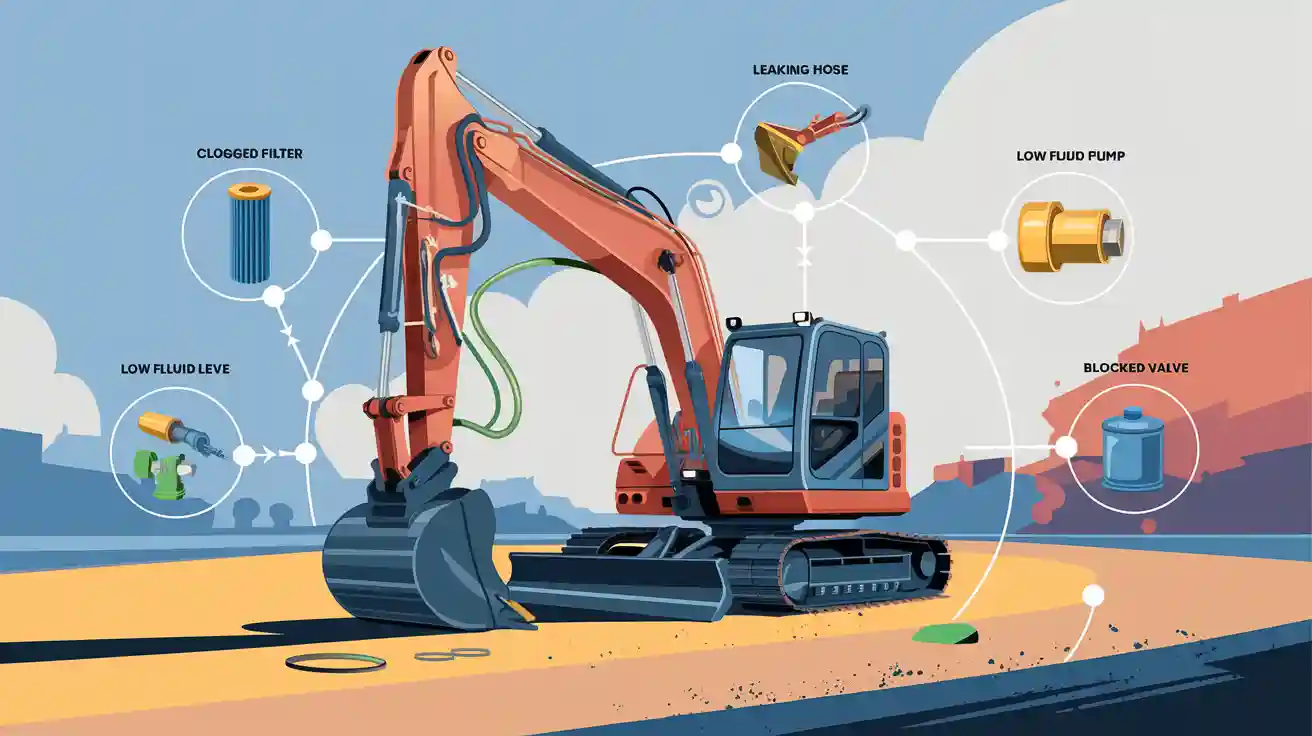

You may notice low hydraulic flow in mini excavators. This happens for five main reasons. These are low hydraulic fluid, clogged filters, dirty fluid, pump problems, and leaks. Hydraulic flow helps your machine stay strong and safe.

DeepKron makes compact machines you can trust. Follow this guide to fix problems fast and keep your equipment running.

Low Hydraulic Fluid

Symptoms

Your mini excavator might feel weak or move slowly. The arm may not lift high or move fast. Sometimes, you hear odd sounds from the hydraulic system. These things can mean low hydraulic flow. If you do not fix these signs, your machine could stop working during a job.

How to Check

Look at the sight glass or dipstick to check fluid. Make sure the machine is on flat ground and turned off. Wipe the dipstick, put it back in, and check the level. Most mini excavators do not have sensors for low fluid. You must check the fluid every day before work. This easy habit helps stop low hydraulic flow and keeps your machine safe.

Solutions

If the fluid is low, add the right hydraulic oil. Always use the oil DeepKron recommends for your machine. Look for leaks around hoses, fittings, and cylinders. Fix leaks as soon as you find them. Doing regular maintenance stops problems early. DeepKron says to check fluid and look for leaks every day. This keeps your mini excavator strong and stops low hydraulic flow.

Tip: Use this table to see why fluid levels drop in mini excavators.

Cause | Description |

|---|---|

Leaks | Hydraulic leaks can make fluid drop a lot and hurt performance. |

Insufficient Maintenance | Not checking often can cause you to miss fluid loss and make the system work badly. |

Absence of Level Sensors | Many mini excavators do not have level sensors, so it is harder to watch fluid levels. |

Clogged Filters

Warning Signs

Your mini excavator might move slower than normal. The arm may not lift up smoothly. You could hear odd noises from the hydraulic system. These things often mean the filters are clogged. When filters get blocked, fluid cannot flow well. This causes low hydraulic flow and can make big problems.

If you do not fix clogged filters, you could break important machine parts.

Clogged filters can cause:

Pressure spikes in the hydraulic system

Damage to the cam in radial piston motors

Freewheeling in hydraulic motors

Bearing failure

Blown seals and fluid leaks

Cracked or blown-off cover plates in the final drive

Inspection Steps

First, turn off your mini excavator and let it cool. Find the hydraulic filter on your machine. Check if there is dirt, debris, or damage. Look at the filter indicator if your machine has one. If the indicator is red or shows high pressure, the filter is probably clogged. You should check filters every month to stop low hydraulic flow.

Step | What to Do |

|---|---|

1 | Turn off and cool machine |

2 | Locate hydraulic filter |

3 | Check for dirt or damage |

4 | Read filter indicator |

Filter Replacement

Change clogged filters with DeepKron-approved filters. These filters help keep your hydraulic system clean and strong. Always use your machine’s manual when changing filters. The right filter stops low hydraulic flow and saves your equipment from expensive repairs.

Tip: Changing filters often keeps your mini excavator safe and working well.

Contaminated Fluid

Effects

If the hydraulic fluid is dirty, your mini excavator can have big issues. Dirt, water, or other things in the fluid make the hydraulic flow drop. Your machine might move slower or lose power. Dirty fluid wears out important parts faster. The system does not work as well. Over time, you will have more breakdowns and pay more for repairs.

Dirty fluid makes hydraulic parts wear out faster.

Bad stuff in the fluid can block or damage small parts, which makes the machine work worse.

If the fluid stays dirty, your machine gets old faster and needs more fixing.

Experts say dirty fluid causes most hydraulic system failures. Most pumps break because the fluid is old or dirty. If you do not check the fluid, you could pay a lot for repairs and lose work time.

Detection

You can find dirty fluid by looking at its color and smell. Clean hydraulic fluid is clear and does not smell strong. If the fluid looks cloudy, dark, or milky, it is probably dirty. Watch for foam or bubbles in the tank. These mean water or air got into the system.

Look for bits or thick stuff in the fluid.

Notice if the fluid color changes.

Smell for anything strange.

Checking the fluid often helps you find problems early and stop low hydraulic flow.

Cleaning Process

To fix dirty fluid, drain it and put in clean, certified hydraulic fluid. DeepKron says to follow these steps for good fluid care:

Only use clean, certified hydraulic fluid.

Change the fluid when the manual says.

Keep up with filter changes.

Check system parts often.

Fix leaks right away.

Store fluid in a clean, dry spot.

Do not mix different hydraulic fluids.

Doing these things keeps your mini excavator safe from low hydraulic flow and expensive repairs.

Pump Issues

Signs

Your mini excavator might feel weak or slow. Sometimes, everything loses power at once. Other times, only some movements are slow. You may hear loud noises from the pump. These noises can sound like whining or rattling. These signs usually mean there is a pump problem.

Here is a table that shows what pump issues look like and what they mean:

Test Result | Likely Issue | Repair Needed |

|---|---|---|

Low pressure (all functions) | Pump wear or leakage | Pump rebuild or replace |

Uneven pressure (some functions) | Valve spool issue | Valve service/replacement |

Intermittent pressure loss | Air in system or seals | Bleeding or seal inspection |

If you see these signs, fix them fast. This helps stop more damage and keeps hydraulic flow strong.

Diagnosis

You can check if the pump is working by measuring pressure and flow. Use pressure gauges to see if the pump makes enough pressure. If the pressure is low, the pump might be worn out or leaking.

You can also check pump efficiency in three ways:

Volumetric efficiency means you compare real flow to rated flow.

Mechanical or hydraulic efficiency means you check the force needed to run the pump.

Overall efficiency means you multiply the two numbers above to see total pump health.

If the numbers are low, the pump may need fixing.

Fixes

First, separate the hydraulic system and put on pressure gauges. Watch the numbers while the machine runs. If the pressure is low, turn off the machine and release the pressure. Take out the pump and look for worn or broken parts. Change any bad parts with DeepKron parts. Clean all the surfaces before putting the pump back. Line up everything as the manual says, then test the pump again.

Checking often and fixing problems quickly keeps your mini excavator safe from low hydraulic flow and big repairs.

Leaks

Visual Clues

You can find leaks by looking for wet spots or puddles. Oil stains on hoses or around cylinders mean fluid is leaking out. Dirt may stick to oily places on your mini excavator. Sometimes, the machine moves slower or feels jerky. These signs usually mean there is a leak causing low hydraulic flow.

Operators who notice weird movements or slowdowns help find leaks early.

Finding Leaks

Check the usual places where leaks happen first. Most leaks come from loose fittings, broken seals, or damaged hydraulic lines. Look at where hoses connect to pumps, valves, and cylinders. Check seals for cracks, swelling, or marks. Use a UV dye to find leaks you cannot see. Pressure tests help you find drops in system pressure. Thermal scans can show hot spots from friction. Fluid tests help you see if leaks caused contamination.

Loose or broken fittings

Bad seals in cylinders and pumps

Damaged hydraulic lines

Ways to find leaks:

Look for leaks

Use leak detection dye

Do a pressure test

Try thermal scanning

Test the fluid

Repair Steps

First, clean the area around the leak. Tighten any loose fittings you find. Change broken seals or hoses with DeepKron-approved parts. Use ultrasonic tools for leaks under high pressure. Watch how much fluid you use to see if leaks come back. After fixing, test the system for normal pressure and movement. Fixing leaks fast keeps your mini excavator working well and saves money. Leaks let bad stuff get in, which wears out parts and raises costs.

Checking for leaks often keeps your machine working well and helps keep hydraulic flow strong.

Control Valve Problems

Malfunction Signs

Your mini excavator may act weird if control valves have trouble. The machine could move slow or not move at all. You might hear strange sounds or see leaks near the valve. Some signs are:

The valve gets stuck and does not move right

The valve stops working and you lose control

If you notice these things, your machine might have low hydraulic flow. Fixing problems fast can stop bigger damage.

Troubleshooting

First, check the control valve for dirt or stuck pieces. Look for leaks around the valve and listen for odd noises. Use a pressure gauge to see if pressure drops when you use the controls. Check the pilot pump and pilot filter too. If these parts break or get blocked, pilot pressure drops and hurts hydraulic flow. Try moving the valve by hand to see if it sticks. Write down any problems before you start repairs.

Tip: Always look at the main overflow valve and main pump for pressure issues. These parts can also make control valve problems.

Solutions

You can fix control valve issues by doing these things:

Change out broken or worn valve parts

Clean or swap pilot filters to fix pilot pressure

Tighten bolts to stop noise and leaks

Reset the valve positioner so it moves right

Keep upstream pressure steady for good hydraulic flow

Use DeepKron parts and follow the manual to keep your mini excavator safe. Checking often and fixing problems quickly saves your machine from low hydraulic flow and costly repairs.

Low Hydraulic Flow Checklist

If you see low hydraulic flow, you need a plan. This checklist helps you find and fix problems fast. It keeps your mini excavator safe and working well.

Causes | Solutions | |

|---|---|---|

Abnormal Noise | Aeration from contaminated fluid | Check and keep fluid clean |

High Fluid Temp | Viscosity drop, heat load increase | Keep fluid level right, check reservoir |

Slow Operation | Loss of flow due to leaks | Look for leaks inside and outside |

Try these steps to fix low hydraulic flow:

Check fluid levels. Make sure fluid is clean and full.

Look at hoses and connections. Check for damage and make sure they are tight.

Watch system pressure. Use gauges to see if pressure is right.

Find leaks. Look for wet spots or stains that show fluid loss.

Use the schematic. Follow the hydraulic system to find trouble spots.

Check system pressures. Make sure settings match the manual.

DeepKron Maintenance Tips

Taking care of your mini excavator keeps it strong and safe.

Use clean hydraulic oil and keep it full.

Check hoses and fittings for leaks often.

Change oil and filters when needed for best results.

Keep hose ends clean to stop dirt from getting in.

Do a full service after every 600 hours of use.

DeepKron gives you expert help and guides. Go to DeepKron’s official website for more tips and support.

If you fix low hydraulic flow fast, your mini excavator works better. You save money because your machine does not stop working. Doing regular maintenance helps your equipment last longer. It also makes accidents less likely.

DeepKron gives you manuals and online guides.

Certified technicians can help you fix problems.

Smart sensors and AI can find issues early.

Innovation | Benefit |

|---|---|

Find problems before they get worse, need fewer repairs | |

Electric/Hybrid Power | Save money and use less energy |