the swing area around the mini excavator. This keeps people and cars safe.

Put the machine on flat, steady ground. If the ground is not flat, use pads to stop it from tipping.

Make sure you can see well. Use mirrors, cameras, alarms, and spotters to check blind spots.

Check how much the machine can lift. Do not lift too much, especially on hills.

Look at the trench area. If the trench is deeper than 5 feet, plan for safety systems like sloping or shoring.

Do a risk check. Find out the soil type, look for pipes and wires, check for heavy things on top, watch the weather, and talk about what to do in an emergency.

Check the mini excavator. Look at the chain, sprockets, rollers, and fluids. Test all controls and safety parts.

Put up signs and barriers. Make sure everyone wears the right safety gear.

Never let anyone go into a trench that is not protected.

Tip: Operators who set up the right way work faster and safer. They do not make big mistakes and keep the job moving.

Operation

After setup, operators start trenching. DeepKron mini excavators make this easy and smooth. Operators do these steps:

Start the engine and let it warm up. Listen for strange sounds.

Use the controls to move the boom and bucket. Dig slowly at first to check the soil.

Keep a steady speed. Make the trench straight and at the right depth and slope.

Use the hydraulic thumb to take out rocks or roots. This keeps the trench clean.

Watch for changes in the soil or things in the way. Change how you dig if needed.

Talk to ground workers with radios or hand signals.

Never go under a raised bucket. Lower the boom when not using it.

Put dug-up soil at least 2 feet from the trench edge so it does not fall in.

Safety Alert: Always call utility services before digging. Stay away from marked lines and keep the area neat.

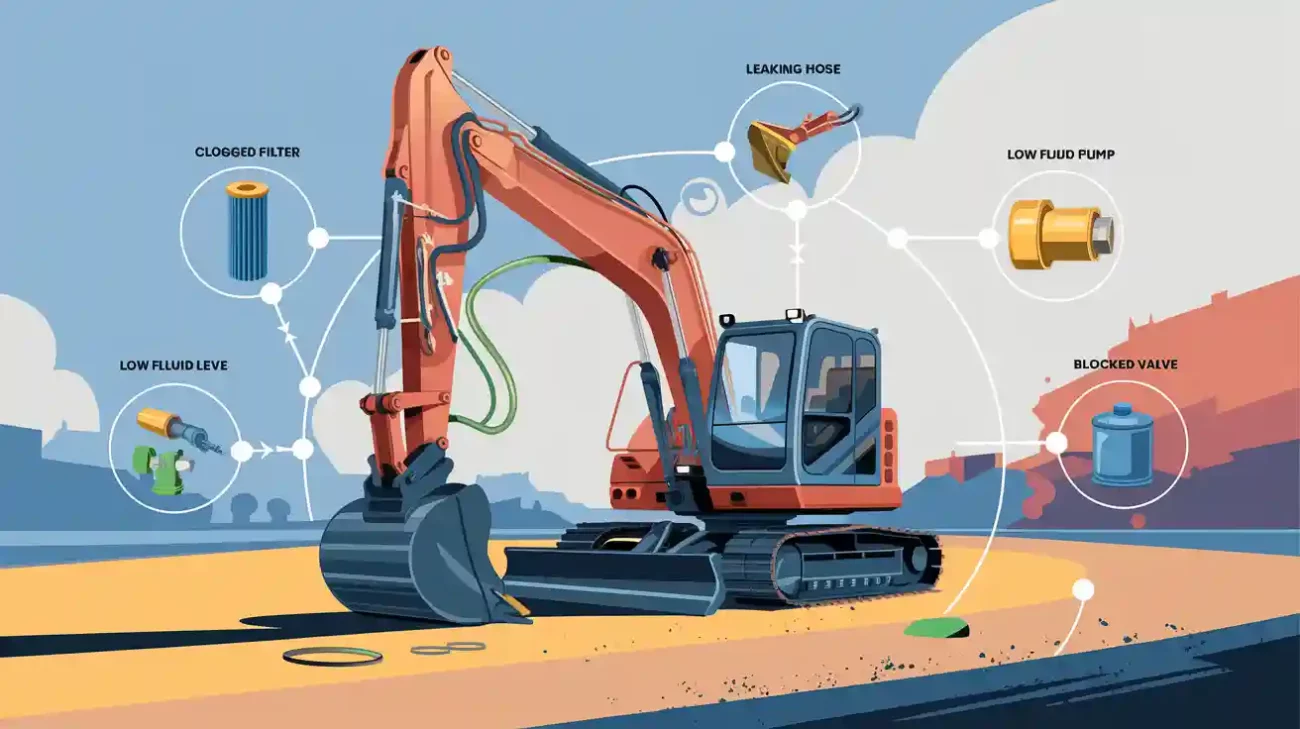

Troubleshooting

Even good operators have problems sometimes. DeepKron mini excavators are strong, but fixing problems fast helps the job. Here is a table of common problems and fixes:

Common Issue | Symptoms | Causes | Solutions |

|---|---|---|---|

Chain and Teeth Wear | Uneven trench, vibration | Worn teeth, loose chain, debris | Replace teeth, adjust chain, clean after use |

Hydraulic Overheating | Loss of power, slow digging | Low fluid, clogged coolers, faulty pump | Check fluid, clean coolers, inspect pump |

Engine Starting Issues | Won’t start, stalls | Weak battery, clogged filter, bad switch | Charge battery, replace filter, test switch |

Improper Chain Tension | Chain slaps or jumps | Chain too loose or tight | Adjust tension before and after use |

Sprocket and Roller Wear | Noises, misalignment | Worn sprockets or rollers | Replace sprockets and rollers together |

Note: Checking the mini excavator every day stops most problems. Operators who do this do not get delayed and finish on time.

Finishing

Finishing the trench the right way helps it work all winter and spring. DeepKron operators do these steps:

Put down crushed stone or gravel in 2–4 inch layers. Press each layer to make a strong, flat base.

Place a drainage pipe wrapped in filter fabric on the base. Make sure the pipe slopes 1–2% toward the outlet.

Cover the pipe with 2–3 inches of crushed stone. Wrap everything in filter fabric before filling the trench.

Fill the trench with gravel or crushed stone in 4–6 inch layers. Press each layer to get rid of empty spaces.

Line up and level the first riser course for a strong platform.

Tip: These steps stop the soil from sinking, frost from lifting, and water from building up. The field stays healthy and ready for spring.

Operators who follow these steps with their mini excavator get good results. They finish on time, protect their fields, and get ready for a great season.

Digging drainage trenches at the right time helps every field. DeepKron mini excavators let teams work fast and get ready for spring. When farmers do this quickly, they get good results that last:

Extra water leaves the soil, so it does not get too wet.

The soil gets more air and is not packed down as much.

Roots grow stronger, and crops give more food.

Fields stay healthy and are ready for each season.

Farmers who follow these steps keep their soil and crops strong for years. If they want more help, they can go to DeepKron’s website to find new ways to do well.