Using deepkron compact machinery right after corn harvest helps protect your grain for next year. When you work fast, you keep your soil healthy. You also get your field ready for another good harvest. The DeepKron DK16P or DeepKron DK500 can help with grain residue and field prep. These machines work quickly and accurately. Studies show the right machinery and attachments can make post-harvest work up to 40% better. Fast field repair also stops frost damage and helps you grow more grain.

Key Takeaways

Work fast after corn harvest to keep soil healthy and get your field ready for the next crop.

Use compact machinery with flotation tires. Drive on the same paths to stop soil from getting packed down. This helps roots stay healthy.

Handle corn residue by leaving some stalks up. Change which parts you remove each year. Plant cover crops to make the soil better.

DeepKron compact machines give you tools that are exact and can do many jobs. They help you chop up residue, make fields flat, and let air into the soil quickly.

Clean your machinery well after harvest. Store it right to stop rust. This makes it last longer and work well next year.

Post-Harvest Prep Importance

Soil Health

It is important to take care of your soil after corn harvest. Healthy soil helps you grow strong grain next year. You should act fast after harvesting. Waiting too long can hurt your soil and lose nutrients. Research says fall prep lets you test soil when it is stable. You can plan how to add nutrients before spring. If you skip this, your corn may not get enough food, and you will get less grain.

Tip: Plant cover crops like cereal rye after harvest. These crops hold the soil in place and stop it from washing away. Radishes and turnips help break up hard soil and help microbes grow. Letting cattle graze on cornfields after harvest adds manure, which feeds the soil.

Heavy combines can cause soil compaction. Compacted soil has less air and water. Roots cannot grow deep, so corn plants stay short. Studies show compacted soil can make plants 21% shorter and cut yield by 19%. Use compact machinery with flotation tires and drive on set paths to stop deep compaction. This keeps your soil loose and ready for next year.

Healthy soil needs:

Good structure

Enough organic matter

Active microbes

Proper moisture

Residue Management

You need to handle residue after every harvest. Corn residue covers the soil, keeps it wet, and feeds microbes. If you take away too much residue, you lose organic matter and risk erosion. The best way is to leave some residue standing and switch which fields you remove it from. Driving combines on the same tracks keeps residue upright and stops compaction.

Here are the best ways to manage residue:

Drive combines on the same tracks to keep residue standing and help soil stay moist.

Graze or bale stalks, but leave some rows to cover the soil.

Add manure if you remove residue to put nutrients back.

Plant cover crops to help break down residue and make soil better.

Use residue managers on planters to clear planting paths but keep residue benefits.

Note: Spreading residue evenly during combining helps avoid wet, cold spots in spring and helps seeds grow better.

Do not till wet soils and use low-pressure tires on combines to lower compaction. If you manage residue well, you lose less at harvest and get your field ready for the next crop.

Residue Management Technique | Benefit for Next Grain Crop |

|---|---|

Controlled traffic with combines | Less compaction, better soil moisture |

Rotating residue removal | Maintains organic matter, reduces erosion |

Adding manure | Replaces nutrients, boosts microbes |

Cover crops | Decomposes residue, improves structure |

Residue managers on planters | Clears path, keeps soil covered |

Acting fast after harvest protects your corn yield and soil health. Good residue management and smart combine use help you avoid losses and get your field ready for strong grain next year.

DeepKron Compact Machinery Benefits

DeepKron is known all over the world for compact machinery. Their harvest equipment is reliable and helps you finish work faster. DeepKron machines use new ideas and are made with good quality. You can count on these machines to do hard jobs. They help keep your field ready for the next season.

Versatility for Corn Fields

You need machines that fit in small spaces and rough ground. DeepKron compact machinery gives you this flexibility.

The machine is about 39 inches wide with the blade. It moves easily between corn stalks.

The hydraulics are set up to help you control every move.

Joystick controls make it easy to use and very accurate.

The undercarriage is strong and works well on rough ground.

You can change attachments for jobs like chopping residue or aerating soil.

You can add features like a swing boom or telescopic undercarriage. This helps you work in any field.

These features help you finish work after harvest quickly. You save time and keep your soil safe for next year.

Attachments and Tools

DeepKron has many attachments to help your farm work better.

Sensors and real-time monitoring help you make fewer mistakes. They also make your work more accurate.

Automated changes, like auto speed and load sensing, keep your work smooth. They also help you feel less tired.

The excavator thumb helps you move rocks or put in fence posts easily.

The small size and simple controls let you work in tight spots.

Smart power and predictive maintenance help your machines last longer.

You can do many jobs at once, so you save time and labor.

Energy-saving features use less fuel and let you work longer.

The strong design means fewer breakdowns and less fixing.

You get more work done with less effort. DeepKron compact machinery helps you finish every job after harvest with confidence.

Farm Efficiency Comparison: Mini Excavator vs. Skid Steer Loader

Task | Preferred Equipment | Reason | Fuel (L/hr) | Labor (hrs) | Attachment Fee ($) |

|---|---|---|---|---|---|

Drainage Ditch Cleaning | Precise digging | 3.2 | 1.5 | 45 | |

Manure Handling | Skid Steer Loader | Fast loading | 2.8 | 1.0 | 35 |

Orchard Pruning | Mini Excavator | Reach high limbs | 3.0 | 1.2 | 40 |

Barn Renovation | Skid Steer Loader | Maneuver indoors | 2.5 | 1.3 | 30 |

Winter Feed Distribution | Skid Steer Loader | Quick transport | 2.6 | 1.1 | 32 |

You can see how picking the right machine makes farm work easier. Mini excavators are best for digging and orchard jobs. Skid steer loaders are faster for moving manure and feed. —choose smart, work easy.

Field Tasks with DeepKron Compact Machinery

Residue Chopping

After harvest, you need to chop corn residue to prepare your field for next year’s grain. You can use deepkron compact machinery with a bush mower or residue chopper attachment. Follow these steps for best results:

Inspect the field for rocks or debris before you start. Remove anything that could damage your combine or mower.

Attach the residue chopper to your machine. Make sure all safety guards are in place.

Adjust the cutting height. Set it just above the soil to leave enough residue for soil cover.

Drive your combine in straight lines across the field. Overlap each pass to avoid missing spots.

Check the chopped residue. It should be evenly spread and small enough to break down quickly.

Tip: Use flotation tires on your combines to reduce soil compaction. This keeps your soil healthy and ready for next year’s harvest.

Safety is important. Always wear gloves and eye protection when working with machinery. Keep children and animals away from the field during chopping.

Field Leveling

Leveling your field after harvest helps you plant grain evenly next season. Deepkron compact machinery with a land leveler or box blade makes this job easy. Here’s how you can do it:

Walk the field and mark low spots or ruts left by combines.

Attach the land leveler to your deepkron compact machinery. Check all connections for safety.

Start at one end of the field. Move slowly and make small adjustment passes over uneven areas.

Use the joystick controls to raise or lower the blade. Fill in holes and smooth out ridges.

Inspect your work. The field should look flat and even, with no deep ruts or bumps.

Safety tips: Always check for hidden obstacles before leveling. Keep your hands clear of moving parts. Stop the machine before making any adjustment.

Level fields help water drain better and make planting easier. You also reduce the risk of combine damage during next year’s harvest.

Soil Aeration

Aerating your soil after harvest is key for strong grain roots. Deepkron compact machinery with an aerator attachment helps you do this quickly. Follow these steps:

Choose a day when the soil is moist but not wet. Dry soil can break up too much, and wet soil can compact more.

Attach the aerator to your machine. Make sure all safety guards are secure.

Drive your combine in a grid pattern across the field. Overlap each pass for full coverage.

Check the soil plugs. They should be deep enough to let air and water reach the roots.

Clean the aerator after use to prevent rust and keep it ready for next harvest.

Scientific studies show that soil compaction from heavy combines limits root growth and reduces grain yield. Compacted soil has less air and water, so roots grow sideways instead of deep. This makes it hard for corn to get enough nutrients, especially potassium. Aerating your soil with deepkron compact machinery helps roots grow deeper and stronger. You get better grain yield, even in dry years.

Tips: Aerate your field every fall after harvest. Rotate your combine paths to avoid compacting the same spots each year. Add potassium fertilizer if your soil test shows low levels.

Safety matters. Always read the operator’s manual before using new attachments. Wear sturdy boots and gloves. Keep bystanders away from moving machinery.

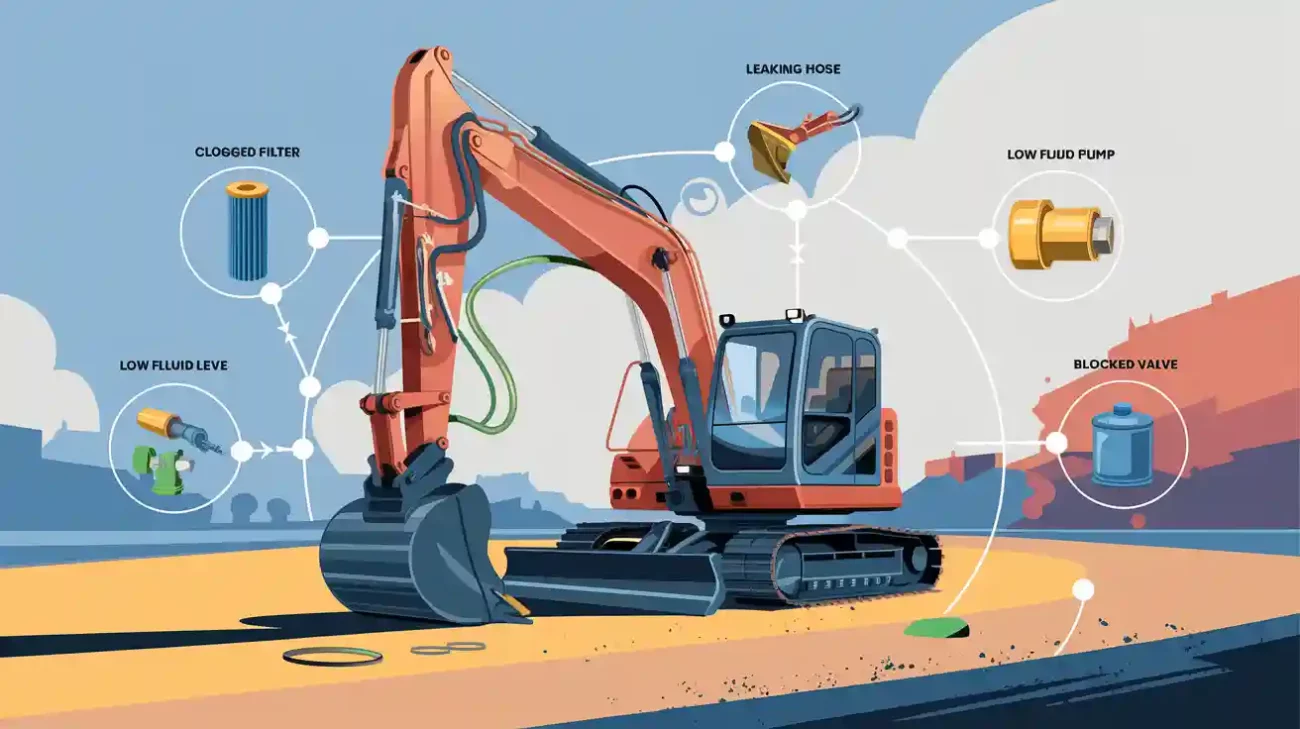

Maintenance and Storage

Cleaning Equipment

You should clean your DeepKron compact machinery after you finish using it for corn harvest. Dirt, crop residue, and water can cause rust if left on your combine. Rust and other problems can happen if you do not clean it. Use a brush or a pressure washer to get rid of mud and debris. Make sure to clean tight spots near the radiator and moving parts. If you see light rust, use sandpaper or a cleaning pad with some WD-40. For more rust, try using Evapo-Rust or Naval Jelly. Always wear gloves and follow safety rules when using chemicals.

Clean your combine often. Wipe metal parts and put on a thin layer of paste wax or rust blocker. This keeps your combine safe from water. Store your combine inside if you can. Use a dehumidifier in the storage area to keep air dry. If you have to store your combine outside, cover it with a tarp and check for water.

Tip: Take off all crop residue and fertilizer salts before storage. These things can make rust form faster and hurt your combine.

Off-Season Storage

Storing your DeepKron machinery the right way keeps it ready for next year. Start by draining or treating the fuel. Change the oil and filters to get rid of water and dirt. Check the tire pressure and fill them to the right level. Take out the battery and keep it in a cool, dry place. Look at the radiator for leaks or bent fins. Fix any broken parts before you store it. Calibrate sensors and GPS so you are ready for next season.

Put your combine in a dry shed with a roof. This keeps it safe from sun and rain, which can crack tires and fade paint. Clean around your combine to keep rodents away. Rodents can chew wires and cause big repairs. Keep a log of all the work you do. This helps you remember combine maintenance and plan for next year.

Safety: Always follow safety rules when working on your combine. Wear gloves, use eye protection, and never work alone.

A study showed that 14% of farm machine failures happen because of bad storage. Good storage and regular checks can help your combine last up to 30% longer. Get your combine checked by a pro before the busy season. This helps you find hidden problems and keeps your combine working well.

Checklist for Off-Season Storage:

Clean all surfaces and take off residue

Drain or treat fuel

Fill tires to the right pressure

Take out and store battery

Calibrate sensors and GPS

Store in a dry, covered place

Keep a maintenance log

Tip: Regular combine care and safe storage protect your machine and help you avoid expensive repairs.

If you work quickly after harvest, you help your next grain crop. DeepKron compact machinery helps you finish all harvest jobs. You use the right combine and equipment for each task. This stops mistakes like forcing your combine or missing maintenance. DeepKron machines help you chop residue, level fields, and aerate soil. You save time and money. You also keep your grain yield high. Their support teams and simple controls make every job safer. To get a strong harvest, use this checklist:

Clean your combine after every harvest.

Store your combine in a dry place.

Check attachments before each harvest.

Use the right combine for each field task.

Contact DeepKron for expert help.

Visit DeepKron’s website to see more harvest equipment and get ready for your next grain harvest.

FAQ

What makes DeepKron compact machinery better for post-harvest field prep?

You get strong, reliable machines that fit tight spaces. DeepKron designs each model for easy use and quick attachment changes. You finish jobs faster and protect your soil for next year’s corn.

How do I choose the right DeepKron attachment for my field task?

Check your field needs first. For residue chopping, use a bush mower. For soil aeration, pick an aerator. The pre-harvest equipment checklist helps you match each job with the best tool.

How often should I clean and maintain my DeepKron machinery?

Clean your machine after every use. Check oil, tires, and moving parts weekly. Store it dry and covered. Regular care keeps your equipment ready and helps it last longer.

Can DeepKron machinery help reduce soil compaction after corn harvest?

Yes. DeepKron compact machines use flotation tires and smart controls. You drive on set paths and avoid heavy loads. This keeps your soil loose and healthy for next year’s crop.

Do I need a pre-harvest corn head for my DeepKron machine?

No. DeepKron compact machinery works best for post-harvest tasks. You use it after you finish harvesting corn, not before. Choose the right attachment for chopping, leveling, or aerating.