AI and machine learning now help the construction industry save money on mini excavator maintenance. Artificial intelligence predicts when heavy equipment will need preventive maintenance. This reduces costly breakdowns and boosts safety. Many construction companies report up to 15% better fuel efficiency and fewer repairs. AI-driven maintenance extends the life of heavy equipment by using data to schedule preventive maintenance at the right time. Heavy equipment in construction gets fewer surprises, and preventive maintenance keeps operations running smoothly.

Key Takeaways

AI-driven maintenance helps predict and prevent mini excavator breakdowns, reducing costly repairs and downtime.

Real-time monitoring with sensors allows early detection of equipment issues, improving safety and machine efficiency.

Automated scheduling ensures timely preventive maintenance, extending equipment life and lowering operational costs.

Using AI improves fuel efficiency by keeping machines running smoothly and reducing fuel waste.

Implementing AI tools requires proper technology, staff training, and data integration to maximize benefits and savings.

Mini Excavator Cost Drivers

Repairs and Downtime

Repairs and downtime create major challenges for the construction industry. When a mini excavator breaks down, projects stop, and crews lose valuable time. Equipment failure from poor maintenance often leads to project delays and higher operational costs. Regular inspections, such as checking track tension and hydraulic oil, help prevent unexpected repairs. Operators who understand the limits of heavy equipment can avoid misuse that causes breakdowns. Keeping detailed maintenance records supports timely servicing and reduces downtime. Neglecting key parts, like the propel drive gearbox, can result in high maintenance costs and lost revenue. Used mini excavators often need more repairs, which increases costs for smaller contractors.

Maintenance and Labor

Maintenance and labor expenses make up a large part of operational costs in construction. Regular servicing, such as oil changes and filter upgrades, keeps heavy equipment running smoothly. The table below shows how these costs add up:

Cost Component | Description | Cost Range / Impact |

|---|---|---|

Maintenance & Repair | Servicing and unexpected repairs | $15,000 – $20,000 annually; major repairs can cost millions |

Operator Training | Hiring and educating workers | $500 – $1,500 per worker |

Downtime Losses | Labor losses and delays from malfunctions | Thousands of dollars per day |

A shortage of skilled operators and technicians in the construction industry can increase operational costs. Advanced mini excavators with sensor systems may require specialized training, which adds to labor expenses.

Fuel and Wear

Fuel and wear also drive up operational costs for mini excavators. Older engines use more fuel, especially when attachments like drills or hammers are in use. Regular maintenance, such as changing air filters and oil, improves fuel efficiency. Skilled operators can reduce fuel use and wear by planning tasks and using the right techniques. The table below highlights key metrics:

Metric | Description | Example / Value |

|---|---|---|

Fuel Consumption Rate | Fuel used per 8-hour day | |

Fuel Cost Per Hour | Based on fuel price | $5.03 per hour |

Replacement Tracks Lifespan | Hours before new tracks are needed | About 2,500 hours |

Electric and hybrid mini excavators offer lower maintenance and fuel costs, making them attractive for construction projects focused on sustainability.

AI in Mini Excavator Maintenance

Artificial intelligence transforms maintenance for mini excavators in construction. AI and machine learning use data from sensors and telematics to predict when machines need preventive maintenance. This approach shifts maintenance from reactive repairs to predictive and preventive actions. Construction companies now rely on predictive analytics, real-time monitoring, and automated scheduling to keep equipment running smoothly and reduce costs.

Predictive Analytics

Predictive analytics uses AI algorithms to analyze large amounts of data from mini excavators. These systems detect patterns and predict when parts will fail. Construction teams can plan preventive maintenance before breakdowns happen. This reduces downtime and saves money.

AI continuously monitors equipment in real-time using sensor data to detect subtle patterns and anomalies, enabling timely interventions.

Machine learning algorithms analyze performance data to predict failures and optimize maintenance schedules.

Digital twin technology creates virtual models of equipment for accurate simulation and prediction of maintenance needs.

AI-driven predictive analytics forecast potential failures, allowing scheduled maintenance rather than reactive repairs.

Benefits include increased equipment lifespan, reduced downtime, cost savings, improved safety, and enhanced operational efficiency.

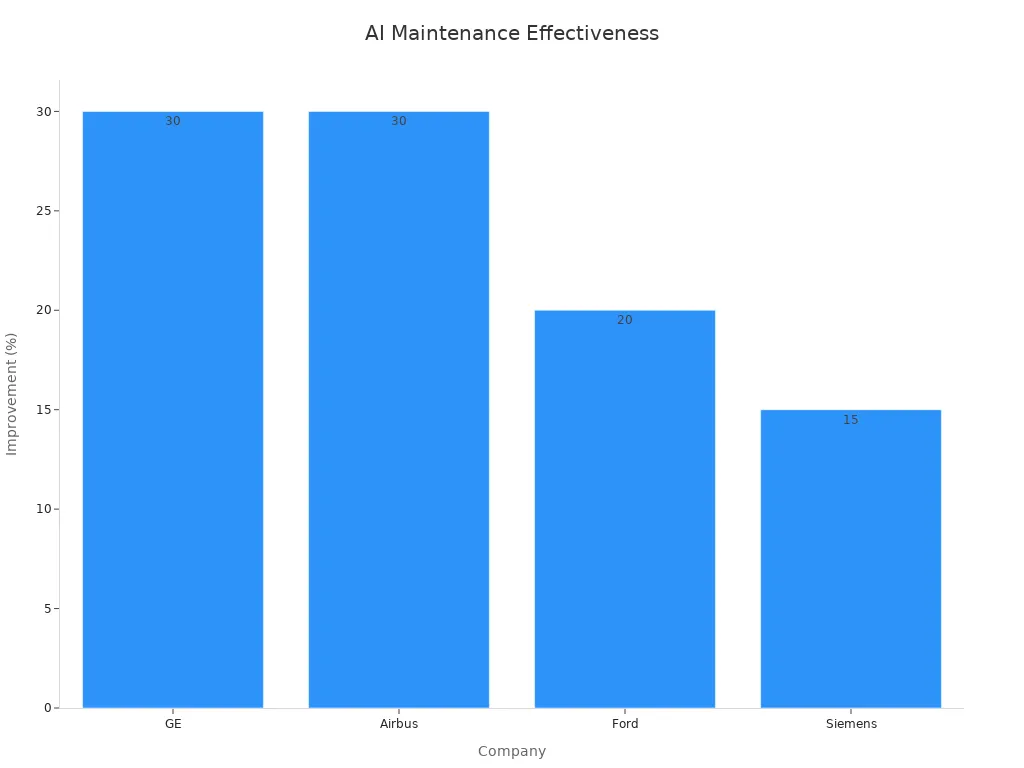

Case studies show the impact of predictive analytics in construction:

Oil quality sensors on excavator hydraulic systems detect early wear, allowing preemptive replacement and avoiding major breakdowns.

Fleet-wide telematics data helps contractors consolidate maintenance scheduling, reducing downtime across multiple machines.

Predictive maintenance leads to 25–30% fewer equipment breakdowns and up to 70% reduction in breakdowns overall.

Evidence Aspect | Description | Impact/Result |

|---|---|---|

AI-based model monitoring vehicle engines with real-time anomaly detection | Achieved 94.7% accuracy, enabling earlier issue detection, lower maintenance costs, improved safety | |

Digital Twin Framework (Advanced Engineering Informatics) | Virtual replicas for real-time health assessment of large structures | Improved anomaly response by 60%, halved inspection times, reduced failure rates by 20% |

Industry Application (Caterpillar) | IoT-based predictive maintenance on excavators and bulldozers | Reduced equipment breakdowns, increased uptime |

Benefits of Predictive Maintenance | AI analyzes sensor data to optimize maintenance schedules, reduce downtime and costs | Extended equipment lifespan, minimized unplanned downtime, cost savings |

Future Prospects | Integration of AI with robotics, 5G, and IoT for enhanced predictive maintenance | Smarter, faster inspections and repairs, improved sustainability and operational efficiency |

Predictive analytics in construction uses big data, IoT, and AI-powered software to optimize maintenance. These tools help companies avoid costly emergency repairs and keep projects on schedule.

Real-Time Monitoring

Real-time monitoring tracks the condition of mini excavators every second. IoT sensors collect data on temperature, vibration, oil quality, and other key factors. AI-enhanced preventive maintenance systems use this data to spot problems early.

Machine monitoring systems provide 24/7 real-time data on machine health and performance. This allows construction managers to address issues before they become serious. Real-time monitoring increases machine utilization and reduces downtime. For example, WessDel’s case study showed 17 extra productive hours per employee each month after using real-time monitoring.

Real-time monitoring enables early detection of equipment issues, reducing troubleshooting time and preventing lengthy downtime.

Key KPIs like downtime ratio, MTTR, MTBF, and OEE are tracked to measure and improve machine performance.

AI-powered predictive maintenance forecasts failures and dynamically adjusts maintenance schedules, preventing unexpected downtime.

Continuous adaptation of maintenance strategies based on real-time data ensures ongoing downtime reduction and operational optimization.

Construction companies use real-time monitoring to improve safety and reliability. Automated alerts notify technicians when preventive maintenance is needed. This proactive approach keeps equipment in top condition and reduces the risk of sudden failures.

Automated Scheduling

Automated scheduling uses AI and data from real-time monitoring to plan preventive maintenance at the best times. Asset tracking software, such as GoCodes, uses QR codes to track equipment location, usage, and maintenance schedules. The system notifies technicians when service is due, ensuring timely preventive maintenance.

Benefit Category | Description |

|---|---|

Preventive tasks are automatically assigned and scheduled, reducing missed inspections and unplanned downtime. | |

Real-time Asset Tracking | Enables tracking of maintenance activities in real-time, improving efficiency and reducing downtime. |

Data-driven Insights | Advanced reporting tools provide insights into equipment performance and failure trends, optimizing maintenance strategies. |

Organized Maintenance Logs | Detailed records of maintenance activities improve recordkeeping and accountability. |

Cost Avoidance | Helps avoid costly emergency repairs by ensuring timely preventive maintenance. |

Equipment Lifespan Extension | Routine maintenance prevents wear and tear, extending the operational life of assets. |

A well-structured maintenance schedule ensures inspections, servicing, and repairs happen at the right intervals. This minimizes unplanned downtime and extends equipment lifespan. Automated operation of maintenance tasks keeps construction projects on budget and on time.

AI-enhanced preventive maintenance, powered by automated scheduling, helps construction companies avoid missed inspections and costly emergency repairs. The use of big data, IoT, and AI-powered software makes maintenance more efficient and reliable.

Cost Savings with AI

Fewer Breakdowns

AI-driven preventive maintenance helps construction companies avoid unexpected equipment failures. Predictive systems use real-time data from sensors to monitor mini excavators. These systems detect early signs of problems, such as changes in vibration or power use. When the system finds an issue, it sends an alert so technicians can fix the problem before a breakdown happens. This approach keeps machines running and reduces downtime.

Scientific studies show that vibration monitoring can spot early signs of mechanical faults. AI systems analyze these patterns and predict failures before they cause breakdowns. Construction teams can then perform preventive maintenance at the right time. This reduces safety risks and keeps projects on schedule. AI-powered predictive analytics in heavy equipment also uses historical and real-time data to forecast potential breakdowns. These alerts help prevent downtime and minimize wear and tear.

A recent study used three years of maintenance records from an excavator fleet. The research showed that optimizing maintenance strategies led to lower direct and indirect costs. Although the study did not mention AI directly, it proved that smarter maintenance planning, which AI can enhance, results in significant cost savings.

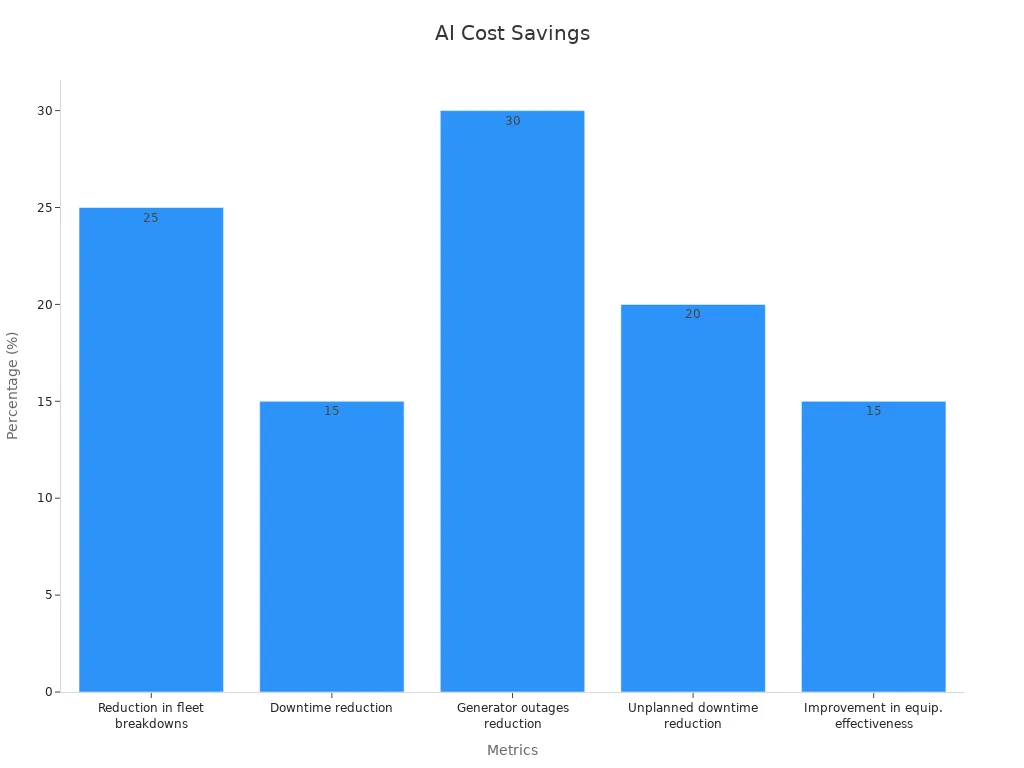

Metric / Example | Quantified Result | Industry / Company |

|---|---|---|

Reduction in fleet breakdowns | General (fleet operations) | |

Unplanned downtime reduction | Up to 50% | General |

Maintenance cost savings | 10-40% | General |

Equipment lifespan extension | Achieved through proactive scheduling | General |

Downtime reduction | 15% | General Motors |

Annual cost savings | $20 million | General Motors |

Generator outages reduction | 30% | Energy providers |

Unplanned downtime reduction | 20% | Volkswagen Group |

Improvement in equipment effectiveness | 15% | Volkswagen Group |

Predictive accuracy for tool wear | Over 90% | Manufacturing sector |

ROI timeframe | Within 18 months | Volkswagen Group |

AI-powered predictive maintenance reduces breakdowns, improves utilisation, and increases profitability for construction companies.

Longer Equipment Life

Preventive maintenance powered by AI extends the life of mini excavators. Predictive systems track the health of each machine and schedule maintenance before parts wear out. This proactive approach prevents small issues from turning into major failures. Construction companies benefit from longer equipment life and fewer expensive repairs.

Real-time monitoring and predictive analytics help teams replace parts only when needed. This reduces unnecessary early replacements and avoids reactive repairs. As a result, machines stay in better condition for longer periods. Companies see higher utilisation rates and improved profitability because their equipment lasts longer.

The Mini Excavator Market Report highlights a trend toward AI-based technologies in construction. Companies use robotics, IoT, and advanced software to improve maintenance. These tools help teams plan preventive maintenance and keep machines in top shape. Longer equipment life means fewer purchases of new machines, which increases profitability.

Note: Proactive maintenance not only extends equipment lifespan but also boosts productivity and enhances efficiency across construction operations.

Better Fuel Efficiency

AI-driven preventive maintenance improves fuel efficiency in mini excavator fleets. Predictive systems monitor engine performance and spot issues that cause higher fuel use. When the system detects a problem, it schedules maintenance to fix it quickly. This keeps engines running smoothly and reduces fuel waste.

Construction companies see better fuel efficiency because machines operate at peak performance. Fewer breakdowns mean less idling and more productive work hours. Predictive maintenance also helps operators use equipment more effectively, which saves fuel and increases profitability.

Data-backed studies show that AI-powered maintenance systems lead to improved operational efficiency and lower fuel consumption. Companies report up to 15% better fuel efficiency after adopting predictive maintenance. These improvements support sustainability goals and reduce overall operating costs.

Tip: Improved fuel efficiency and enhanced efficiency from AI-driven maintenance help construction companies achieve higher profitability and better productivity.

Implementing AI Solutions

Technology Requirements

Adopting AI for preventive maintenance in construction starts with the right technology. Companies often begin with pilot projects, such as using AI-based safety cameras or drones, to test benefits and spot integration issues. They invest in scalable IT infrastructure, including cloud platforms and cybersecurity, to support AI and digital tools. A dedicated budget for digital transformation helps ensure success. Selecting AI tools that fit existing systems reduces resistance and speeds up adoption. Leadership plays a key role by supporting AI and creating roles focused on technology. Clear communication with employees about AI’s role in preventive maintenance builds trust and encourages buy-in.

Note: As construction equipment becomes more autonomous, operators need to develop new technical skills. AI-driven management tools, like digital twins and augmented reality, help monitor equipment and predict preventive maintenance needs.

Integration Steps

Successful integration of AI-driven preventive maintenance follows a step-by-step approach:

Gather reliable data from mini excavators using IoT sensors.

Choose AI tools that match construction workflows, such as drones and design software.

Train staff to use new AI technologies and preventive maintenance tools.

Encourage collaboration and data sharing across teams to improve AI integration.

A construction company improved safety and preventive maintenance by using real-time data from sensors, drones, and wearables. AI models analyzed this data to predict risks and schedule preventive maintenance. Centralized management systems used these insights to send alerts and plan maintenance during low-impact times. Companies using these strategies saw a 30% drop in unplanned downtime and over 20% savings in maintenance costs.

Overcoming Challenges

Implementing AI for preventive maintenance in construction faces several challenges:

Excessive downtime from machine transit and inspection delays.

Inaccurate invoicing when machines are used beyond rental periods.

Siloed data across departments, making asset tracking difficult.

Companies address these issues by connecting telematics data from over 1,000 sensors per machine. They create centralized data lakes using standard protocols to combine information from different sources. Integrating CRM, accounting, and telematics systems gives a complete view of asset location and usage. Geofencing tracks machine presence at sites, linking assets to contracts. Remote diagnostics reduce the need for shop visits, cutting downtime. Automated alerts help teams manage contracts and preventive maintenance more efficiently.

Tip: Centralized data and remote diagnostics increase machine utilization and improve preventive maintenance, leading to higher profitability and better operational efficiency.

AI-driven maintenance transforms mini excavator operations by lowering costs and improving performance. Companies see fewer breakdowns and longer equipment life. Real-time monitoring and predictive analytics help teams act before problems grow. Key benefits include:

Proactive maintenance reduces downtime and keeps machines working.

IoT sensors track equipment, boosting efficiency and safety.

Maintenance costs drop as early detection prevents major repairs.

Productivity rises with fewer interruptions and better planning.

Exploring AI-driven maintenance helps companies stay competitive and manage resources wisely.

FAQ

What is AI-driven maintenance for mini excavators?

AI-driven maintenance uses smart software and sensors to track machine health. The system predicts when parts need service. This helps companies fix problems before breakdowns happen.

How does AI reduce maintenance costs?

AI spots issues early. It schedules repairs before machines break. This reduces emergency fixes and saves money. Companies spend less on repairs and keep projects on track.

Can older mini excavators use AI maintenance tools?

Many older machines can use AI tools if they have sensors or telematics. Companies often add these devices to track data. This upgrade helps older equipment benefit from AI.

Is staff training needed for AI-driven maintenance?

Yes. Workers learn how to use new software and read alerts. Training helps teams understand the system and respond quickly to maintenance needs.

Does AI improve safety on construction sites?

AI improves safety by warning teams about possible failures. Early alerts help prevent accidents. Workers stay safer because machines run better and have fewer sudden problems.