When your mini excavator won’t start, it can be frustrating. Many people encounter this issue due to a few common reasons. These often include:

Problems with the starter motor

Weak battery or loose wires

Blocked fuel lines

Mechanical issues in the engine

Faulty electrical wiring

You can inspect most of these problems using simple tools and some time. Always prioritize safety—turn off the engine, secure the area, and wear appropriate safety gear before beginning any checks.

Key Takeaways

Always look at the battery first. Test its voltage. Check the cables for rust or if they are loose.

Look at safety switches and controls. Make sure the emergency stop and seat switches are set right.

Keep fuel and air systems clean. Use fresh fuel. Change filters often. Check for things blocking the system.

Check wires and mechanical parts for damage. Look for loose connections or old fluids. This helps stop starting problems.

Do regular maintenance. Call DeepKron support if problems do not go away after these checks.

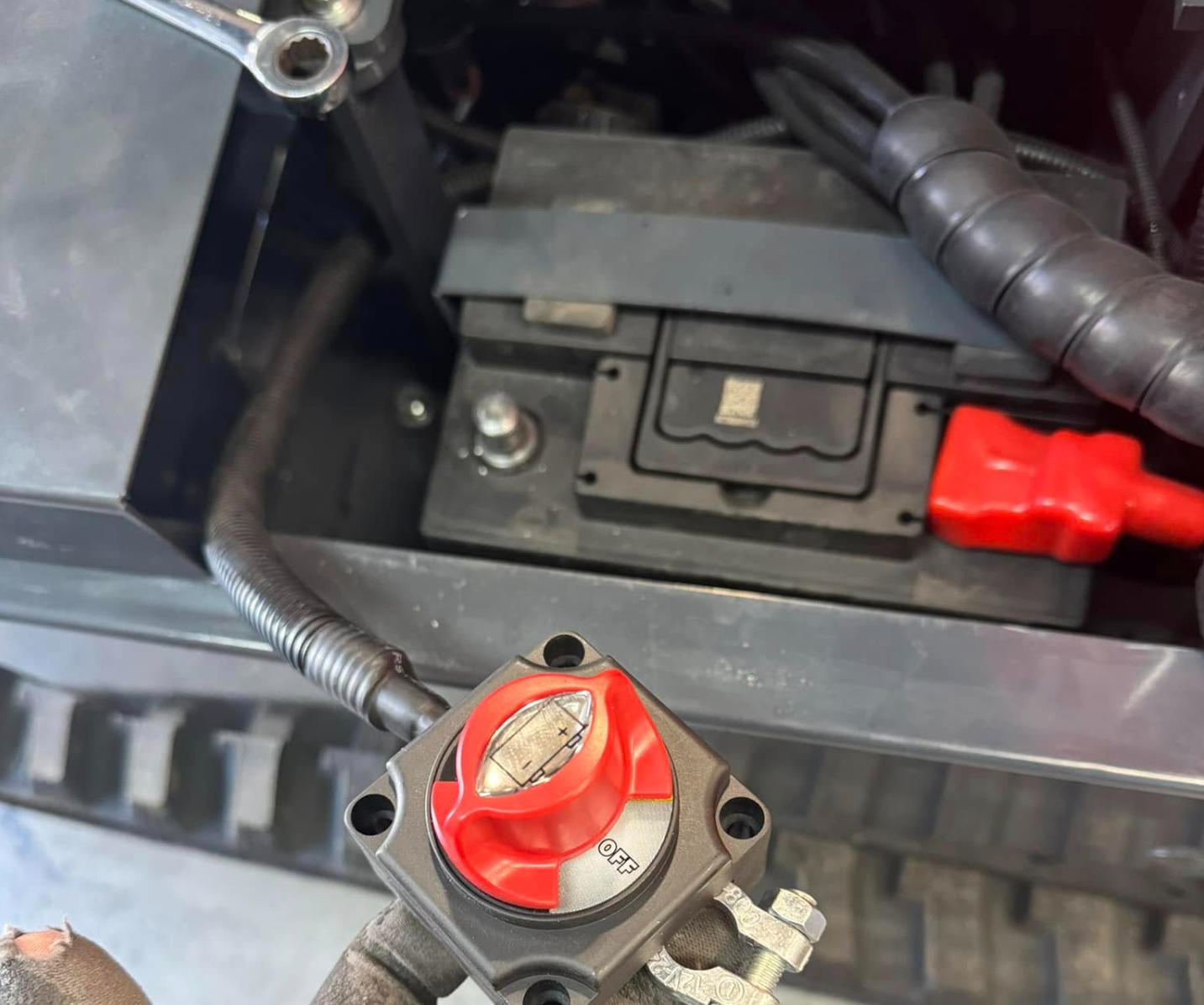

Mini Excavator Won’t Start: Battery and Electrical

DeepKron Battery Check

If your mini excavator won’t start, check the battery first. DeepKron uses strong batteries, but they still need checking often. Use a multimeter or the machine’s gauge to see the battery voltage. A good battery should show about 12.6 volts when charged. If the number is lower, the battery might be weak or dead. Make sure the battery isolator switch is set right. Leaving lights on or cold weather can drain the battery. DeepKron says to check the battery before every use to stop problems.

Tip: Always turn off the engine and wear gloves before you touch the battery.

Cables and Connections

Loose or dirty cables can keep your mini excavator from starting. Look for white powder on the battery terminals. This means there is corrosion. Gently move the battery cables. If they wiggle, tighten them. Check for wires that are cut or damaged. These can cause shorts or make the electrical system fail. Look at the ignition switch and connectors for damage. Clean all the connections and make sure the wiring is tight. Test fuses and relays if you think there is a problem. Use a multimeter to check for voltage drops. DeepKron machines have strong wiring, but checking often helps stop trouble.

Common signs of faulty cables or connections:

Loose battery connections

Damaged wiring harness

Faulty ignition switches

Electrical system failures

Starter Motor

If the battery and cables are okay, look at the starter motor. First, check if the starter is getting enough power. Make sure the battery sends the right voltage to the starter. Look at wires and connectors for damage or rust. Clean the outside of the starter motor to keep dust away. Lubricate moving parts as DeepKron suggests. For hydraulic starter motors, check oil levels and look at pumps and valves. Test sensors and switches to make sure they work right. Do regular maintenance like changing filters and checking sensors. If your mini excavator still won’t start, call DeepKron support for help.

Safety Switches and Controls

DeepKron Safety Switches

DeepKron mini excavators have many safety switches. These switches help keep you and your machine safe. They stop the machine from starting if something is not right. Service data shows safety switch problems are a top reason a mini excavator won’t start. Some common problems are seatbelt switches not fastened, control levers not set right, or hydraulic lockout switches not turned on. If any switch is broken or not in the right spot, your machine will not start. This happens even if the battery and starter work fine.

Tip: Always make sure all safety switches are in the right place before you try to start your mini excavator.

Emergency Stop and Operator Presence

You should check the emergency stop button before starting. If this button is pushed in or stuck, the engine will not get power. The machine will not start. Operator presence switches, like the seat switch, are also important. If you are not sitting right or the seat switch is broken, the engine will not start. These switches work together to keep you safe. They make sure the machine only runs when you are ready and in control.

Common issues to look for:

Emergency stop button pushed in

Operator not sitting right

Broken seat or armrest switches

Control levers not lined up

Key Switch and Security Codes

The key switch lets power go to the starting system. If the key switch is broken, it stops the starter from working. Some mini excavators use security codes or start disable relays. If you type the wrong code or the relay does not close, the engine will not turn on. You can check the key switch by turning it on and testing for power at the starter relay. If there is no power, the key switch or relay may be the problem. Always use the right security code and check all switches before you try to start the machine.

If your mini excavator won’t start after checking these controls, check each safety switch and control again. Small things like a lever not lined up or a kill switch turned on can stop the machine from starting.

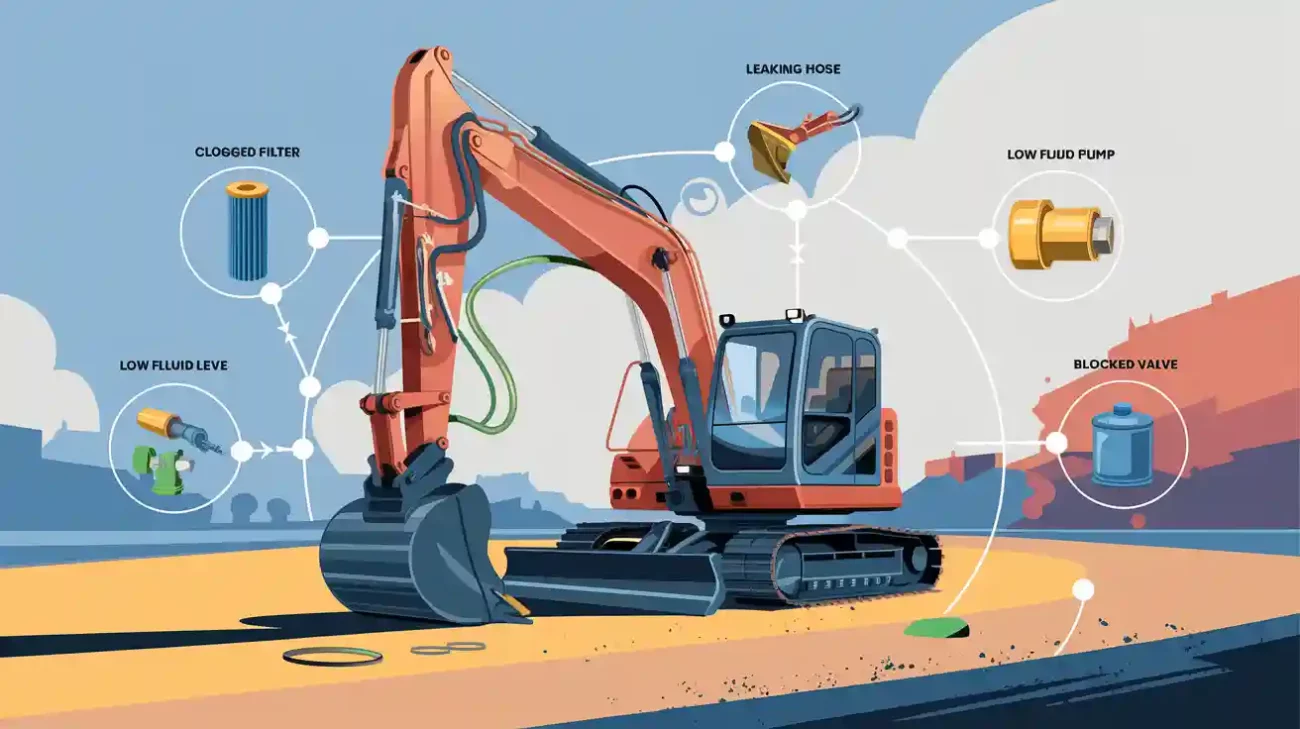

Fuel and Air System

Fuel Level and Quality

Check the fuel level first if your mini excavator won’t start. Low fuel or bad diesel can stop the engine from running. Old fuel might have water or dirt in it. This can block the system. Always use clean, fresh fuel and fill the tank before work. If the fuel looks cloudy or dark, drain it and put in new fuel. Very hot or cold weather can change fuel quality. Humidity can also hurt fuel. Keep fuel in a cool, dry place to stop it from getting dirty.

Tip: Look at the fuel tank for leaks or rust before you add fuel. Clean the cap and area around it to keep dirt out.

Fuel Lines and Filters

Blocked fuel lines or dirty filters can make starting hard. Watch for these signs:

The engine sputters or hesitates when you start it.

Power drops when you speed up.

The engine stalls or misfires.

You hear hissing or whining from the fuel pump.

Black smoke comes out during heavy work.

The engine cranks longer in cold weather.

Symptom | Explanation |

|---|---|

Not enough fuel gets to the engine. | |

Difficulty Starting the Engine | A blocked filter stops fuel pressure from building up. |

Rough or Unstable Idle | Uneven idle happens from poor fuel flow. |

Engine Stalling | Clogged filter lets only a little fuel through, so it stalls. |

Sputtering or Hesitation | The filter cannot give enough fuel fast. |

Noisy or Failing Fuel Pump | The pump works harder and may break. |

Visible Contaminants in Filter | Water, sludge, or rust show the filter is clogged. |

Change fuel filters often and check lines for cracks or leaks. Clean or replace filters if you see any of these problems.

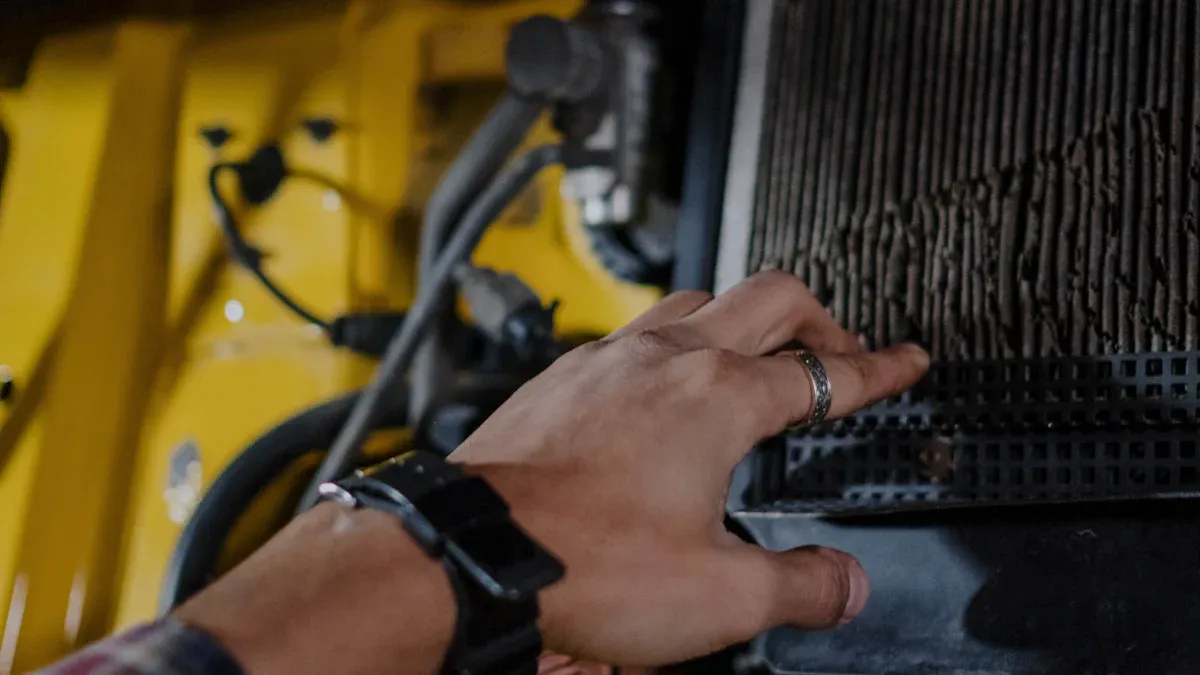

Air Filter and Intake

A dirty air filter makes it hard for the engine to get air. This can stop the engine from starting. Check the air filter every day. Take off dust and dirt from the filter and intake. If the filter looks dark or full, put in a new one. Clean air helps the engine burn fuel well and start easy. If the air filter blocks air, the engine works harder and may stall or run rough. Dirt can also hurt engine parts if it gets through a bad filter.

Note: In dusty or wet places, check and clean the air filter more often. Good care keeps your mini excavator working well.

Wiring and Other Mechanical Checks

Wiring and Connections

Wiring problems often cause starting issues in mini excavators. You should check all wiring and connectors for signs of damage or wear. Start by disconnecting the battery to stay safe. Look for loose or corroded battery terminals. Clean them if you see any dirt or white powder. Use a wrench to tighten any loose bolts. Check for frayed wires, pinched cables, or spots where rodents may have chewed the insulation.

Use a digital multimeter to test for voltage and continuity. Make sure fuses and relays are not burnt or loose. If you find a blown fuse, replace it with one that matches the original rating. Inspect all sensor wires for breaks or shorts. If you see any damaged wiring, replace it with parts that match DeepKron’s standards. When reconnecting electrical contacts, use a contact lubricant to help prevent corrosion and ensure a good connection.

Tip: Wear anti-static gloves and work in a static-free area to protect sensitive electronics.

Common wiring faults include:

Poor contact at power supply lines

Burnt or loose fuses and relays

Broken or shorted sensor wires

Damaged cables from rodents

Engine Oil and Fluids

Proper fluid levels help your mini excavator start and run well. Check engine oil, coolant, and hydraulic fluid every day. Look at the oil dipstick and make sure the oil sits between the MIN and MAX marks. Use the oil type recommended by DeepKron, such as 15W-40. For coolant, check the reservoir and keep the level between the marks. Use only the coolant type listed in your manual. Check hydraulic fluid with the dipstick or sight glass and top up if needed.

Low oil or coolant can cause engine damage or overheating. This may make it hard for the engine to start or keep running. Always use clean, fresh fluids and look for leaks under the machine.

Hydraulic fluid: Top up as needed

Diesel fuel: Use ultra-low sulfur diesel

When to Call DeepKron Support

If you have checked all wiring, fluids, and controls but your mini excavator won’t start, it is time to call DeepKron support. Some problems need expert tools or knowledge. DeepKron’s support team can guide you through advanced troubleshooting or arrange for a technician to visit. Always have your machine’s model and serial number ready when you call. This helps the support team give you the best advice quickly.

Note: Regular checks and maintenance help prevent most starting problems. If you face a complex issue, DeepKron is ready to help you get back to work.

If your mini excavator will not start, check things one by one. This helps you find the problem fast and stay safe. You can get help from:

Checking your machine often so it works better

Wear the right gear and follow safety rules every time. Check fluids and clean filters to keep your machine working well. If you still cannot fix it, ask a trained technician or DeepKron support for help.

FAQ

What should you check first if your mini excavator will not start?

Start with the battery. Use a multimeter to check voltage. Look for loose or corroded cables. Make sure the battery isolator switch is on. These steps help you find the most common problems quickly.

How often should you change the fuel and air filters?

You should check filters every day before use. Change fuel and air filters as DeepKron recommends in your manual. Dirty filters can block fuel or air and stop your engine from starting.

Can cold weather stop your mini excavator from starting?

Yes, cold weather can thicken oil and drain the battery. Use the right oil for the season. Keep your battery charged. Warm up the engine if possible before starting.

What does it mean if you hear a clicking sound but the engine does not start?

A clicking sound usually means the battery is weak or the starter motor has a problem. Check the battery voltage. Tighten all cables. If the problem continues, contact DeepKron support.

Where can you get help if you cannot fix the problem?

You can contact DeepKron support for expert help. Have your machine’s model and serial number ready. The support team can guide you or send a technician if needed.