Looking for ways to get more done with a DK16P Mini Excavator? Contractors know this small excavator helps finish jobs faster and more accurately. Operators who plan well and use easy controls work better. Regular maintenance keeps the machine working well. Ergonomic features help workers feel less tired. The DK16P Mini Excavator is flexible. It lets users change attachments and do many jobs. A compact excavator saves both time and money. This makes it great for busy teams. Check out More Mini Excavators for Sale if you want to work better with the right tools.

Key Takeaways

Doing daily maintenance and checking tracks helps the DK16P Mini Excavator work well. It also stops expensive problems from happening. Using the correct attachments and switching them quickly lets you do more jobs faster. It also makes work easier. Changing the seat and using ergonomic features helps operators feel good. They can work longer without getting tired. Planning the jobsite with clear work areas and smart material placement saves time. It also saves fuel and keeps work going. Smart technology and work modes make the machine work better. They save fuel and help finish projects faster and safer.

Maintenance

Taking care of the DK16P Mini Excavator starts with easy daily steps. Doing regular maintenance helps the machine work well and last longer. Operators who check their compact excavator every day have fewer problems and get more work done.

Daily Checks

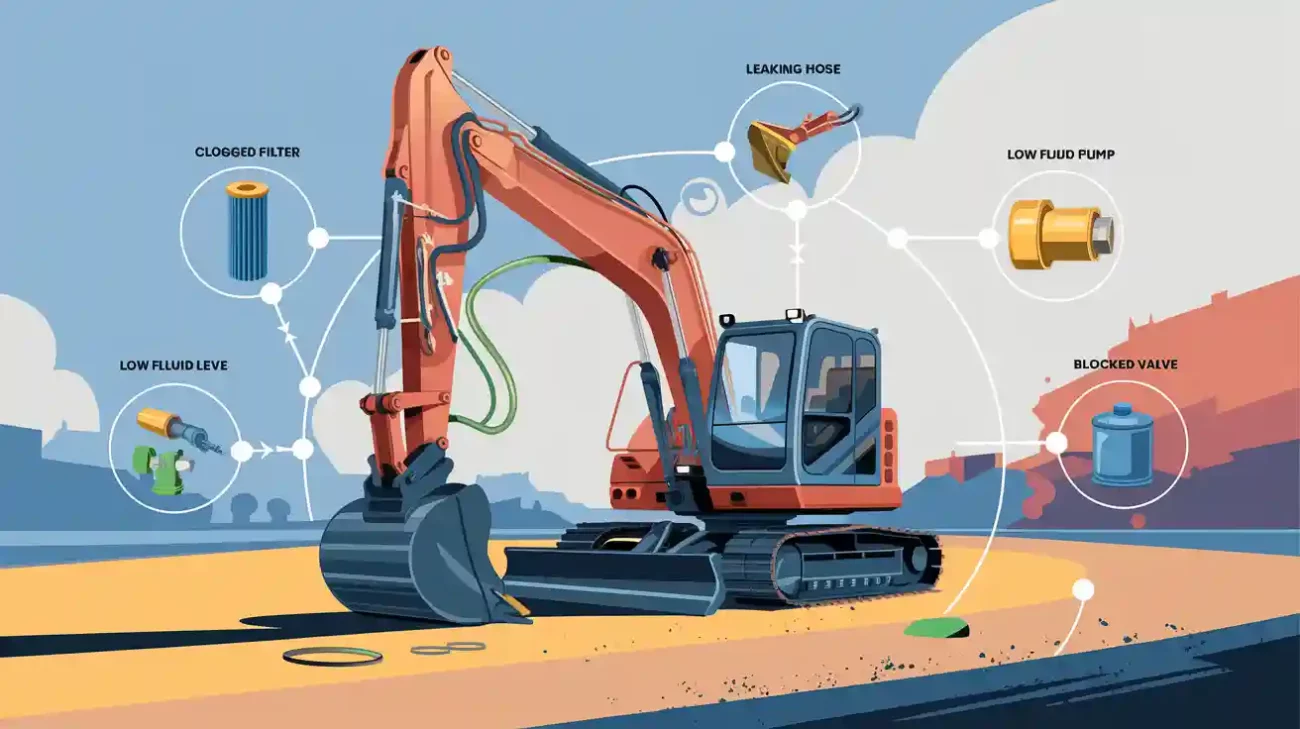

Daily checks help find small issues before they get worse. Operators should look at fluid levels, filters, and the undercarriage before starting. The DK16P Mini Excavator has a smart design and panels that are easy to open. Checking for leaks, loose parts, or dirty filters keeps the mini excavator working well. If operators see problems early, they can fix them quickly and avoid losing time.

Tip: Use a simple log to write down what you check and fix. This helps with warranty claims and keeps the compact excavator ready to use.

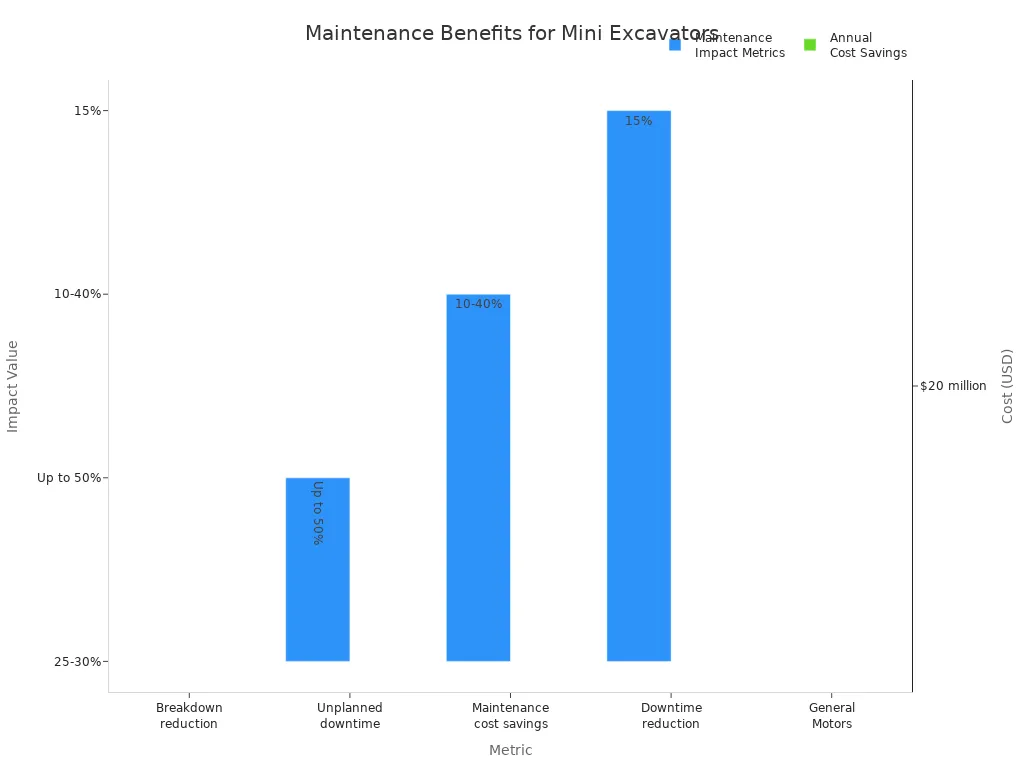

Here’s how regular maintenance helps performance and costs:

Metric / Example | Result / Impact | Context / Source |

|---|---|---|

Reduction in equipment breakdowns | Predictive maintenance studies | |

Unplanned downtime reduction | Up to 50% reduction | Industry-wide data |

Maintenance cost savings | 10-40% savings | General construction operations |

Equipment lifespan extension | Achieved through proactive scheduling | Supported by case studies |

Downtime reduction | 15% reduction | General Motors case example |

Annual cost savings | $20 million | General Motors |

Real-time monitoring benefits | Early detection of faults, reduced downtime | IoT sensor data and AI systems |

Fuel efficiency improvement | Improved by regular servicing | Fuel consumption studies |

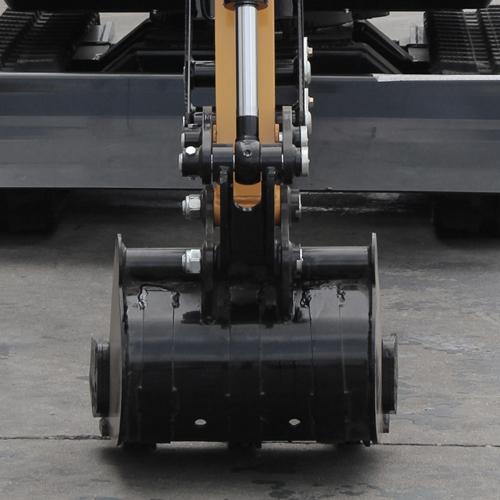

Track Inspection

Track inspection is important for every compact excavator. Operators should look for dirt, cuts, or missing pieces in the tracks. Cleaning and adding oil to the tracks every day helps stop rust and wear. Keeping the track tight makes the mini excavator strong and stops breakdowns. Looking at the tracks often helps find damage early, keeps the job site safe, and lets you work more.

Checking the tracks every day can stop about 70% of common problems. This means more time working, better results, and higher efficiency for each project. Operators who use a checklist and keep notes help the DK16P Mini Excavator last longer.

Doing regular maintenance is the best way to keep the compact excavator working hard every day.

Attachments

Attachments help the DK16P Mini Excavator do many jobs. Operators can change tools fast. This saves time and lets them do more work. Picking the right attachment makes the compact excavator more useful.

Quick Swaps

The DK16P Mini Excavator can use many attachments. Breaker hammers break concrete. Scarifiers loosen hard ground. Rotary drilling rigs dig deep holes. Mud buckets are good for wet dirt. Hydraulic thumbs and dozer blades help with lifting and grading. Quick hitches let you switch tools fast. The mini can go from digging to demolition in just minutes.

Tip: Keep attachments clean and in order. This helps you swap them faster and keeps the compact excavator ready for work.

Here are some popular attachments and what they do:

Attachment | Common Applications |

|---|---|

Breaker Hammer | Demolition, concrete work |

Scarifier | Site prep, road building |

Rotary Drilling Rig | Well drilling, foundations |

Mud Bucket | Wet digging, cleanup |

Hydraulic Thumb | Lifting, debris removal |

Dozer Blade | Grading, leveling |

Quick Hitch | Fast tool changes |

Operators use these tools for landscaping, farming, and building. The mini’s quick-attach system makes swaps easy. This helps the compact excavator do many different jobs.

Hydraulic Setup

A good hydraulic setup helps the mini work well. Put the oil pump radiator where air can flow. This stops it from getting too hot. Make sure brackets and bolts are tight. This keeps the machine from shaking too much. Place hoses carefully to stop leaks. Get rid of air in the system after you install parts.

Note: Check hoses, clamps, and seals often. Change any worn parts to keep the compact excavator working well.

Match the radiator size to the hydraulic flow. Clean the radiator fins and watch the oil temperature. Flush the cooling system every year. Use the right coolant. These steps help the DK16P Mini Excavator stay strong and ready for many jobs.

Operator Comfort

Seat Adjustment

A comfy seat helps people use a mini excavator all day. The DK16P Mini Excavator has a thick, soft seat. You can adjust it with one touch. Move the seat forward or back to fit your height. The seat moves with the console, so controls stay close. This makes it easy to reach everything. Good seat position helps you sit up straight. It also helps stop back pain during long work. The cab is big, so you can stretch your legs. This keeps your legs from getting stiff. When the seat fits well, you feel less tired. You can pay better attention to your work. Adjusting the seat is a simple way to work better and avoid getting hurt.

Tip: Adjust your seat before you start working. A few seconds now can stop hours of being uncomfortable later.

Fatigue Reduction

Working long hours in a mini excavator can make you tired. Muscles can get sore and you might react slower. The DK16P Mini Excavator has smart features to help with this. It has easy-to-use joysticks, armrests, and footrests you can move. The controls are close, so you do not have to reach far. Thick glass and tight seals keep out noise and shaking. Special mounts under the cab stop the machine from shaking too much. The cab stays cool in summer and warm in winter. LED lights help you see well, even when it is dark. Wide doors and low floors make it easy to get in and out. This is helpful when you are busy.

Key ergonomic features in the DK16P Mini Excavator:

Seat and console you can adjust

Big cab with more space for your head and legs

Joystick controls that are easy to use

Mounts that cut down on shaking

Experts say these features help you stay awake and comfy. When you feel good, you take fewer breaks and make fewer mistakes. This means you get more done and do better work. A compact excavator with good design helps teams work longer and stay safe.

Jobsite Planning

Planning the jobsite helps teams use the excavator better. When the site is organized, work goes faster. Teams make fewer mistakes and get better results. Planning ahead helps finish projects quickly and with less stress.

Work Zones

Clear work zones help a lot. Crews should walk around and look for things that might slow down the excavator. They need to find pipes or tight spots. Put the excavator and materials where they are easy to reach. Make sure they are not in the way. This saves fuel and keeps the machine working longer.

Here are steps for setting up work zones:

Look for obstacles and mark safe spots.

Put the excavator near the main work area.

Keep materials and waste bins close but not blocking paths.

Make a simple schedule so everyone knows their job.

Talk with the team often to stay on track.

Follow safety rules and check the site every day.

Use GPS or software to watch progress.

Evidence of Improvement | Impact on Mini Excavator Workflow and Project Completion | |

|---|---|---|

Optimized Resource Allocation | See equipment and workers in real time | Excavators work better, downtime drops, tasks go faster |

Improved Communication and Reporting | Data is collected and shared quickly | Equipment status is shared fast, delays are avoided |

On-Time Project Delivery and Accountability | Watch schedules and progress all the time | Excavator work stays on schedule, bottlenecks are stopped |

Data-Driven Decision Making | Study work patterns and change schedules | Workflow gets better, tasks finish faster |

Material Staging

Material staging means putting supplies in the right place. When materials are close to the work zone, the excavator does not waste time moving around. This keeps the job going and helps everyone focus.

Putting materials near the work zone saves time and energy.

Waste bins close by but not blocking paths help the excavator keep working.

Less moving means less fuel used and less wear on the excavator.

Good staging helps steady work and makes switching tasks easy.

Teams avoid slowdowns and keep the project moving.

Smart planning and good staging help teams use the DK16P Mini Excavator well. This makes projects better and work smoother.

Technology

Smart technology makes the DK16P Mini Excavator special on busy sites. Operators use built-in tools to work better and make fewer mistakes. These features help every job go faster and easier.

Diagnostics

The DK16P Mini Excavator has onboard diagnostics. Operators can see machine health on clear displays. The system shows alerts for oil pressure, engine heat, and hydraulic flow. If there is a problem, the display warns right away. This helps operators fix issues before they get worse. Quick checks mean less waiting and better work. Teams spend more time working and less time trying to find problems.

Here are some features that help with efficiency:

The Kubota engine uses E-TVCS combustion technology for steady power and low emissions.

The slim body lets the mini move through tight spaces.

The cockpit rotates 360 degrees, so operators work from any angle.

The quick-attach system swaps buckets and augers fast.

The engine lasts a long time, often over 5,000 hours before overhaul.

Operators say the controls feel smooth and jobs finish faster.

These features help the compact excavator work better and last longer.

Work Modes

Selectable work modes let operators match the mini’s power to the job. They change engine speed and hydraulic flow with a simple switch. Lower modes use less fuel and keep the engine cool during warm-up or idle. Mid-range modes give precise control for lifting and digging. Higher modes deliver maximum speed for heavy-duty tasks like truck loading. Operators pick the right mode for each job. This saves fuel, reduces engine strain, and improves performance.

A table shows how work modes help:

Work Mode | RPM Range | Best For | Benefits |

|---|---|---|---|

Low | Warm-up, idle | Less fuel, less strain | |

Mid | 1,100-1,400 | Lifting, digging | Precise control, efficiency |

High | 1,500-1,800 | Heavy-duty, loading | Max speed, more power |

Operators use these modes to get the best results from the DK16P Mini Excavator. The compact excavator works smarter, not harder. Teams finish jobs faster and use less fuel. Smart technology makes every project easier.

Digging Efficiency

To get the most from the DK16P Mini Excavator, use smart digging steps. Operators who watch bucket position and make smooth moves do better work. This helps the mini excavator last longer and work well.

Bucket Position

How you place the bucket matters a lot. Experts say keep the excavator close to where you dig. This saves fuel and time. Angle the bucket between 30° and 45° when digging. This helps the mini cut through dirt easily. It also lets the machine dig deeper and faster.

Watch the stick angle too. Keep it between 35° and 45° for best results. This gives good reach and keeps the excavator steady. The DK16P’s strong hydraulics make these moves easy. When loading trucks, put them on the left side. This gives a better view and makes dumping safer.

Here is a table to help you dig better:

Tip | Result |

|---|---|

Bucket angle 30°-45° | Easier digging, less resistance |

More stability, better digging | |

Stay close to dig area | Saves fuel, less moving |

Safer dumping, better view |

Tip: Pick the right bucket for each job. Use a mud bucket for wet dirt. Use a standard bucket for most digging.

Movement Tips

Smooth moves help the mini excavator last longer. Try not to start or stop too fast. This keeps the parts from wearing out quickly. Make sure the tracks are tight to stop extra wear. The DK16P’s boom swing helps you move dirt with less effort.

Plan your moves before you start. Work from a flat, solid spot for best results. Quick couplers let you change tools fast. This saves time and keeps the mini ready for work. Check fluids and clean the excavator often to keep it working well.

Note: Talk clearly with truck drivers and your team. This stops extra moves and keeps the job going smoothly.

If you follow these tips, you can work faster, do better, and get more done with your DK16P Mini Excavator every day.

End-of-Day Routine

A good end-of-day routine helps the DK16P Mini work well. Operators who use a checklist see better results and less downtime. This routine helps the excavator last longer and keeps jobs on schedule.

Clean-Up

Operators should always clean the mini at the end of the day. Dirt and mud can hide leaks or broken parts. Cleaning the engine area helps find problems early. Wiping off mud after work stops rust and keeps the paint nice. Lubricating moving parts, like hydraulic cylinders and pivot points, stops rust and keeps things working well. Operators should fix chipped paint to stop rust and keep the mini looking good.

Here are some easy cleaning steps:

Use gentle soap to protect paint and coatings.

Keep vents, grilles, and air intakes clear to stop overheating.

Lubricate joints and cylinders before putting the mini away.

Check the mini every few weeks, even if you are not using it.

Write down cleaning and oiling in a log.

Maintenance Task | Recommended Frequency |

|---|---|

Every 8-10 hours of use | |

Replace radiator coolant | Every 2,000 hours |

Clean radiator fins | Often |

Check for leaks or blockages | Often |

Inspect hoses and clamps | Often |

Regular cleaning keeps the excavator valuable and working its best.

Shutdown

A safe shutdown gets the mini ready for tomorrow. Operators should do these steps:

Turn off the excavator.

Put the arm and boom down.

Lock the cab door.

Put the keys in a safe spot.

This routine stops accidents and keeps the mini safe at night. Operators who check fluids, grease parts, and tighten tracks at the end of the day help stop small problems from getting worse. Keeping a log helps plan repairs and track how the mini is doing.

Doing this routine every day helps the excavator work better, last longer, and stay safe. Good care can make an excavator last up to 50% longer. Teams who follow these steps get more work done, have fewer repairs, and save money. This routine keeps the excavator working and helps every project go well.

The seven Labor Day hacks help DK16P Mini Excavator users work faster and safer. These tips also help people feel less stressed while working. Doing regular maintenance keeps the machine running well. Planning ahead and using smart features help teams get more done. Jake and Maria say the controls are easy to use. They also say digging is smooth and simple. Teams notice less downtime and save more fuel, sometimes up to 30%.

User Type | Project | Result |

|---|---|---|

Contractor | Trenching | Finished quickly, no breakdowns |

Landscaper | Garden beds | Easy controls, simple moving |

City Crew | Sidewalk repair | Fast work, little damage |

Homeowner | Pond digging | Simple to use, saves fuel |

If you want more tips or details, check out DeepKron’s website. You can learn about the DK16P Mini Excavator and see how it can help with your next job.

FAQ

How much weight can the DK16P Mini Excavator lift?

The DK16P Mini Excavator can lift up to 1,600 kg (about 3,500 pounds). This makes it strong enough for most digging, lifting, and loading jobs on small to medium sites.

What kind of fuel does the DK16P use?

This mini excavator runs on gasoline. The engine comes from Briggs & Stratton and delivers 13.5 horsepower. Operators find it easy to refuel and maintain.

Can one person change attachments by themselves?

Yes! The DK16P’s quick-attach system lets one person swap attachments in just a few minutes. No extra tools or help needed. This saves time and keeps work moving.

How often should operators check the tracks?

Operators should check the tracks every day before starting work. Daily checks help spot damage, dirt, or loose parts early. This keeps the excavator safe and running smoothly.

Does DeepKron offer a warranty for the DK16P?

DeepKron covers the DK16P with a 12-month or 1,000-hour warranty. This warranty protects against defects in materials and workmanship. For more details, visit the DeepKron website.