Yes, you can fix weak spots and loose bolts on your mini excavator with easy and cheap ways. If you check your machine often, you can stop big repairs. DeepKron mini excavators work well, but a little care helps a lot. If you use simple tools and do small repairs, you can save a lot of money each year.

Doing regular maintenance can lower repair costs by up to 45%.

Checking your machine every day can stop 85% of problems you can avoid.

You could save $62,000 for each excavator if you have good habits.

Weak Points to Watch

Common Stress Areas

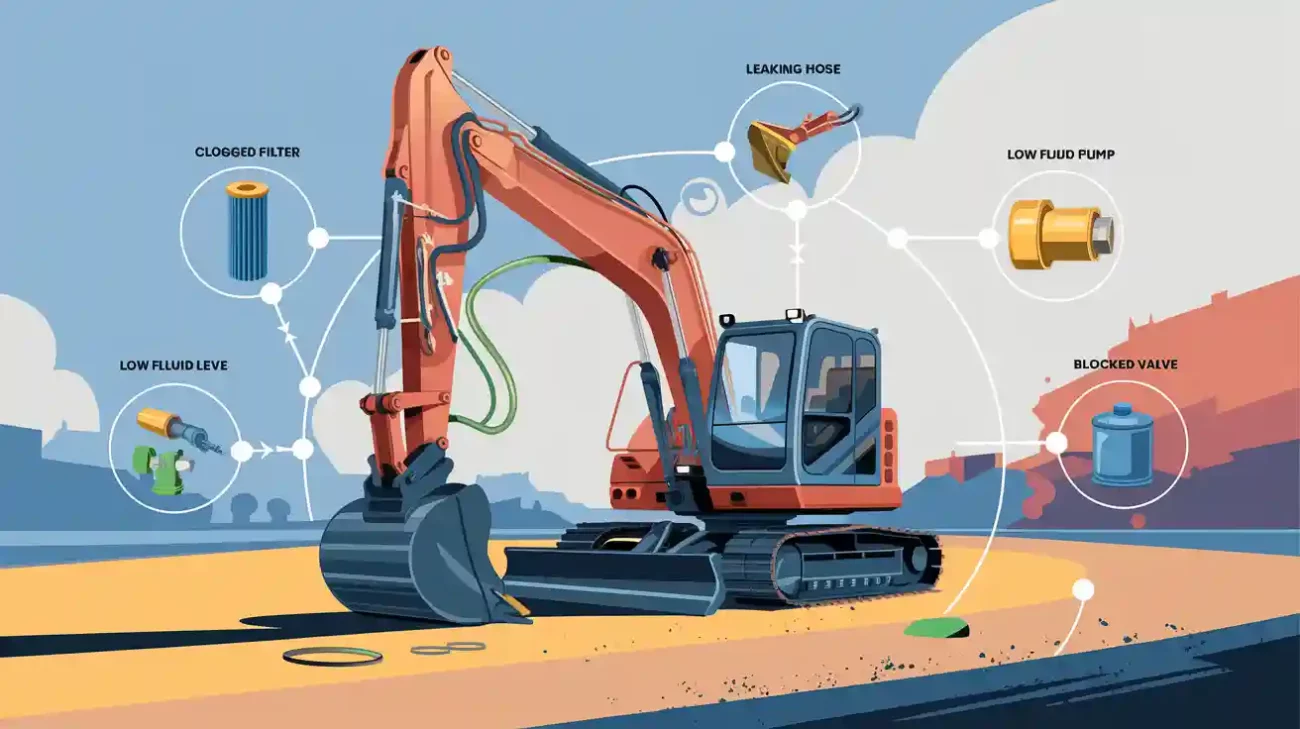

You want your mini excavator to last, so you need to know where problems usually start. The frame and arms take a lot of stress every day. One weak spot is the hydraulic system, especially when the boom or bucket moves while the machine stays still. This can build up pressure in the oil cylinder. If you notice the arms dropping or not holding steady, it might mean there is a leak in the multi-way valve. That’s a sign of a structural issue you should not ignore.

You should also pay close attention to welded joints and lugs. These spots often get tiny cracks because of stress and heavy use. Welded joints, especially in the heat-affected zone, can develop fatigue fractures. These cracks usually start small but can grow fast if you do not catch them early. Loose bolts in these areas can make things worse, so always check them during your routine inspections.

Tip: Focus on welded joints and lugs during your walk-around checks. A quick look can save you from bigger repairs later.

Signs of Wear

You can spot early wear if you know what to look for. Here’s a quick table to help you:

Sign of Wear | Description |

|---|---|

Excessive play | Too much movement in the joint means pins or bushings are worn out. |

Squeaking or grinding | Strange noises tell you the bearings need grease or are already worn. |

Hard to move | If parts feel stiff, they might be under stress or already damaged. |

If you notice any of these signs, act fast. A little attention now keeps your DeepKron mini excavator running strong.

Tools and Materials

Basic Hand Tools

You don’t need fancy equipment to start reinforcing your mini excavator. Most jobs only require a few basic hand tools. Here’s a quick list to keep in your toolbox:

Socket wrench set 🛠️

Adjustable spanner

Screwdrivers (flathead and Phillips)

Torque wrench

Hammer

Pliers

A socket wrench helps you reach bolts in tight spaces. You can use an adjustable spanner for bolts of different sizes. Screwdrivers come in handy for smaller fasteners. A torque wrench lets you tighten bolts to the right level, which is important for DeepKron’s high standards. Pliers and a hammer help with stubborn parts.

Tip: Always check your tools before you start. Clean tools work better and last longer.

Reinforcement Supplies

You need the right supplies to make your repairs strong and reliable. Here’s a table to help you pick what you need:

Supply | Use Case |

|---|---|

Thread locker | Keeps bolts from loosening |

Replacement bolts | Swaps out worn or damaged bolts |

Steel plates | Adds strength to weak spots |

Wear liners | Protects high-friction areas |

Welding rods | Repairs cracks in metal |

Thread locker is great for securing bolts. Replacement bolts keep your machine safe. Steel plates and wear liners add extra protection to stress points. Welding rods help you fix cracks fast.

If you keep these supplies on hand, you can handle most repairs yourself. You’ll save time and keep your DeepKron mini excavator working hard.

Loose Bolts on DeepKron Mini Excavators

How to Check Bolts

Loose bolts can sneak up on you if you don’t pay attention. You want your DeepKron mini excavator to stay safe and strong, so checking bolts should be part of your daily routine. When you walk around your machine before each use, look closely at the boom, bucket, and hydraulic thumb. These areas handle the most stress and are more likely to have loose bolts.

Here’s a simple way to spot trouble:

Inspect all visible bolts and nuts for signs of movement or wear.

Use your hand tools to gently test if any bolts feel loose.

Look for oil leaks near bolt heads, which can mean a bolt is not tight enough.

Check for rust or shiny spots around bolts. These can show that the bolt has been moving.

You should always check the torque of bolts that hold high-stress parts. If you make this a habit, you’ll catch problems early and avoid bigger repairs. DeepKron recommends daily inspections, especially for the hydraulic thumb, to help you find loose bolts, leaks, or worn parts before they get worse.

Tip: A quick walk-around every morning can save you hours of downtime later.

Tightening Techniques

When you find loose bolts, you need to fix them the right way. Don’t just grab a wrench and tighten as hard as you can. You want to follow DeepKron’s quality standards to keep your machine safe.

Start by cleaning the bolt and the area around it. Dirt and grease can stop you from getting a good grip. Use a torque wrench to tighten bolts to the correct level. Each bolt has a recommended torque setting, so check your manual or the DeepKron website for the specs.

Here’s a step-by-step guide:

Remove the bolt if it’s very loose or shows damage.

Clean the threads with a wire brush.

Apply a thread locker like Loctite to the threads. This helps keep bolts tight, even when your excavator vibrates a lot.

Reinstall the bolt and use your torque wrench to tighten it to the right setting.

Double-check your work by testing the bolt with your hand tools.

Thread locker works well because it creates a chemical bond that resists vibration. Lab tests show that chemical locking adhesives keep bolts tight much longer than regular threads. If you use thread locker, you’ll see fewer loose bolts and less downtime.

Note: Always use the right torque specs. Over-tightening can damage parts, while under-tightening can let bolts come loose again.

If you follow these steps, you’ll keep your DeepKron mini excavator running smoothly. You’ll spend less time fixing problems and more time getting work done.

Reinforcing Weak Spots

Welding Plates

You can make your mini excavator stronger by welding reinforcement plates onto areas that get the most stress. If you see cracks or thin spots on the frame or bucket, it’s time to act. Welding a thick steel plate over these weak spots gives your machine extra muscle.

Here’s how you can do it:

Use a 1/2″ thick flat bar for the plate. This size works well for most buckets and arms.

Choose 7018 welding rods. These rods help you get a strong, clean weld that lasts.

Clean the area before you start. Remove rust, paint, and dirt so the weld sticks better.

Weld slowly and evenly. This helps the plate bond well with the original metal.

Many mini excavator owners use 7018 rods for welding plates. This method works for both regular steel and high manganese steel, which you often find in excavator teeth. You don’t need fancy equipment—just a steady hand and the right rods.

Tip: Always wear safety gear when welding. Protect your eyes, hands, and skin from sparks and heat.

DeepKron designs its machines with strong frames, but adding a plate in high-stress spots can give you even more peace of mind. You help your excavator handle tough jobs without worry.

Wear Liners

Wear liners protect the parts of your mini excavator that rub against dirt, rocks, and debris every day. These liners act like armor, taking the hits so your machine doesn’t have to.

The best liners use wear-resistant steel plates. These plates come in different hardness levels, from 400 to 600 HBW. The harder the plate, the better it stands up to scratches and gouges. Some liners even get special treatments, like plasma hardening, to make them last longer in the toughest spots.

You’ll also find hardened alloy steels in the cutting teeth and tips. These steels have extra elements like chromium and vanadium. They go through heat treatment to make them tough and hard, so they can handle big impacts and lots of wear.

If you install wear liners in high-friction areas, you keep your DeepKron mini excavator running longer. You spend less time fixing worn-out parts and more time getting work done.

Note: Check your liners during regular inspections. Replace them before they wear down too much.

Bolt-On Solutions

Sometimes you want a quick fix that doesn’t need welding. Bolt-on solutions make it easy to reinforce your mini excavator. You can add or replace parts using just a wrench.

Here’s a table to help you compare bolt-on and welded options:

Feature | Bolt-On Cutting Edges | Weld-On Cutting Edges |

|---|---|---|

Installation Method | Use bolts, easy to remove | Weld in place, permanent |

Ease of Replacement | Quick and simple | Needs cutting and re-welding |

Strength and Stability | Good, but may loosen over time | Very strong, no risk of loosening |

Best For | Soft or sandy soils | Hard rock or heavy-duty work |

Bolt-on edges and guards work well if you need to swap parts often. You can tighten them if you notice loose bolts, which helps keep everything secure. Welded parts give you more strength for heavy jobs, but they take more effort to replace.

DeepKron always looks for ways to make your work easier and your machine tougher. The company uses smart features like AI predictive maintenance, electric and hybrid power, and onboard weighing. These innovations help you spot problems early, save on repairs, and get more life from your mini excavator.

Pro Tip: If you work in rough conditions, check bolt-on parts often. Tighten any loose bolts right away to avoid bigger issues.

Maintenance Tips

Inspection Schedule

You want your mini excavator to last, so make inspections a habit. Daily checks help you spot problems before they get worse. Look for loose bolts, cracks, and signs of wear. Listen for unusual noises. These sounds can mean something is wrong, like worn bearings or loose parts. If you skip inspections, you might miss early warnings and end up with bigger repairs.

Tip: Stick to the service plan from the manufacturer. This keeps your machine running well and protects your warranty.

A good inspection schedule does more than just prevent breakdowns. It helps your equipment keep its value and work at its best for years.

Lubrication

Grease is your best friend when it comes to mini excavator joints and pivot points. You should hit all the grease points often, especially after heavy use. Proper lubrication does a lot for your machine:

Keeps parts moving smoothly

Stops metal parts from grinding together

Prevents overheating and rust

Cuts down on repair costs and downtime

If you keep up with greasing, you help your excavator last longer and avoid expensive fixes.

Clean Joints

Dirt and debris can sneak into tight spots and cause trouble. After each use, grab a high-pressure washer to blast away mud and grime from joints and undercarriage. Stiff brushes work well for stubborn dirt in small spaces. Cleaning after every job, especially in muddy or icy conditions, keeps your machine in top shape.

Removes mud, grease, and debris from hard-to-reach areas

Stops buildup that can lead to wear and damage

Makes it easier to spot problems during inspections

Note: Clean joints mean fewer surprises and a smoother-running DeepKron mini excavator.

When to Call a Pro

Severe Damage

Sometimes, you find damage that looks too big for a simple fix. Maybe you see a deep crack in the frame or a torn rubber track. In these cases, you should think twice before grabbing your tools. Trying to fix severe damage by yourself can lead to bigger problems. Here are some risks you face with DIY repairs on badly damaged parts:

If you only patch up a problem, the part may not last as long as a new one.

Cracks or tears in rubber tracks are hard to fix at home. Moisture can get inside and cause more trouble.

A quick repair might work for now, but it could fail again soon if you do not fix the real cause.

You want your DeepKron mini excavator to stay safe and strong. If you see major damage, it is smart to call a professional. They have the right tools and know-how to make sure your machine works like new.

DIY vs. Service

You might wonder if you should fix things yourself or hire a pro. Both choices have good points. Let’s look at the differences:

DIY repairs usually cost less. You pay for materials, but you skip labor fees.

Professional service costs more at first because you pay for expert help and labor.

If you learn to do small repairs, you can save money over time and keep your machine in good shape.

A pro can spot hidden problems and fix them right, which helps you avoid bigger bills later.

If you feel unsure or see serious damage, trust a professional. For small fixes, DIY can save you money and teach you new skills. Choose what keeps your DeepKron mini excavator running its best!

You can keep your mini excavator running strong with simple habits:

Grease pivot points

Change oil and fluids

Avoid overloading

Store your machine right

“I’ve put my DeepKron mini through rain, mud, and gravel. It never quits. It’s like the superhero of my job site!”

Even small fixes make a big difference.

FAQ

How often should you check bolts on your mini excavator?

You should check bolts every day before you start work. This habit helps you catch problems early and keeps your machine safe.

Can you use regular bolts for replacements?

No, you should use high-strength bolts that match DeepKron’s specs. Regular bolts may not handle the stress and could fail quickly.

What is the best way to spot a weak spot?

Look for cracks, rust, or shiny metal. If you see movement where parts connect, that’s a sign you need to reinforce the area.