You want your affordable mini excavator to work well and last long. Regular maintenance keeps your DeepKron DK18DA working great. You can save up to 15% on fuel with good habits. If you skip daily checks, repairs could cost up to $20,000 a year. Check fluids every 10 hours to keep your excavator in good shape. Anyone can learn these easy routines, even without experience. Take care of your machine, and it will dig smoothly and give you less trouble.

Key Takeaways

Look at your mini excavator every day for leaks. Check for loose bolts and check fluid levels. This helps stop big problems and keeps it working well. Clean and grease the moving parts each day. This lowers wear, stops rust, and helps your machine last longer. Check the hydraulic system, tracks, and attachments every week. This helps you find small issues before they turn into big repairs. Change oil, filters, and coolant on a set schedule. This keeps your machine strong and stops surprise problems. Write down your maintenance and plan your work. This helps you stay organized, save money, and dig without trouble.

Daily Maintenance

Pre-Operation Checks

Start your day with a quick walk-around. Grab your checklist and become a mini excavator detective. Look for leaks, loose bolts, and anything that seems out of place. Check the DeepKron DK18DA’s swing boom and attachments for any signs of trouble. Standard checklists help you remember every step, so you never miss a thing. Operators who use these lists cut down on mistakes and keep their machines running longer. Training makes a big difference, too. When you know what to look for, you spot problems before they turn into big repairs. Daily pre-operation inspections can prevent about 70% of common breakdowns. That means more digging and less downtime!

Tip: Keep a logbook handy. Write down what you check each day. This helps with warranty claims and keeps your mini excavator maintenance on track.

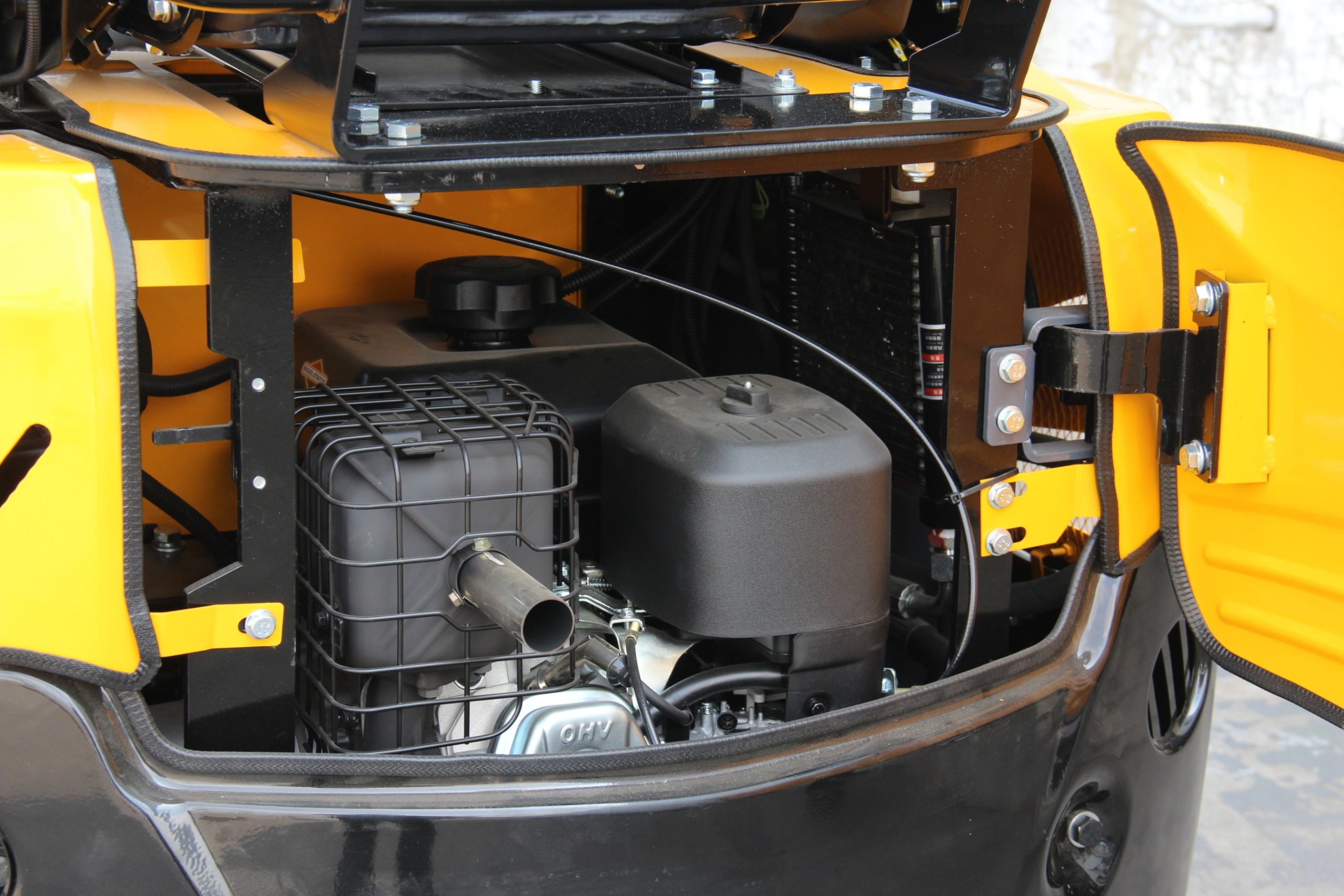

Fluid Levels

Your DeepKron DK18DA loves clean fluids. Before you start, pop the hood and check the engine oil, hydraulic fluid, coolant, and fuel. Low or dirty fluids can cause big headaches. Daily maintenance and inspection of these levels keeps your excavator happy and healthy. Hydraulic oil that looks milky or dark? Time to change it! Coolant too low? Top it up before the engine gets too hot. Proper fluid checks stop system failures and keep your machine working hard.

Engine oil inspections reduce friction and wear.

Hydraulic oil checks avoid system failure.

Fuel checks keep you from running out mid-job.

Cleaning and Lubrication

Dirt loves to hide in every corner of your mini excavator. Don’t let it win! Clean the undercarriage and tracks every day. This stops dirt from wearing down parts and keeps your DK18DA moving smoothly. Air filters need attention, too. A clean filter helps the engine breathe and saves fuel. Grease all the pins and bushings, but don’t go overboard. Too much or too little grease can cause problems. Lubricate pivot points and joints for smooth operation. Regular cleaning and greasing make your machine last longer and save you money on repairs.

Note: Following these daily maintenance tips means less downtime and more digging. Your mini excavator will thank you with years of reliable service.

Weekly Maintenance

You made it through the week! Now your mini excavator deserves a little extra attention. Weekly maintenance keeps your DK18DA running like a champ and helps you dodge those surprise repair bills.

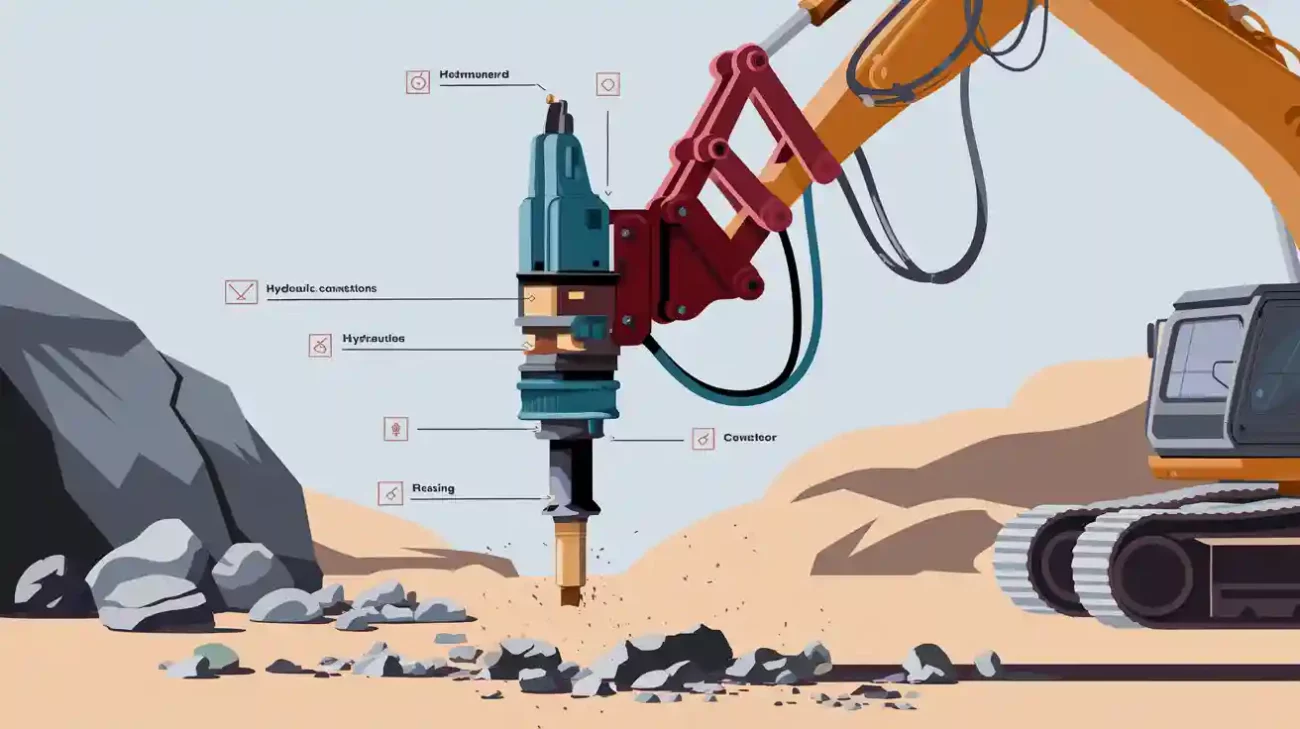

Hydraulic System

Your excavator’s hydraulic system is like its muscles. If you want strong performance, you need to keep those muscles in top shape. Every week, check the hydraulic oil for color and level. If it looks dark or milky, swap it out. Inspect hoses and seals for leaks or cracks. Wipe away any grime so you can spot problems early. The DeepKron DK18DA’s swing boom and hydraulic thumb love a good inspection. Regular checks help you catch small issues before they turn into big ones. Many owners who skip these steps end up with expensive repairs. You don’t want to be that person!

Tip: Keep a simple log of your mini excavator maintenance. This helps you track what you’ve done and spot patterns before trouble starts.

Tracks and Undercarriage

Your tracks and undercarriage take a beating every day. Give them some love each week. Clean out mud, rocks, and debris. Check the track tension—too tight or too loose can cause wear. Look for cuts or missing chunks, especially if you use your excavator on rough ground. The DK18DA’s compact design makes it easy to spot trouble. Regular cleaning and inspection can cut your maintenance costs by up to 20%. That’s more money for snacks!

Practice | Benefit |

|---|---|

Proper Track Tension | Extends track life, prevents breakdowns |

Weekly Cleaning | Stops buildup, reduces wear |

Visual Inspection | Catches damage before it gets expensive |

Bolts and Attachments

Loose bolts love to hide. Don’t let them! Grab your wrench and check every bolt on your excavator, especially around the swing boom and attachments. Tighten anything that wiggles. Inspect attachment points for cracks or wear. The DK18DA’s attachment versatility means you might swap tools often, so double-check those connections. Regular inspections keep your machine safe and ready for action. Miss a loose bolt, and you could face a big repair—or worse, a safety hazard.

Note: A quick weekly check can save you from a $30 problem turning into a $1,200 disaster. Stay sharp and keep your mini excavator maintenance routine strong!

Mini Excavator Maintenance Schedule

You want your mini excavator to run like a champ every day. That’s where a smart maintenance schedule comes in. Think of it as your machine’s personal calendar—never miss a checkup, and you’ll keep your DK18DA digging, lifting, and swinging with ease.

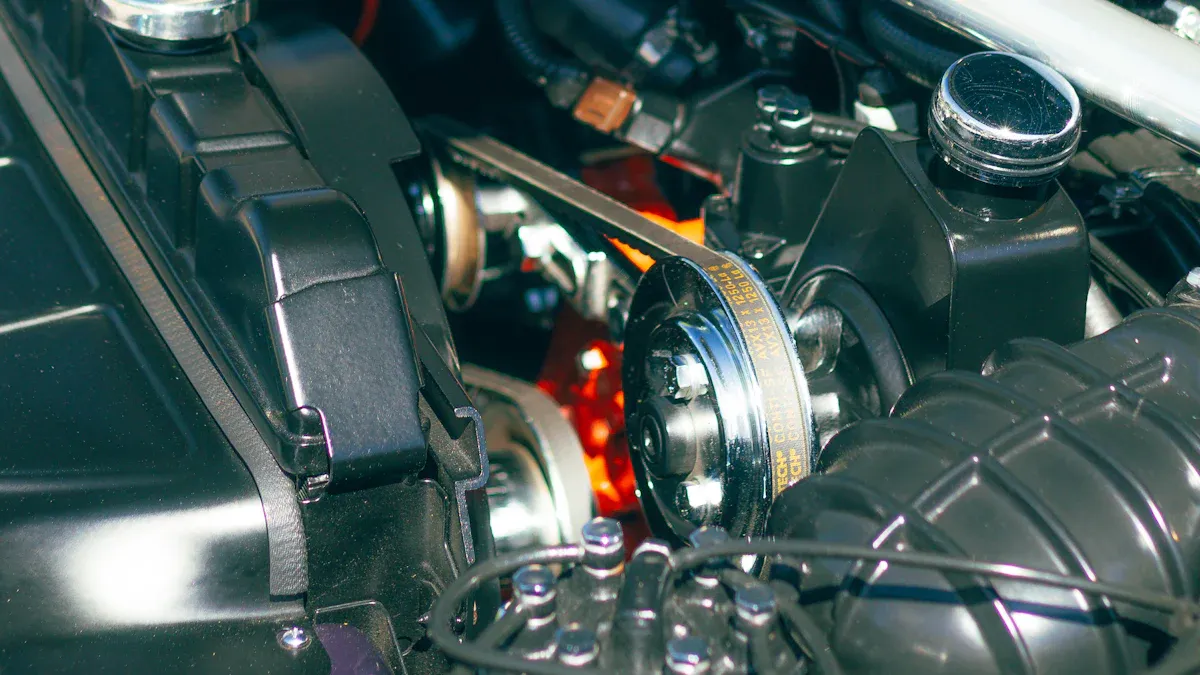

Oil and Filter Changes

Oil is the lifeblood of your excavator. Dirty oil? That’s like running a marathon in muddy boots. You need to change the engine oil and filter on time to keep everything smooth. For most mini excavators, swap out the engine oil and filter every 100 to 500 hours. If you use your DK18DA for tough jobs or lots of attachments, stick to the lower end of that range. Hydraulic oil and filters need attention too. Change the hydraulic oil every 2,000 hours, but if you’re always swapping attachments, do it sooner. Replace the hydraulic oil filter every 1,000 hours. Don’t forget the propel drive gearbox oil—change it every 1,000 hours to keep your machine moving strong.

Here’s a quick look at the recommended intervals:

Maintenance Task | Recommended Interval (hours) | Notes |

|---|---|---|

Engine Oil and Filter | 100-500 | Check more often for heavy use |

Hydraulic Oil Change | 2,000 | Halve if using attachments often |

Hydraulic Oil Filter Change | 1,000 | Halve if using attachments often |

Propel Drive Gearbox Oil Change | 1,000 | Or as per manufacturer instructions |

Tip: For a brand-new DK18DA, do the first oil and hydraulic oil change early. Clean the hydraulic tank, too. This helps flush out any tiny bits left from the factory.

Air and Fuel Systems

Your DK18DA needs to breathe clean air and drink clean fuel. A clogged air filter makes your engine work too hard. Check the air filter every week. Clean it if it’s dusty, and replace it every 500 hours. Fuel filters keep dirt out of your engine. Change the fuel filter every 500 hours or once a year—whichever comes first. If you work in dusty or dirty places, check these parts more often.

Here’s a handy table to keep you on track:

Maintenance Item | Service Interval |

|---|---|

Air Filter Cleaning | Weekly |

Air Filter Replacement | Every 500 hours |

Fuel Filter Replacement | Every 500 hours/Annually |

Note: Clean air and fuel mean fewer breakdowns and more power. Your mini excavator will thank you with smooth starts and strong digging.

Final Drive and Coolant

The final drive is like your excavator’s legs. You want them strong and ready for action. Check the final drive oil every week. Change the oil in the travel gearbox every 1,000 hours. Don’t forget the swing reduction gear case—change its oil every 1,000 hours, too. For coolant, check the level every day you use your DK18DA. Top it up if it’s low. Replace the radiator coolant every 2,000 hours to keep your engine cool and happy.

Here’s a quick checklist for you:

Change travel gearbox and swing reduction gear case oil every 1,000 hours.

Inspect coolant level every 8-10 hours of operation.

Replace radiator coolant every 2,000 hours.

Clean radiator fins and check for leaks or blockages.

Inspect hoses and clamps for cracks or wear.

The DK18DA’s oil pump radiator works hard to keep things cool. Regular maintenance keeps this system running at its best, so your excavator never overheats—even on the hottest days.

🛠️ Pro Tip: Keep the engine compartment clean. Look for leaks, worn belts, or loose hoses. A tidy engine bay means fewer surprises and a longer life for your machine.

A good maintenance schedule saves you money, time, and headaches. Stick to these intervals, and your DK18DA will reward you with years of reliable service. Mini excavator maintenance doesn’t have to be hard—just follow the plan, and you’ll dig with confidence!

Preventing Problems

Wear and Tear

Your excavator works hard every day, so it deserves a little detective work from you. Look for early signs of trouble—worn tracks, loose bolts, or strange noises. If you spot a small crack or a leaky hose, fix it before it grows into a monster repair bill. Operators who check their machines daily see up to 25% fewer breakdowns and save big on repairs. Keep a sharp eye on the undercarriage, idlers, and sprockets. A quick walk-around can help you catch problems early and keep your machine running strong.

Tip: Make inspections part of your routine. A good preventative maintenance program means less downtime and more digging fun!

What to Check | Why It Matters |

|---|---|

Tracks & Tension | Prevents power loss |

Hoses & Seals | Stops leaks and failures |

Sprockets & Rollers | Avoids costly replacements |

Rust and Corrosion

Rust is the sneaky villain of every excavator story. Moisture, mud, and rain love to attack metal parts. Wipe down your machine after a muddy job. Lubricate all the moving parts—especially the hydraulic cylinders and pivot points. A little grease goes a long way to keep rust away. If you spot chipped paint, grab a brush and touch it up. This simple step blocks rust from sneaking in. Regular cleaning and lubrication are your best weapons in the fight against corrosion.

🛡️ Note: Preventative maintenance keeps your excavator looking sharp and working like a champ.

Storage Tips

When your excavator needs a break, give it a safe place to rest. The DK18DA’s compact size makes it easy to tuck away in a garage or shed. Store your machine indoors if you can. If not, cover it with a heavy-duty tarp. Fill the fuel tank for short-term storage, or drain it if you plan to store the machine for months. Check for leaks, pests, or water inside the cab. Clean the tracks and undercarriage before parking. A dry, clean home keeps your excavator ready for action.

Lubricate all joints and cylinders before storage.

Retouch paint on any bare spots.

Inspect your machine every few weeks, even when not in use.

Pro Tip: Keep a maintenance log. It helps you remember what you’ve done and keeps your excavator in top shape for years.

Cost-Effective Mini Hydraulic Excavator Maintenance

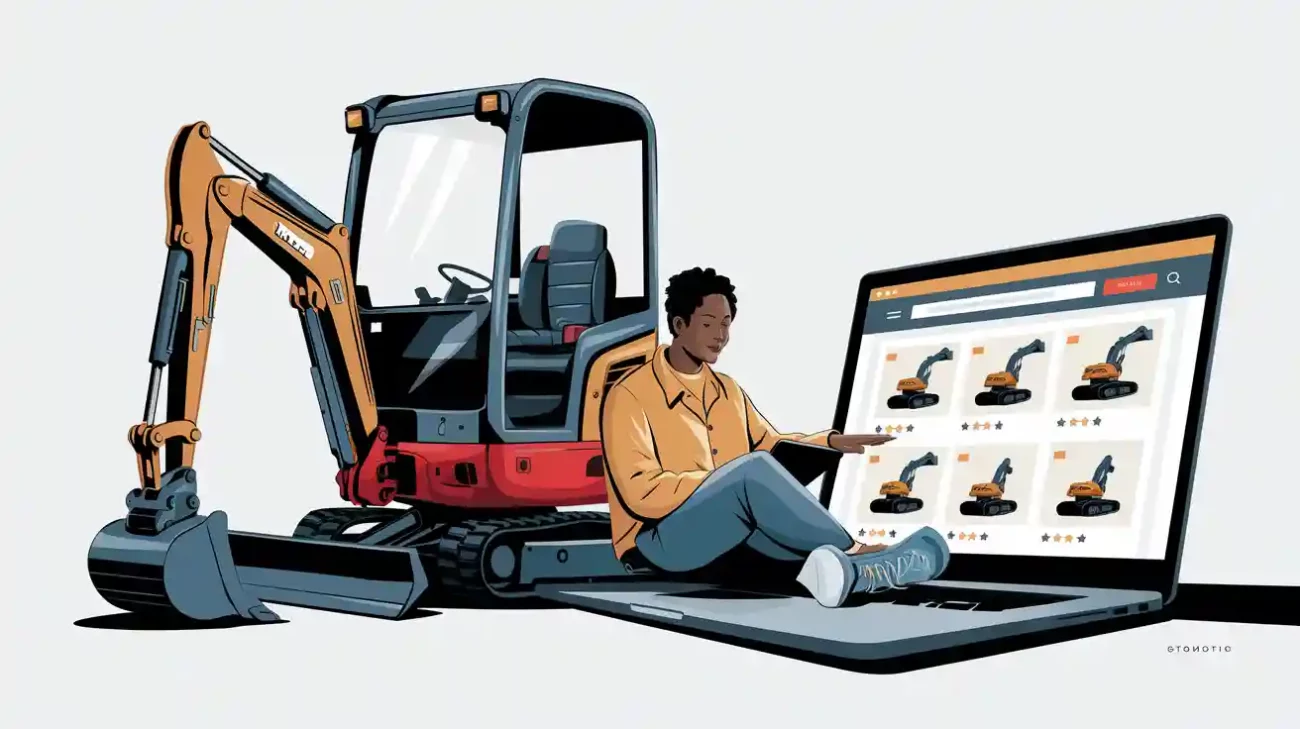

Affordable Parts

You want your affordable mini excavator to work hard and not cost too much. The trick is to make smart choices about parts. You do not always need brand-new parts for every repair. Sometimes, high-quality aftermarket parts fit your DK18DA and cost less money. Always make sure the parts meet the manufacturer’s standards. Buying parts in bulk can help you save even more. Keep extra filters, hoses, and bolts on hand. This way, you will not have to wait for a delivery when you need a quick fix. Using the right parts keeps your affordable mini excavator strong and saves money over time.

DIY vs. Professional

You might ask if you should fix things yourself or call a pro. For easy jobs like changing filters, adding fluids, or tightening bolts, you can do it yourself. Doing your own maintenance helps you learn about your machine. You can also spot problems early. But for hard repairs, like hydraulic leaks or electrical problems, call a professional. Experts have the right tools and skills. They use real parts and can find hidden problems before they get worse. Many owners work with a trusted service provider for regular checkups. Doing some jobs yourself and some with a pro keeps your affordable mini excavator in great shape.

🛠️ Tip: Training helps you and your team stay ready. You will find problems early and avoid big repair bills.

Maintenance Planning

A good maintenance schedule is very important. Make a plan with daily, weekly, and monthly tasks. For example, check and add fluids every 10 hours. Adjust track tension every 50 hours. Change engine oil every 500 hours. Use a checklist for each shift—before, during, and after you work. Write down every maintenance task in a logbook. This helps you keep track of your mini hydraulic excavator maintenance. You will know when you need new parts or service. People who follow a schedule have fewer breakdowns and longer machine life. Your DK18DA will work well for many years!

Task | Frequency | Parts to Check/Replace |

|---|---|---|

Fluid Levels | Every 10 hrs | Oil, coolant, hydraulic |

Track Tension | Every 50 hrs | Tracks, bolts |

Air Filter | Weekly | Air filter |

Engine Oil/Filter | 500 hrs | Oil, filter |

📅 Note: A good maintenance schedule keeps your affordable mini excavator ready for any job. Plan ahead so you never miss a task!

You now know how to keep your mini excavator working well! The DeepKron DK18DA needs daily checks and clean fluids. Give it some care, and it will last longer. Regular maintenance saves you money and keeps your machine ready.

Look at fluids and bolts each day.

Clean and grease all the moving parts.

Follow your maintenance schedule every time.

🏆 Begin your routine now. Take care of your machine and enjoy easy digging every day!

FAQ

How often should you grease your mini excavator?

You should grease all the moving parts every day you use your DK18DA. Grease keeps things smooth and stops squeaks. Your machine will thank you with less wear and more digging power!

What happens if you skip daily checks?

Skipping daily checks is like forgetting to brush your teeth. Problems sneak up fast! You might face leaks, breakdowns, or even a big repair bill. Stay sharp—check your machine every day.

Can you use car engine oil in your DK18DA?

Nope! Your DK18DA needs special engine oil made for diesel engines. Car oil will not protect your excavator. Always use the oil your manual recommends. Your engine will run better and last longer.

How do you know when to replace the air filter?

Look for dust, dirt, or a warning light on your dash. If your engine sounds tired or loses power, check the air filter. Clean it weekly and swap it out every 500 hours for best results.

What is the best way to store your mini excavator?

Park your DK18DA indoors if you can. Cover it with a tarp if you must leave it outside. Clean the tracks, fill the tank, and grease all joints. Your machine will stay ready for action!