You may get upset when your mini excavator has problems, but others do too. DeepKron knows a good mini machine matters a lot. Many people pick DeepKron for their mini jobs because:

DeepKron mini excavators start fast and work well all day.

The engine and fuel systems are simple to take care of.

Before you ask for help, get your operator’s manual and look at DeepKron support. You can fix many mini problems by yourself.

Key Takeaways

Always look over your mini excavator before you use it. Quick checks can stop many usual problems.

Grease your mini excavator every day. This easy step helps parts move well and saves money on repairs.

If your excavator does not start, look at the battery and safety switches first. These are often the fastest things to fix.

Common Mini Excavator Problems

Mini excavators do tough jobs every day. Sometimes, you face problems that slow you down. Let’s talk about the most common issues and how to spot them early.

Tip: Check your machine before you use it. Many problems can be stopped with a quick look and reading your operator’s manual.

Here is a table with the most reported mini excavator problems:

Problem Type | Description |

|---|---|

Hydraulic Issues | Leaks in the hydraulic system |

Undercarriage Wear | Tracks wear out fast and hurt movement |

Engine Problems | Overheating and other engine problems |

Electrical Malfunctions | Electrical issues that show up |

Overheating | Engine overheating that hurts how it works |

Won’t Start

You try to start your excavator, but it does not start. This is one of the most annoying problems. Don’t worry—most times, you can fix it yourself.

Here are the most common reasons it won’t start:

Dead battery or loose wires. Check the battery and make sure the cables are tight.

Safety switch trouble. If a safety switch breaks, the mini won’t start.

Fuel system blockage. Dirt can block the fuel line.

Bad starter motor or loose wires. Wires can come loose after a while.

Note: Many people forget to check the battery or safety switches. Always start with these easy steps.

If your excavator won’t start, ask yourself:

Did you leave the lights on and drain the battery?

Are all safety switches set right?

Is there enough fuel in the tank?

Do you hear a click when you turn the key?

You can fix many starting problems by checking these things. If your mini still won’t start, read the operator’s manual or call DeepKron support.

Slow or Jerky Movements

You want your mini excavator to move smoothly. If it moves slow or jerky, something is wrong.

Common causes are:

Low hydraulic fluid. The system needs enough fluid to work.

Air in the hydraulic lines. Air bubbles can make the mini jump.

Dirty or blocked filters. Filters keep things clean. If they clog, the mini slows down.

Worn tracks. Tracks that wear out fast make the excavator move unevenly.

Tip: Always check the tracks and hydraulic fluid before you work. This easy step can stop many problems.

The ground and weather matter too. If you work on rough ground or in bad weather, your mini may have more trouble. Pick the right machine for your job and watch the ground.

Overheating

Engine overheating is a big worry for many people. If your mini gets too hot, it can stop or get damaged.

The most common reasons for overheating are:

Leaks inside the hydraulic system. This makes the engine work harder and get hotter.

Blocked coolers. Dirt blocks the cooling system, especially in hot weather or heavy work.

Low oil levels. Not enough oil means heat builds up in some parts.

Warning: Never ignore the temperature gauge. If you see the needle go up, stop and let your mini cool down.

To stop overheating, check the cooling system and oil before each job. Clean the coolers and make sure nothing blocks the air. If your mini runs hot, take a break and check the machine.

Many people make mistakes when fixing problems. They forget to read the manual, skip daily checks, or load the machine wrong. Don’t make these mistakes to keep your mini working well.

Mini Excavator Maintenance Issues

You need to keep your mini excavator in good shape. Watch for problems that happen a lot. Doing regular maintenance helps you stop most issues. There are three main things you should check often.

Greasing Problems

Grease your mini excavator every day. If you forget, parts can wear out fast. Dry pins and bushings make the machine work harder. This can cause engine trouble later. Your manual shows all the places to grease. Greasing helps your mini run smooth and saves money on repairs.

Tip: Grease your mini every day. It only takes a few minutes. This step helps you avoid many problems.

Track Tension

Track tension is very important. If tracks are too loose, they can fall off. This stops your work. If tracks are too tight, they hurt the undercarriage. Tight tracks also use more fuel. Both problems wear out your mini faster. Check track tension often as part of maintenance.

Loose tracks can fall off and waste time.

Tight tracks damage the undercarriage and use more fuel.

The right tension keeps your mini working well.

Undercarriage Damage

The undercarriage gets worn out every day. You may see track wear or roller damage. Sprockets can get damaged too. These problems happen to all minis. If you ignore them, your mini loses traction and uses more fuel. Misalignment causes uneven wear and costs more to fix. Regular maintenance helps you find these problems early.

Regular maintenance keeps your mini safe. It lowers repair costs and helps your machine last longer.

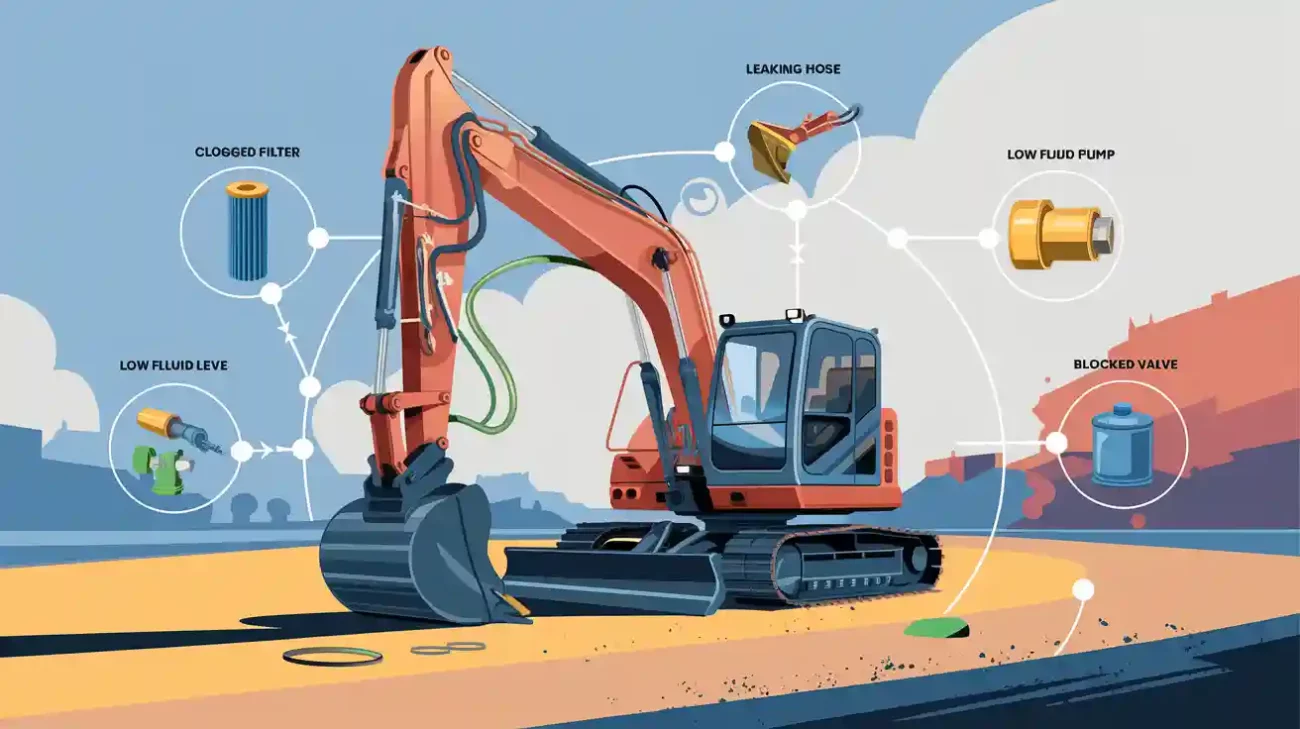

Hydraulic and Electrical Issues

Mini excavators work hard every day. You might see hydraulic system issues or electrical problems pop up. These are some of the most common excavator problems. Let’s break down what you should look for and how you can fix them.

Hydraulic Leaks

Hydraulic fluid leaks can slow down your mini and make a mess. You need to check for leaks often. The hydraulic system is complex, but you can spot trouble early if you know where to look. Here are the main causes of leaks:

Worn hoses or connectors

Loose clamps

Damaged cylinders

Bad seals

If you see fluid under your excavator, stop and inspect the hoses and connectors. Regular maintenance helps you catch leaks before they get worse. Always check the hydraulic system before you start your mini.

Tip: Clean up any fluid spills right away. This keeps your work area safe and helps you spot new leaks.

Pump Wear

The hydraulic pump keeps your mini moving. If the pump wears out, you might notice slow or weak movements. You could hear strange noises from the engine or see the mini struggle to lift loads. Pump wear happens over time, especially if you skip maintenance or use the wrong fuel. Always use the right oil and follow the schedule in your manual. If you notice changes in how your mini works, check the pump first.

Electrical System Troubles

Electrical issues can stop your mini excavator fast. You might see warning lights or have trouble starting the engine. Here’s a table showing the most frequent electrical problems in mini excavators:

Electrical Issue | Description |

|---|---|

Control Panels | Vibration and humidity can loosen parts and cause failures. |

Relays | Malfunctions may lead to alarms or instrument problems. |

Cables | Damage from weather can hurt performance. |

Battery Problems | Often cause starting failures. |

You should also watch for wiring problems and sensor malfunctions. If you notice flickering lights or alarms, check the battery and cables first. Regular checks help you avoid common issues and keep your mini running strong.

Final Drive Motor and Other Common Issues

Final Drive Motor Problems

The final drive motor helps your mini move and turn. If you notice your excavator losing power or making strange noises, the final drive motor might have a problem. Sometimes, you might see oil leaking near the drive area. If your mini struggles to climb or turn, stop and check the motor. Dirt and debris can get inside and cause damage. Always keep the area clean and check for leaks during your daily maintenance. If you hear grinding or feel shaking, it’s time to look closer at the final drive motor.

Tip: Listen for new sounds when you operate your mini. New noises often mean something needs attention.

Loose or Worn Parts

Loose or worn parts can cause many common issues in mini excavators. You might see tracks slipping off or not lining up right. This often means the idler is worn. Look for these signs:

Tracks slipping off or misaligned, which shows a worn idler.

Uneven patterns or cracks on the idler surface.

Irregular track tension that affects how your mini works.

Rust or corrosion that weakens the idler.

If you spot any of these, fix them right away. Ignoring loose or worn parts can lead to bigger problems and more downtime for your mini.

Bad Zerks and Dry Pins

Greasing is a key part of mini excavator maintenance. Bad zerks and dry pins can cause trouble fast. When zerks don’t work, your mini doesn’t get enough grease. This leads to more friction and faster wear on moving parts. Here’s what can happen:

More friction means your mini won’t last as long or work as well.

You need to grease your mini the right way. Under-greasing increases friction and can cause breakdowns. Over-greasing can damage seals and attract dirt, which leads to more wear. Always check your zerks and pins during your daily maintenance. If you see dry spots, add grease right away.

Note: Keeping your mini well-greased helps prevent many common issues and keeps your excavator running strong.

DeepKron Solutions for Common Issues

When to Call a Technician

You can fix some mini problems by yourself. But sometimes, you need a trained technician. DeepKron wants you to be safe and keep your mini working well. Here are signs you should call for help:

You see hydraulic system problems, like leaks or less power.

The undercarriage is damaged or has too much dirt you can’t clean.

Parts look too greasy or too dry, and you can’t fix it.

Track tension is not right, and you can’t adjust it.

The final drive motor makes odd noises or leaks oil.

If you see these problems, stop using your mini. Call DeepKron service for quick and trusted help. DeepKron technicians know how to fix mini excavators. They use the best tools and parts for repairs.

Tip: If you are not sure about a repair, ask DeepKron’s experts. They can help you avoid bigger problems.

Using DeepKron Support

DeepKron gives many ways to help mini owners. You get support, manuals, and approved parts. The DeepKron website has guides and videos for common problems. You can find answers to most questions there.

Here’s how DeepKron support helps you:

Solution Type | What You Get |

|---|---|

Manuals | Simple steps for mini maintenance |

Service Hotline | Quick answers from experts |

Approved Parts | Good parts for your excavator |

Online Resources | Videos and guides for help |

Doing regular maintenance with DeepKron-approved parts helps your mini last longer. Always use your operator’s manual and DeepKron resources for the best results.

Note: DeepKron works hard to give you the best support and new ideas for your mini.

Stay calm when your mini has issues. Use this checklist to keep your mini excavator running strong. Trust DeepKron’s support and maintenance tips for fewer problems. Remember, daily checks on your mini save money and time.

“Properly maintaining your mini excavator is the key to years of care-free work.”

FAQ

What should I do if my mini excavator won’t start?

First, check the battery and safety switches. Make sure you have fuel. If it still won’t start, look at your manual or call DeepKron support.

How often should I grease my mini excavator?

You should grease your mini every day. This keeps parts moving smoothly and helps prevent breakdowns. Always follow the guide in your operator’s manual.

Where can I find DeepKron-approved parts and support?

Resource | How to Access |

|---|---|

DeepKron Website | |

Service Hotline | Check your manual for number |

Manuals | Included with your machine |