You can keep your mini excavator safe by doing regular idle maintenance when you are not using it. Easy things like checking fluids, cleaning often, and storing your 2 tonne excavator the right way help stop expensive repairs. These steps also make your machine worth more if you sell it. Equipment that is cared for works safer and lasts longer. DeepKron makes each machine with good quality and new ideas. This helps you keep your compact equipment ready for any job.

Key Takeaways

Check fuel, oil, and coolant often. This helps your mini excavator stay ready. It also stops engine problems.

Clean your machine every day. Change filters to keep dirt out. This helps parts work well.

Look at moving parts a lot. Grease them to stop wear. This makes your excavator last longer.

Keep your mini excavator on flat, dry ground. Use covers to protect it from weather. This stops rust.

Take care of the battery. Charge it before you store it. Stop corrosion so it starts well.

Fuel & Fluids

Diesel and Gasoline Care

Both the DeepKron DK16P and DK12P mini excavators use reliable Briggs & Stratton gasoline engines. You need to take special care of the fuel system when your machine sits idle. Gasoline can break down over time, which may cause engine problems later. To keep your excavator ready, follow these steps:

Add a fuel stabilizer to the tank before storage. This keeps the gasoline fresh and prevents it from degrading.

Fill the tank to reduce air space and stop moisture from building up inside.

Store your mini excavator indoors if possible. If not, cover it with a tarp to protect it from rain and sun.

Drain water from the hydraulic system to avoid damage.

These preventive measures help you avoid costly repairs and keep your machine in top shape.

Engine Oil and Coolant Checks

You should check engine oil and coolant levels every day, even when the excavator is not in use. This simple habit protects your engine from damage. Here is what you need to do:

Use the dipstick to check the oil before starting the engine. Make sure the oil level is between the marks and looks clear.

Check the coolant in the expansion tank when the engine is cold. The coolant should be above the minimum line and free from rust or debris.

Perform these checks daily to keep the engine lubricated and cool.

Regular checks help you spot problems early and keep your excavator running smoothly.

Fuel/Water Separator Maintenance

Water in the fuel can harm your engine. The DK16P and DK12P have a clear fuel/water separator bowl with a red ring. You should inspect this part during downtime:

Look at the separator bowl. If the red ring floats, water is present in the fuel.

If you see water, fix any leaks in the fuel filter right away.

If the ring does not float, your fuel is clean.

For deeper maintenance, close the fuel valve, remove the old filter, and install a new one with a bit of engine oil on the seal.

Open the drain valve at the bottom of the tank to remove water and impurities.

Tip: Always check the clarity of your fuel. If it looks cloudy or has too much water, inspect the tank cap seal for damage.

Daily Maintenance

Keeping your 2 tonne excavator in top condition during downtime starts with a solid daily maintenance routine. DeepKron mini excavators make this process easier with smart features like AI sensors, real-time alerts, and quick couplers for fast attachment changes. These innovations help you spot problems early and reduce the time you spend on upkeep.

Cleaning and Filter Replacement

Dirt and debris can cause big problems for your mini excavator if left unchecked. You should clean your machine every day, even when it is not in use. Pay special attention to the undercarriage, engine compartment, and radiator. Use a brush or low-pressure water to remove mud and dust. This simple step helps prevent rust and keeps moving parts working smoothly.

Tip: Always check and clean the air filters. Replace them if they look dirty or clogged. Clean filters keep your engine running strong and protect it from damage.

You should also inspect the fuel and hydraulic filters. Replace them as needed to avoid blockages that can harm your 2 tonne excavator. Keeping filters clean is one of the best ways to maintain idle mini excavator and avoid costly repairs.

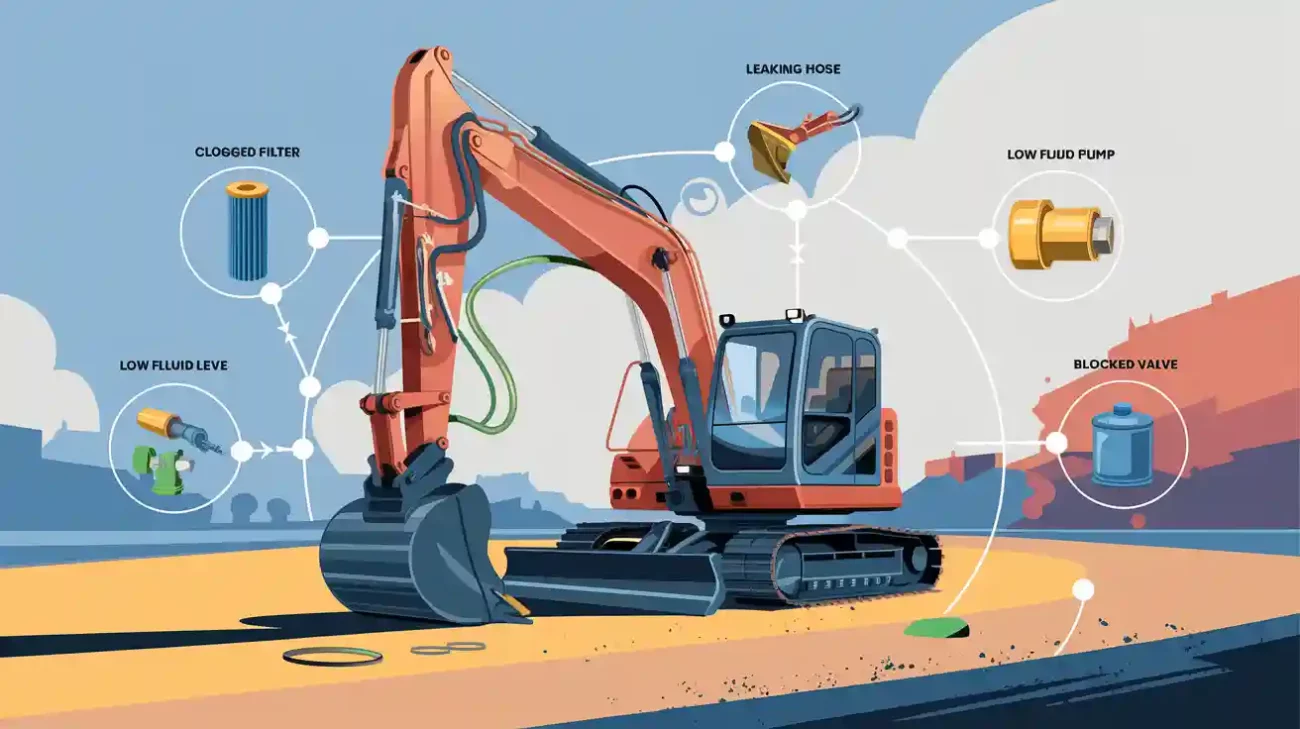

Hydraulic System Inspection

The hydraulic system is the heart of your mini excavator. You need to check it often, even during downtime. Start with a daily walk-around. Look for leaks, worn hoses, or loose fittings. Make sure the hydraulic oil level stays within the recommended range. If you see any oil on the ground or around the hoses, fix the problem right away.

Inspect hoses and fittings for cracks or wear.

Check the oil level and top up if needed.

Clean the hydraulic parts to remove dust and grime.

For machines not in regular use, plan a deeper inspection before and after long storage. Drain and replace the hydraulic fluid if the machine will sit for a season. This keeps your 2 tonne excavator ready to work when you need it.

Greasing Moving Parts

Lubrication is key to preventing wear and tear on your mini excavator. You should grease all pivot points, pins, and bushings every day. Use the grease recommended in your DeepKron manual. Too little grease causes parts to wear out fast. Too much grease can trap dirt and cause other problems.

Wipe away old grease and dirt before adding new grease.

Give each fitting one to three shots of grease.

Pay extra attention to the bucket, boom, and arm joints.

Note: Grease the slew bearing every 50 hours or as your manual suggests. Track rollers and idlers may need weekly greasing.

Regular maintenance like this helps your mini excavator last longer and perform better. Keep a log of your daily checks and greasing. This record supports warranty claims and helps you track the health of your machine.

Battery Care

Taking care of your mini excavator’s battery during downtime helps your machine stay ready. The DeepKron DK16P and DK12P models use strong batteries. You need to do a few things to keep them working well, especially in winter.

Removal and Storage

If you will store your mini excavator for a long time, take out the battery. This stops power loss and keeps cold weather from hurting it. Here is what you should do:

Unplug the battery from your mini excavator so it does not lose power.

Put the battery in a cool, dry spot. Make sure it stays warmer than 32°F (0°C).

Charge the battery all the way before you store it. A full battery lasts longer and works better when you use it again.

If your battery lets you, check the electrolyte level.

Use a battery box or battery management system to keep the battery safe from bumps and water.

Charge the battery every few weeks while it is stored. This keeps it healthy.

Tip: If you cannot take out the battery, turn off the battery switch or unplug the cables. Start the engine and run your mini excavator for a few minutes every two weeks. This keeps the parts oiled.

Preventing Corrosion

Corrosion can make your battery die sooner. You can stop this by doing a few easy things:

Look at the battery ends for white or green stuff. If you see it, clean the ends with hot water.

After cleaning, put a thin layer of vaseline on the ends. This keeps water away and stops corrosion.

Make sure the battery cables are tight. Use a wrench to tighten them to 8-10 N·m.

Store the battery in a place with good air flow, steady temperature, and low moisture. Use a dehumidifier if you need one.

Do not put the battery in direct sunlight or wet places.

If you follow these steps, you protect your DeepKron mini excavator’s battery. Your machine will start up strong after downtime.

Storage Tips

Positioning and Covering

Always park your mini excavator on flat, dry ground. This stops water from building up under the tracks. It also helps stop rust from forming. If you cannot store your 2 tonne excavator inside, use a tarp or cover that lets air through. This keeps rain, snow, and dust off your machine. Make sure the cover fits well and does not hold in water. Clean your excavator well before you store it. This helps you find any damage and keeps your equipment in good shape.

Tip: Check your machine once a month while it is stored. Look for leaks, worn hoses, or loose parts early.

Cabin and Sun Protection

It is important to protect the cabin. This keeps the controls and electronics safe. Close all windows and doors to keep out bugs and water. Use a sunshade or UV cover if your mini excavator stays outside. Sunlight can make paint fade and hurt rubber seals. The best place to store your machine is inside or in a climate-controlled spot. This keeps the cabin safe from big changes in temperature and makes it comfortable to use later.

Storage Location | Protection Needed |

|---|---|

Indoors | Basic dust cover |

Outdoors (mild) | Breathable tarp, sunshade |

Outdoors (harsh) | Fitted cover, UV shield |

Periodic Engine Runs

Start the engine every few weeks when you are not using it. This is called idle running. It keeps fluids moving and stops seals from drying out. Let the engine run for a few minutes to move oil and coolant. Check fluid levels before and after you run the engine. If you see leaks or hear strange sounds, fix them right away. Idle running helps your 2 tonne excavator stay ready for work.

Note: Pull in hydraulic cylinders or put oil on the rods before storage. This keeps the hydraulic system safe from rust and wear.

Winter Maintenance

Winter can be tough for your mini excavator. Cold weather may hurt important parts if you skip maintenance. You should focus on coolant, hydraulic hoses, and warming up the engine to keep your DeepKron machine ready.

Coolant and Antifreeze

Coolant keeps your engine from freezing or rusting. Use a coolant that meets ASTM D-621 standards. Mix it with water, half and half, to protect down to -34°F. This mix stops rust and helps the engine run well. If you live where it is very cold, use a 40/60 mix with demineralized water. This helps stop minerals from building up and protects aluminum parts. Always look at the coolant for cloudiness or bits floating in it. Change it if you see any problems. Check hoses and clamps every two years to stop leaks. Block heaters keep fluids warm and help you start your mini excavator in the cold.

Tip: Drain all the coolant if you will store your machine for a long winter.

Hydraulic Hose Protection

Hydraulic hoses can crack or leak when it is freezing. Use hydraulic fluid made for cold weather so it flows well. Before storage, let the engine idle and move all controls to let out pressure. Pull the hydraulic cylinders all the way in to keep the rods safe from rust. If you cannot pull them in, put clean hydraulic oil on the rods. Look at all seals and hoses for damage. Change any worn parts to keep water out.

Step | Action |

|---|---|

Fluid Selection | Use cold-weather hydraulic oil |

Depressurize System | Idle engine, cycle controls |

Cylinder Care | Retract rods, oil if needed |

Inspection | Check seals, replace if worn |

Engine Warm-Up

Starting your mini excavator in the cold needs extra care. After you start the engine, let it idle slowly. Watch the temperature gauges in the cab. Move the boom, bucket, and blade slowly to warm up the hydraulic fluid. This takes a few minutes but helps everything work better. Clear snow and ice off your machine before you start. At the end of the day, let the engine idle for two minutes before turning it off. Block heaters and coolant heaters help you start the engine and protect your battery.

Note: Always check hoses and rods before and after warm-up to find any cold damage early.

You keep your mini excavator safe when you look after it during downtime. Easy things like checking fluids, cleaning, and greasing parts help you save money. Many companies have fewer breakdowns and spend less when they do these things. Machines that get good care last longer and work better, even when the job is hard. DeepKron gives you strong and smart solutions so your equipment is always ready to use.

FAQ

How often should you check fluids during downtime?

Check fluids once a week. This means engine oil, coolant, and hydraulic fluid. Checking often helps you find leaks or low fluid early. Your DeepKron manual tells you the best schedule for your machine.

What is the best way to store your mini excavator battery?

Take out the battery and put it in a cool, dry spot. Charge it all the way before you store it. Check the battery charge every few weeks. Use a battery box to keep it safe.

Tip: Clean battery ends to stop corrosion.

Can you leave attachments on your mini excavator during storage?

You can keep attachments on, but clean them first. Grease all moving parts well. Cover sharp edges so they do not rust. Store extra attachments inside if you can.

Attachment Type | Storage Advice |

|---|---|

Bucket | Grease and cover |

Hydraulic Thumb | Retract and oil |

How do you prevent rust on your mini excavator?

Wash your machine before you store it. Dry every part well. Use a cover that lets air through. Grease metal parts that show. Look for rust every month and fix it fast.

What should you do if your mini excavator will not start after downtime?

Check if the battery has power first. Look at fuel and fluid levels. See if wires are loose or rusty. If it still will not start, ask DeepKron support for help.