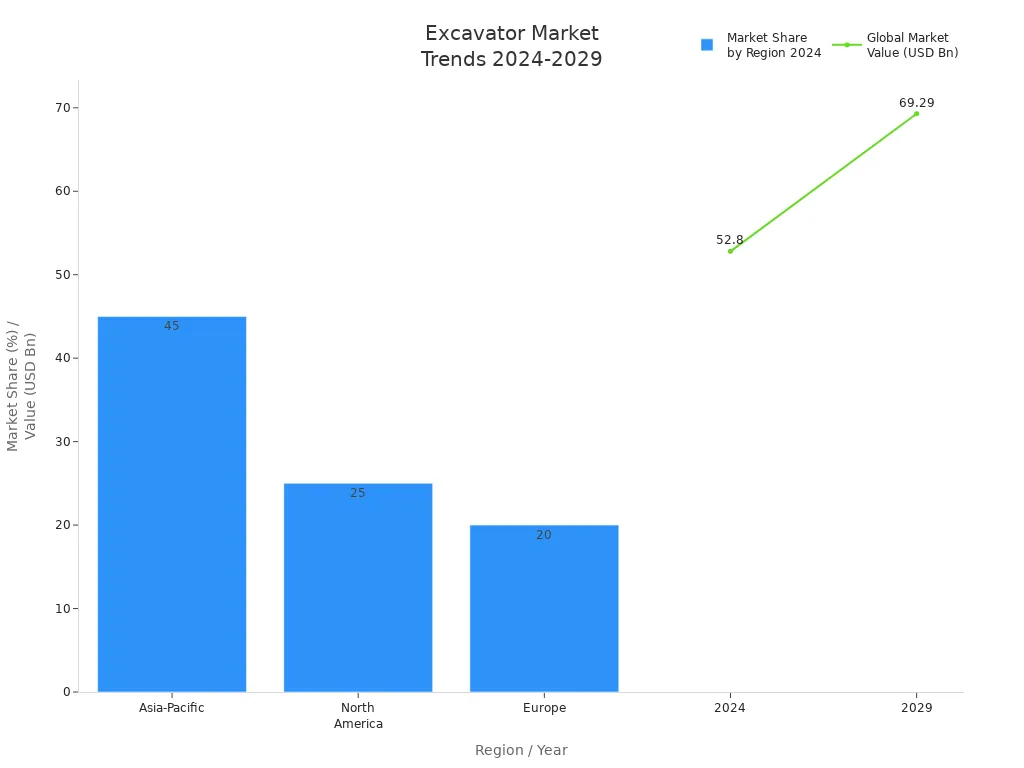

Innovation brings fast changes to construction equipment, and leading excavator manufacturers are now incorporating automation, electric models, and telematics. These advancements help work get done faster and better. Market data shows Asia-Pacific holds the largest share at 45%. Mini excavators are gaining popularity worldwide.

DeepKron, one of the trusted excavator manufacturers, is known for small machines that are strong and flexible.

The DK16P mini excavator is easy to use and works well in tight spaces.

Customers prefer DeepKron because its machines are easy to maintain and effectively solve real problems.

Region | Market Share 2024 | Key Growth Drivers and Trends |

|---|---|---|

Asia-Pacific | 45% | Fast growth with 30% CAGR driven by urban expansion, new roads, and increased mining activities in China and India. |

North America | 25% | Growth fueled by rising rentals, automation adoption, and infrastructure projects like new roads and bridges. |

Europe | 20% | Emphasis on green building practices and energy-saving initiatives. |

Technological Advancements

Excavator manufacturers are always trying new technology. They want machines to work better, safer, and faster. DeepKron adds new features to its small machines. This helps customers get the newest technology.

AI and Automation

AI has changed how excavators work on job sites. In 2025, AI tools are now used every day. Robots can dig with little help from people. These robots check their own health and plan work schedules. They also give real-time data to workers. AI systems warn about problems early and suggest fixes. Virtual wall technology keeps the arm and bucket in safe areas. This protects people and property.

Robotic excavators use sensors and machine learning to work very accurately. They can work all day and night. This means more work gets done and costs go down. Automation keeps people away from dangerous jobs. This makes job sites safer and lowers accidents.

The table below shows important AI technologies in today’s excavators:

AI-Driven Technology | Description | Benefits |

|---|---|---|

Autonomous Digging | Excavators perform tasks automatically using AI algorithms. | Increases productivity, lowers labor costs. |

AI Monitoring Systems | Monitors equipment condition and predicts faults. | Minimizes downtime, improves reliability. |

Virtual Wall Technology | Limits movement to safe zones. | Enhances safety, especially in tight spaces. |

Onboard Weighing | Measures load in real time. | Prevents overloading, ensures compliance. |

Lift-Assist Mode | Monitors load weight and alerts for overloading. | Prevents tipping, improves safety. |

Augmented Reality (AR) | Provides enhanced visualization for operators. | Improves control, reduces learning curve. |

Machine learning can watch site videos and spot activities. This helps check work and make things run better. It also means less time spent watching by hand.

IoT and Connectivity

IoT and telematics are now key in excavators. IoT telematics collect data on machine health and fuel use. They also track how operators use the machines. Technicians can fix problems from far away. This means less downtime. Geo-fencing and alarms stop theft and misuse.

IoT helps plan repairs before machines break down.

Real-time checks keep excavators working longer.

AI and IoT sensors help spot problems and make smart choices.

A company in the Netherlands put IoT in over 100 machines. The system found problems early. This stopped big breakdowns for a whole year. The company saved time and made their machines more reliable.

AR and Operator Assistance

AR and operator help systems are changing how people use machines. AR puts digital info over real life. It shows digging depth, machine spot, and obstacles. Smart goggles and tablets give tips in real time. This makes training and safety better.

AR helps with repairs and safety checks by showing 3D images.

AR training puts students in real-life situations.

AR lets many people train at once and gives feedback.

These tools help people see dangers and avoid accidents. Both new and old operators learn skills and get ready for tough jobs.

Onboard Weighing and Grade Assist

Onboard weighing and grade assist are big steps forward. Sensors check material weight as you load. This stops trucks from being too full or too empty. Grade assist moves the boom and stick for more accurate cuts.

Onboard weighing helps load trucks just right and saves money.

Grade assist shows how deep or steep to dig.

Automated controls make grading faster and easier.

Lift assist checks bucket weight and warns if tipping is possible.

DeepKron puts these features in its small excavators. Grade assist uses sensors and settings from the operator. Onboard weighing uses load cells to check weight. These tools help everyone do better work, waste less, and keep the job site safe.

More people are using these systems because they save fuel, boost safety, and get more work done. DeepKron keeps adding new technology so customers always have the best compact machines.

Sustainability

Electric and Hybrid Excavators

Excavator makers want cleaner machines now. The electric excavator is leading this change. It does not make emissions when it works. This helps lower pollution and keeps the air cleaner. Many companies use electric excavators in cities because they are quieter than diesel ones. For example, a test with a Volvo electric excavator showed 64% less carbon emissions and 74% lower hourly costs. Electric motors also need less fixing, so machines stop working less often.

Aspect | Diesel Excavators | Electric/Hybrid Excavators |

|---|---|---|

Carbon Emissions | Baseline | |

Hourly Costs | Baseline | 74% lower |

Noise Level | High | Much quieter |

Maintenance | High | Lower |

DeepKron keeps making new electric excavator models. These machines help builders save money and follow new green rules.

Green Manufacturing

Makers now use green ways to build excavators. They pick recycled and plant-based materials to help the planet. DeepKron and other top brands use modular designs and smart tech to make factories work better. They also use telematics to watch machine use and plan repairs. This cuts waste and saves energy. Many companies work with energy storage and hydrogen groups to make zero-emission excavators. These steps help meet tough rules like the EU Green Deal.

Green manufacturing means safer job sites, less pollution, and better results for all.

Recycled Materials

Excavator makers use more recycled materials in their machines. They choose local and earth-friendly parts when they can. This means less need for new stuff and less waste. DeepKron uses recycled steel and plastics in its small excavators. These choices help the planet and support a circular economy. Customers now want machines that are strong and good for the environment.

Operator Safety

Ergonomics and Comfort

Modern excavators have cabs that are bigger and more comfortable. Operators get more space for their heads and legs. Seats can be changed with one touch to fit the person. The seats move with the console for easy changes. Controls are placed so they are easy to reach. Thick glass and tight seals help block noise and shaking. Special mounts also help stop vibration. Air systems keep the cab cool or warm in any season. Operators can adjust armrests, footrests, and joysticks. Bluetooth radios and hands-free calls make work easier. LED lights help operators see better. Wide doors and low floors make it easy to get in and out. These changes help operators feel less tired and stay focused. This makes job sites safer and helps people work better.

Camera and Sensor Systems

Excavators now use cameras and sensors to keep people safe. AVM camera systems let operators see all around the machine. This helps stop crashes with people or things nearby. Sensors use sound and lights to warn about close objects. Cameras and sensors help operators see better in the dark or when things block their view. Operators can work faster and feel more sure of themselves. This means fewer accidents and less damage to machines. It also saves money on repairs.

Safety Automation

New excavators have safety automation to protect everyone. Over-dig protection stops digging too deep or too far. This saves materials and keeps machines from breaking. Virtual fences make a safe area around the machine. The machine will not move close to danger. Cab avoidance and 2D E-Fence stop the machine near unsafe spots. Smart controls help move the boom and bucket safely. Zero tailswing keeps the machine inside its own space. This is good for small work areas. Warnings with sounds and lights tell operators when they get close to limits. These features help operators make fewer mistakes and stay safe. Everyone on the job site is safer because of these new tools.

Customization

Attachments and Modularity

Excavator manufacturers now give many attachment choices. These options help machines do more jobs at each site. Operators can change tools fast, so machines are more useful. In 2025, buckets, hammers, grapples, and thumbs are the most used. These attachments help with demolition, recycling, forestry, and digging.

Steelwrist’s SQ40 automatic coupler lets operators switch tools from inside the cab. This keeps workers safe and saves time.

Tiltrotators and new coupler systems make digging and grading easier.

iDig’s 2D and 3D guidance systems use wireless sensors and screens in the cab. These help operators dig more accurately.

Zquip’s electric and diesel power modules can be swapped. Users pick the best power for each job.

Hyundai’s electric and hydrogen excavators show how modular power helps with utility and being green.

Manufacturers also make smart attachments with sensors and telematics. These tools check how well they work and help with repairs. Quiet and eco-friendly attachments follow new rules and work well in cities. Modular and multi-use attachments are now needed for jobs that need flexibility.

Tailored Solutions

Manufacturers create special solutions for each industry’s needs. They work closely with suppliers to give fast, reliable service and custom machines. Strong materials like hardened alloy steel and heat-treated cast iron make machines last longer and stay safe on tough jobs.

Industry | Tailored Use Cases | Specialized Features and Benefits |

|---|---|---|

Construction | Foundations, demolition, handling | High power, reliability, efficiency |

Mining | Overburden removal, extraction | Durability, stability, utility in tough sites |

Land Development | Clearing, pond digging, prep work | Versatility, efficiency, utility for all tasks |

Agriculture | Irrigation, grading, planting | Power, efficiency, utility for farm work |

Waste Management | Sorting, handling, removal | Reliability, utility for heavy waste |

Forestry | Harvesting, clearing, road building | Durability, utility with special attachments |

Manufacturers now add GPS grading, telematics, and IoT to make machines work better. Electric and hybrid models help with green goals. Lighter and smaller designs make moving and using machines easier for everyone.

Market Trends for Excavator Manufacturers

Mini Excavator Demand

Mini excavators are becoming more popular each year. Cities are growing fast, especially in Asia-Pacific. This makes more people want small excavators for building projects. These machines work well in small spaces and can do careful jobs. In 2024, the mini excavator market was worth over $10 billion. Experts think this number will keep going up. Companies are making better hydraulic systems and engines that use less fuel. DeepKron is a top brand that sells strong and dependable small machines all over the world. Mini excavators are now important for landscaping, farming, and utility jobs. This shows how the market is changing.

Supply Chain Resilience

Excavator makers have problems getting parts they need. Trade fights, sickness outbreaks, and missing parts like semiconductors slow down building. To fix this, companies buy from more suppliers and build things closer to home. Many use computers to watch shipments and guess what might go wrong. These steps help keep machines in stock and prices steady. Some companies also change their designs to follow new green rules. This can make things take longer. DeepKron’s worldwide network helps them deliver machines on time, even when things are tough.

Digital Transformation

Digital tools are changing how excavators are made and used. Makers use telematics and AI to check machine health and plan repairs. Real-time data helps machines work better and break down less. People now want smart machines that are safe and save time. DeepKron puts these new digital tools in its small excavators. This makes them a leader in the industry. These changes help companies stay ahead and give customers what they need.

Challenges and Opportunities

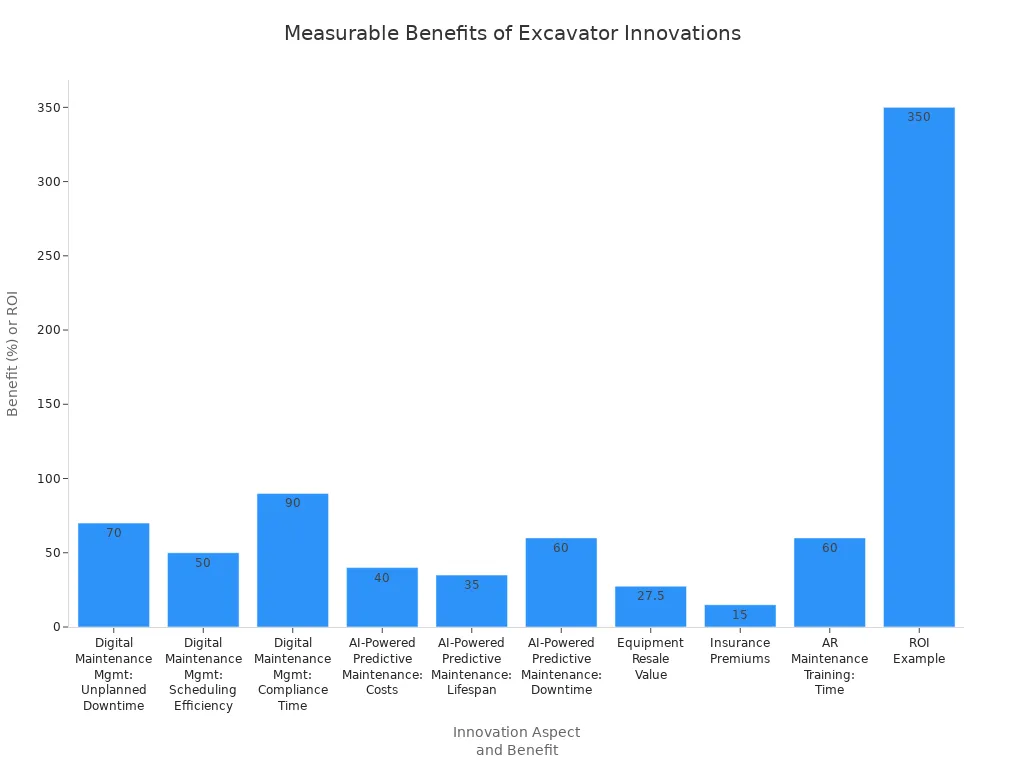

Costs and ROI

Excavator makers have many costs to think about. These costs change how much money they and buyers can make. Picking the right machine size and reach saves money. The tail swing type can change safety and repair bills. How well hydraulics and engines work affects fuel use and what tools you can use. Telematics and GPS help keep machines running and lower downtime. This helps people get more value from their machines. Buyers must pick between new or used machines. Each choice has its own price and benefits. Loans and leases change how much money you spend now and later.

Cost Component | Description | Impact on ROI |

|---|---|---|

Interest on Financing | Different interest rates change the total cost of buying. | Higher interest means you pay more, so you make less money. |

Taxes | You pay sales tax when you buy; some tax rules can save money. | Good tax planning helps you keep more cash and make more money. |

Insurance | Insurance is about 2% of the machine’s price each year. | Insurance keeps your machine safe but adds to your bills, so you make less. |

Fuel Consumption | Fuel cost depends on size, hours used, and tools. Example: $20 for 4 hours. | Using less fuel saves money and helps you earn more. |

Maintenance | Regular oiling and checks stop big repairs. | Good care means less downtime and fewer repairs, so you make more. |

Attachments | Extra tools cost more to buy and use. | Attachments help do more jobs but also cost more, so you must use them well to make money. |

Regulations

New rules in 2025 bring both problems and chances for makers. The U.S. now has a 10% import tax on all goods. Some countries pay even more. These taxes make imported machines cost more. Companies may need to build machines in new places. Stricter rules on pollution and noise mean more electric and hybrid machines. Emissions rules like EU Stage V and U.S. EPA Tier 4 Final are very strict. Machines must be cleaner to pass these rules. Safety rules now need things like roll-over protection and operator checks. These changes make machines safer and cleaner. But they also make machines cost more and can change how much they sell for later.

Emerging Markets

New markets are growing fast for construction equipment. Asia Pacific is growing quickly with new cities and big projects in China and India. Countries like South Korea, Thailand, and Vietnam also want more new machines. Southeast Asia and Latin America are building roads, trains, and mines. This makes more people buy small excavators and special tools. Local rules ask for more electric and hybrid machines. Makers work with local partners to bring new tech to these fast-growing places. Governments help by making new laws and giving support. This makes more people want modern construction equipment.

Latest Technologies Fueling Excavator Evolution

Technological Advancements in Track Excavators

Track excavators have changed a lot in 2025. Makers now add new technology to help track excavators work better. These changes make jobs faster and safer. Operators can finish work with fewer mistakes.

GPS, satellite, and laser systems help with grading. Operators use joysticks and touchscreens to control the arm. Machines can grade in 2D or 3D modes. Laser receivers can be adjusted to stop digging too much and save time.

Smart sensors and brakes keep the arm steady. These features help hold loads safely, even when moving fast.

Virtual wall technology sets safe limits for the bucket and arm. This stops accidents in small spaces and keeps people and property safe.

Onboard weighing checks loads right away. The system warns if the ground is not flat or the load is too heavy.

Lift-assist mode checks each lift’s weight. Alarms warn before tipping or damage can happen.

Automation and AI let machines dig by themselves. AI systems watch the machine and help it work longer.

AR gives operators extra information. AR glasses or headsets show digging depth, machine spot, and warnings. This helps people learn faster and control the machine better.

These new technologies have changed how teams work. Electric and hybrid power cut emissions by up to 90%. Hybrid machines use braking to save fuel and work better. GPS and 3D modeling help make work more exact. This cuts waste and saves up to 30% of time. Telemetry and data help plan repairs and keep machines working. Remote controls let workers use excavators from far away in dangerous places. Fully automated excavators use AI and robots to do more work and make fewer mistakes. Using recycled materials and special attachments helps the environment by letting teams reuse things on site.

These new technologies help operators follow rules and meet market needs. They also make job sites safer and help work get done faster.

Technology | Benefit | Impact on Track Excavators |

|---|---|---|

GPS & Laser Grading | Accurate cuts, less rework | Faster, more precise excavation |

Virtual Wall | Prevents overreach, protects surroundings | Safer operation in tight spaces |

Onboard Weighing | Real-time load checks | Safer, compliant material handling |

AR Visualization | Enhanced operator awareness | Easier training, fewer mistakes |

Electric/Hybrid Power | Lower emissions, less fuel | Greener, cost-saving operation |

Telemetry/Data Analytics | Predictive maintenance, fleet optimization | Less downtime, higher efficiency |

DeepKron’s Innovative Solutions

DeepKron is a leader in making small machines better. The company puts the newest technology in every model. DeepKron’s track excavators have grading help, virtual wall technology, and onboard weighing. These features help operators do careful work and avoid mistakes.

DeepKron uses electric and hybrid power to lower emissions and costs. Its track excavators have smart sensors and AI systems. These tools check machine health and tell when repairs are needed. Operators get alerts right away, so they can stop breakdowns and finish jobs on time.

DeepKron also uses AR to help operators. Operators wear AR headsets to see digging depth, machine spot, and dangers. This makes training faster and keeps job sites safer. The company’s attachments and quick couplers let users change tools fast. This makes each track excavator good for many jobs.

DeepKron’s focus on new ideas means every customer gets the best technology. The company’s new track excavator technology helps businesses stay ahead in a changing world.

DeepKron also uses recycled materials in its track excavators. The company designs machines that are easy to fix and last a long time. These changes help the planet and help businesses do well.

In 2025, DeepKron keeps leading with the latest technology for excavators. The brand’s focus on quality, efficiency, and happy customers makes it a top pick for contractors everywhere.

New excavator technology helps both makers and users. These changes bring real improvements for everyone. The table below shows the main benefits:

Innovation Aspect | Measurable Benefit | Impact |

|---|---|---|

Digital Maintenance | Lower costs, better reliability | |

AI Predictive Maintenance | 40% lower maintenance costs | Longer equipment lifespan |

Autonomous Operation | Improved safety, efficiency | Fewer accidents, higher output |

Using new excavator technology helps businesses grow. It also helps companies make more money and follow rules. DeepKron’s new ideas help buyers stay ahead of others. Watching new trends helps companies stay strong in the market.