If you want your mini excavator to work well in winter, you must take care of the hydraulic system often. Using the right fluid and checking for leaks helps stop problems in cold weather. DeepKron is a trusted brand for strong compact machines.

Good maintenance makes your machine work better and last longer.

Checking your machine often and using the right fluid keeps it safe.

DeepKron’s warranty only works if you use it right and use real parts.

Key Takeaways

Check hydraulic fluid levels often to stop thickening. This helps your machine work well in cold weather. Make sure the fluid is clean and not dirty.

Use winter-grade hydraulic fluid to keep your mini excavator safe from freezing. This helps your machine work its best.

Look at seals and connections often to find leaks early. This can help you avoid expensive repairs later.

Winter Risks for Mini Excavators

Hydraulic System Challenges

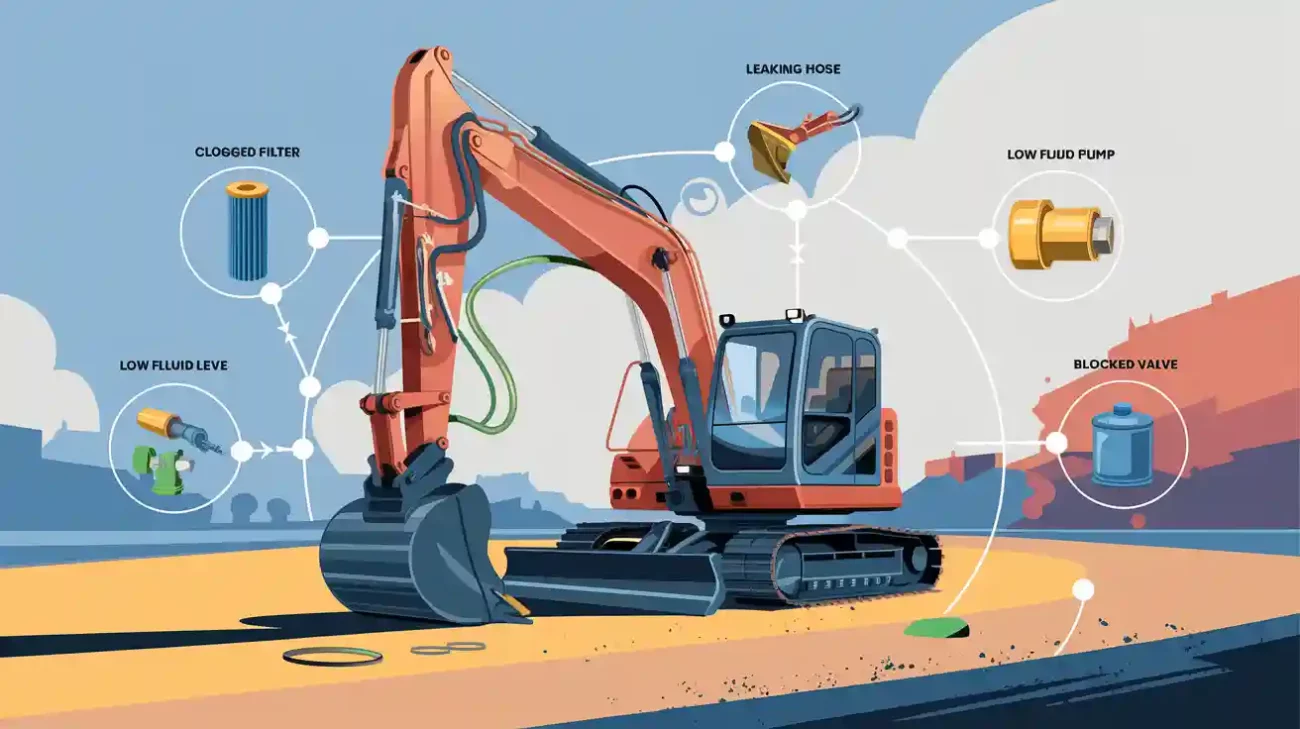

Winter brings new problems for your mini excavator. Cold weather makes hydraulic systems work harder. Hydraulic fluid gets thick and moves slowly. Pumps and motors can have trouble working. Rubber parts may crack or leak in freezing weather. If you start the machine cold, you can hurt important parts.

Here are the most common winter risks for hydraulic systems:

Risk Factor | Description |

|---|---|

Cold makes hydraulic fluid thick. Thick fluid is hard to pump. Check viscosity often. Change or warm fluid when needed. | |

Seal and Connection Vulnerabilities | Cold makes materials shrink at different speeds. Seals, gaskets, and connections can leak. Inspect these parts to stop fluid loss. |

Winter Startup Protocols | Starting hydraulic systems in cold needs extra care. Check fluid levels first. Slowly add load as parts warm up. |

Watch out for these risks so your hydraulic systems work all winter.

Importance of Maintenance

Regular maintenance protects hydraulic systems from winter damage. Cold weather makes oil thicker. Thick oil can slow down your machine. Cavitation can happen if fluid is too thick. This can break the system. Skipping maintenance can cause permanent damage.

Follow these steps to help your machine:

Check hydraulic fluid often in winter.

Look for leaks in seals and connections.

Warm up hydraulic systems before heavy work.

Use hydraulic fluid made for winter.

Tip: Regular checks and the right fluid help hydraulic systems last longer and work better in winter.

Hydraulic Fluid Selection

Choosing the Right Fluid

When winter comes, you must choose the right hydraulic fluid. Cold weather makes regular fluid thick and slow. Thick fluid can hurt your mini excavator’s hydraulic system. Always use winter-grade oil or hydraulic fluid with the right thickness for cold days. Look for fluid that protects against freezing and keeps your engine safe. These features help your fluid move and protect important parts.

DeepKron DK16P, DK12P, and DK18DA mini excavators need good hydraulic fluids. These machines work best with fluid that flows well in cold weather. Using the wrong fluid can damage the engine, pumps, and hoses. The right coolant and hydraulic fluid help your excavator start faster and run smoother.

Hydraulic fluid can harm the environment if it spills. This is a big problem for machines working near water or on farms.

Checking Fluid Quality

Check your hydraulic fluid often in winter. Look at the color and thickness. If the fluid looks milky or dark, change it. Make sure the coolant is clean and filled to the right level. Old or dirty fluid can freeze or block the system. Always use fresh fluids and oils that fit your machine. Good fluid keeps your engine safe and helps your mini excavator last longer.

Regular Maintenance Tips

Leak Inspection

You want your mini excavator to work well in winter. Start by checking for leaks often. Cold weather can make seals get smaller and hoses break. If you do not fix leaks, you can lose hydraulic fluid. This can make your system work badly.

Here are easy ways to find leaks in winter:

Method | Description |

|---|---|

Ultrasonic Detection | Use sound waves to find leaks inside the system. This helps you find leaks you cannot see. |

Black Light Sensitive Dyes | Put a special dye in the hydraulic fluid. Shine a black light and look for glowing spots. These show where leaks are. |

Follow steps to check hoses, seals, and connections. Do this often, especially when it is cold. |

Check fluids, oils, and filters before you put your excavator away. If you find leaks, fix them fast. Change broken hoses and tighten loose connections. This keeps your hydraulic system strong. It helps you avoid big repair bills.

Tip: Check for leaks every day. This helps you find problems early and keeps your system working well.

Fluid Level Monitoring

You need to check fluid levels each time you use your excavator. Cold weather can change how fluids move. This can hurt how your system works. If fluid gets low or dirty, your engine and hydraulic system can have problems.

Here is a simple list for regular maintenance:

Change hydraulic fluids, fuel, and air filters if needed.

Add fuel stabilizer to the tank. Run the engine to spread it.

Use anti-gel in diesel fuel if it is very cold.

Drain old hydraulic fluid and use winter-grade fluid to stop freezing.

Look at hydraulic lines for damage. Make sure connections are tight.

Check that your block heater works. This keeps fluids warm and protects your system.

Water in the system is a big problem in winter. It can cause rust, sludge, and even pump damage. This makes lubrication worse and can cost a lot to fix. Look for milky or dark fluid and change it if you see it. Clean fluids help your excavator last longer and work better.

Note: Doing regular maintenance and checking every day keeps your system clean. It helps your mini excavator stay ready for winter work.

Hydraulic System Care in Cold Weather

Insulate Components

You want your mini excavator to work well in cold. Wrapping hydraulic parts with insulation helps your machine run strong. Use thermal blankets or foam wraps on hoses and cylinders. This stops freezing and keeps fluid moving. It also helps prevent damage from ice and cold snaps.

Look for cracks or leaks in hoses and cylinders first.

Cover exposed hydraulic lines with thermal blankets or foam wraps.

Make sure insulation fits tight but does not block the lines.

Insulation keeps hydraulic fluid at a better temperature. Your machine moves smoother and breaks down less. Block heaters or circulating heaters keep fluid warm in rough weather. Your DeepKron mini excavator stays ready for work and does not slow down in winter.

Tip: Insulating hydraulic parts helps winterize your machine and keeps it working well all season.

Pre-Heat Hydraulic Parts

Cold weather makes hydraulic fluid thick and slow. You should pre-heat the hydraulic system before working. This helps fluid flow better and protects pumps and motors. Use block heaters, circulating heaters, or thermal blankets to warm hydraulic parts.

Turn on the block heater at least 30 minutes before starting.

Use a circulating heater to keep fluid moving inside.

Warm up the excavator slowly. Let fluid reach a safe temperature before using full power.

Pre-heating stops sudden shocks to the system. Your machine works better and important parts last longer. It starts faster and runs smoother, even on cold mornings.

Note: Always depressurize the hydraulic system before storing your excavator for winter. This stops leaks and lowers stress on hoses and seals. Your system stays safe and ready for the next job.

If you follow these steps, your DeepKron mini excavator will work well in cold weather. You protect your machine and keep it reliable all winter.

Storage and Protection

Proper Storage Practices

You want your mini excavator safe in winter. First, get it ready for storage. Clean the machine well. Take off all dirt and mud. Check for leaks or damage in the hydraulic system. Fix any problems before storing. Drain old fluids and put in fresh ones. Use winter-grade hydraulic fluid. Charge the battery. Disconnect it if you will store the machine for a long time. Lubricate moving parts so they do not rust.

Here is an easy checklist for winter storage:

Clean the mini excavator inside and outside.

Look for and fix hydraulic leaks.

Drain fluids and refill with new ones.

Charge and disconnect the battery.

Lubricate all joints and moving parts.

Tip: Getting your machine ready before storage helps it start quickly when winter is over.

Covering and Sheltering

You need to keep your mini excavator safe from snow and ice. Store it in a dry place with a roof. Use a shed or garage if you can. If you must keep it outside, use a strong tarp. Make sure the cover fits tight and keeps water out. Block heaters help keep fluids warm in winter. Put your machine on wood or concrete to keep it off wet ground.

Here is a table to help you pick the best storage:

Storage Option | Protection Level | Notes |

|---|---|---|

Indoor Garage/Shed | High | Best for winter storage |

Heavy-Duty Tarp | Medium | Use if indoor storage is not possible |

Open Ground | Low | Not recommended for winter storage |

Note: Check your mini excavator often during winter. Look for leaks, rust, or damage. Quick checks help you stop big problems later.

Operator Training

Winter Best Practices

You want your mini excavator to run smoothly in winter. Operator training makes a big difference. When you know what to do, you keep your excavator safe and ready for work. Here are some best practices you should follow:

Choose hydraulic fluid made for cold weather. This stops fluid from getting thick and slow.

Check fluid levels and quality every day. Look for leaks and make sure the fluid is clean.

Insulate hoses and use heaters to keep parts warm. This helps your machine start faster.

Do regular maintenance. Look for worn parts and fix them before they break.

Clean your machine often. Dirt and ice can block moving parts.

Store your excavator in a dry place. Drain old fluid and refill with winter-grade fluid.

Learn about cold-weather care. Training helps you spot problems early.

Tip: When you follow these steps, you protect your hydraulic system and avoid costly repairs.

DeepKron Support Resources

You do not have to figure out winter care alone. DeepKron offers support and resources for operators. You can find guides, videos, and manuals on the DeepKron website. These tools show you how to care for your mini excavator in cold weather. If you have questions, DeepKron’s customer service team can help. You get advice on maintenance, fluid selection, and troubleshooting. Training materials help you learn new skills and keep your excavator working all season.

Note: Visit DeepKron’s official website for more tips and support. You get expert help when you need it most.

You can get your mini excavator ready for winter by doing some easy things.

Warm up the hydraulic system before you start working in cold.

Keep your excavator inside and look for leaks or cracks often.

Use oils that flow easily and good fluids for better care.

Check hoses, grease spots, and the battery a lot.

Description | |

|---|---|

Battery Care | Keep the battery in a warm place so it does not freeze. |

Track Tension | Look at track tension and fix it to help it last longer. |

Grease Points | Put grease on pins and bushings every day. |

Gearbox Maintenance | Change the oil when the manual says to do it. |

Fuel and Additives | Add anti-gel to fuel when it is cold outside. |

Oils and Coolants | Use oils that are thin for winter weather. |

These steps help your machine work well and last longer. If you want more help, look at DeepKron’s guides and resources.

FAQ

How often should you check hydraulic fluid in winter?

Check hydraulic fluid every day before you use your mini excavator. Cold weather can make fluid levels change quickly.

What type of hydraulic fluid works best for cold weather?

Choose winter-grade hydraulic fluid with low viscosity. This helps your mini excavator work better and keeps parts safe from freezing.

Can you use regular engine oil in the hydraulic system?

Do not use regular engine oil. Only use hydraulic fluid made for your mini excavator so you do not damage it.