Welcome to using a mini excavator! You can learn to use an excavator safely. You do not need any experience. Knowing safe ways to work and how to use the controls keeps everyone safe.

Accident reports show that not having operator training can cause bad accidents. Safety training before starting helps lower these risks.

In 2019, about 20% of worker deaths were in construction. This is why safety rules are important.

15% of accidents on sites happened from loading things the wrong way. This shows you must know how to load things right.

Operators who learn advanced excavator skills can work up to 20% faster.

If you practice often and follow safety rules, you can get good at using a mini excavator. You can use it for many different jobs.

Key Takeaways

Always check your mini excavator every day for safety. This helps you find problems early. It also keeps the machine working well.

Use both hands on the joysticks when you drive. Move the controls slowly and carefully. This helps you stay safe and avoid accidents.

Wear all the safety gear you need. Always wear your seatbelt. This keeps you safe from getting hurt while you work.

Get the right training and certification before you use a mini excavator. This helps you learn how to use it safely. It also lowers the chance of accidents.

Keep learning and practicing often. This helps you get better at using the machine. It also helps you stay safe at work.

Mini Excavator Controls

Operator’s Station

When you sit in the operator’s station, you see many controls. The seat can move so you feel comfortable. There are armrests and climate controls to help you focus. Some excavators have LCD screens that show machine details. You can use these screens to change settings. These features help you stay safe and comfortable while working.

Key Controls

You use hand joysticks to control the mini excavator. The left and right joysticks move the boom, dipper, and bucket. Some machines have foot pedals too, but most people like hand controls better. Hand controls are easier and help you move smoothly. They also help you not get tired as fast. This is helpful when you work in small spaces. Thumb switches on the joysticks let you control attachments. This makes your job easier.

Tip: Always use both hands on the joysticks. This gives you more control. It helps you avoid quick or rough movements.

ISO vs. SAE Patterns

Mini excavator controls use two main patterns: ISO and SAE. These patterns decide what each joystick does. The table below shows how they are different:

Control Pattern | Left-hand Lever Functions | Right-hand Lever Functions |

|---|---|---|

ISO | Toward you: Bring dipper toward you | Toward you: Raise the boom |

Away from you: Extend dipper away | Away from you: Lower the boom | |

Left: Swing left | Left: Curl bucket in (close) | |

Right: Swing right | Right: Curl bucket out (dump materials) | |

SAE | Toward you: Raise the boom | Toward you: Bring dipper toward you |

Away from you: Lower the boom | Away from you: Extend dipper away | |

Left: Swing left | Left: Curl bucket in (close) | |

Right: Swing right | Right: Curl bucket out (dump materials) |

Some people find it hard to switch between ISO and SAE. This is because the joystick jobs change. Directional compatibility helps your hands match the machine’s moves. This makes using the excavator easier.

Control Switching

Many mini excavators let you change between ISO and SAE. You can do this with a button or on the LCD screen. This lets you use the pattern you know best. Easy switching helps you work better and feel more comfortable. Studies show that good control switching can help you work faster and save fuel. Always check which pattern your machine uses before you start.

Safe Operation Techniques

Pre-Start Checklist

Check the mini excavator before you use it. A checklist helps you find problems early. This keeps you and others safe. Always use a safety checklist before each shift. The checklist helps you see damage, leaks, or other problems. These issues can cause accidents or breakdowns.

Walk around the mini excavator. Look for dents, cracks, or bends on the body, undercarriage, and tracks.

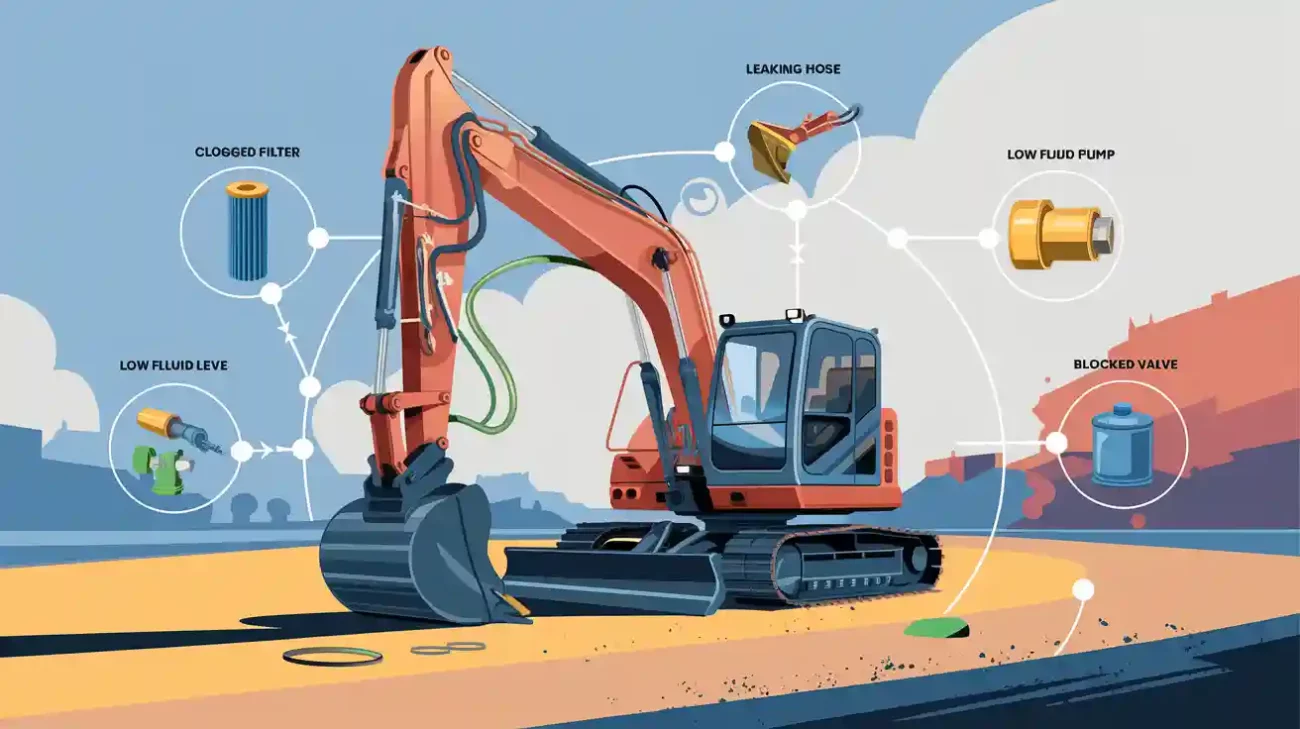

Check all fluid levels like oil, coolant, and hydraulic fluids. Low fluids can make the machine stop working.

Look at the hydraulic system. Check the pump, cylinders, lines, and hoses for leaks or damage.

Check the bucket and attachments. Look for broken teeth or uneven wear.

Make sure the horn, lights, and backup alarm work.

Test the controls to see if they work smoothly.

Read the operator’s manual for special instructions.

Write down your inspections. This helps you remember the excavator’s condition and follow OSHA rules.

Tip: Use a printed or digital checklist every day. This helps you remember each step and keeps your checks the same.

Checking the mini excavator often helps you stop breakdowns. Many companies save money by doing this. You can keep your equipment ready and in good shape by using a daily checklist.

Starting and Stopping

You need to follow steps to start and stop the mini excavator safely. These steps help you avoid accidents and protect the machine.

To start the mini excavator:

Use the handholds and steps to get in the cab.

Sit down and put on your seatbelt.

Make sure the safety lock lever is locked.

Put the key in and turn it to “on.” Wait for the warning lights to turn off.

Move the safety lock lever to “operate.”

Start the engine and let it warm up.

To stop the mini excavator:

Lower the bucket and attachments to the ground.

Lock the safety lock lever.

Let the engine idle for a minute.

Turn off the engine and take out the key.

Get out of the cab carefully.

Always do these steps to stay safe and keep the machine working well.

Maneuvering

Move the mini excavator carefully, especially in small spaces or on hills. Use the controls gently to stop sudden moves. Keep the machine steady by moving slowly and keeping the boom and bucket low.

Use both joysticks for smooth and safe operation techniques.

Watch for people and things around you.

Slow down when turning and do not make sharp turns.

On hills, keep the heavy end uphill. Go straight up or down, not sideways, to stay stable.

Using the controls smoothly is important for safety. Studies show that good control helps keep the machine safe during jobs like leveling. You can get better by practicing slow, steady moves.

Digging Techniques

Digging is a main job for a mini excavator. You need to use the right ways to dig safely and well.

Put the excavator on flat, strong ground.

Lower the blade to make it more stable.

Use the boom and dipper to reach the spot you want to dig.

Curl the bucket to scoop up dirt.

Lift the bucket and swing it to where you want to dump.

Dump the dirt by uncurling the bucket.

Move slowly and do not jerk the controls. Fast moves can make the excavator tip. Always check the ground for dangers before digging. Good digging helps you work faster and keeps the site safe.

Backfilling and Grading

Backfilling and grading need careful control to keep the ground even and the machine steady.

Use the blade to push dirt back into the hole or trench.

Keep the bucket low and move slowly.

For grading, use the bucket edge to smooth the ground.

Check your work often to keep the ground level.

Watch for soft or uneven ground. These can make the excavator tip or lose balance. Smooth and safe operation techniques help you finish the job without accidents.

Operation Tips

Here are some safety tips to help you work safely and well:

Always wear your seatbelt and safety gear.

Keep your hands on the controls and pay attention.

Do not overload the bucket or attachments.

Stay away from the edge of trenches or hills.

Talk to other workers and use signals when needed.

Follow all safety rules and best ways to work.

You can keep your mini excavator ready by following these tips and practicing every day. Good habits and regular checks keep you, your team, and your mini excavator safe.

Mini Excavator Safety

Pre-Operation Checks

You should always begin your day with a safety check. This helps you spot problems before they get worse. Walk around the mini excavator and look for leaks or cracks. Check for loose parts too. Look at the tracks and undercarriage for any damage. Test all the lights, alarms, and horn to see if they work. Make sure the seatbelt clicks and holds tight. Use a checklist so you do not forget anything you check.

Tip: A safety checklist helps you remember each step and keeps your mini excavator working well.

Try out the controls before you start working. Move the joysticks and pedals to see if they work right. If something feels wrong, stop and tell someone. Doing these checks lowers the chance of accidents and keeps everyone safe.

PPE and Seatbelt Use

Personal protective equipment, or PPE, keeps you safe from many dangers. You should always wear a hard hat, safety glasses, gloves, and steel-toed boots. These protect you from things that fall, sharp edges, and flying dirt. High-visibility vests help others see you near the machine.

Never forget your seatbelt. The seatbelt is a very important safety part in every mini excavator. It keeps you inside if the machine tips or stops fast. Reports show not wearing a seatbelt makes it more likely you will get hurt. Always buckle up before you start the engine.

Common Mistakes

Many accidents happen because of simple mistakes. You can avoid these if you learn from what others did wrong. Here are some common errors:

Not checking slopes can make the machine roll over. Always look at the ground first.

Not keeping a clear view can cause you to hit someone. Watch out for blind spots.

Getting on or off the wrong way can make you fall. Always use three points of contact.

Not using seatbelts makes rollovers more dangerous.

Skipping checks before work can let problems go unnoticed.

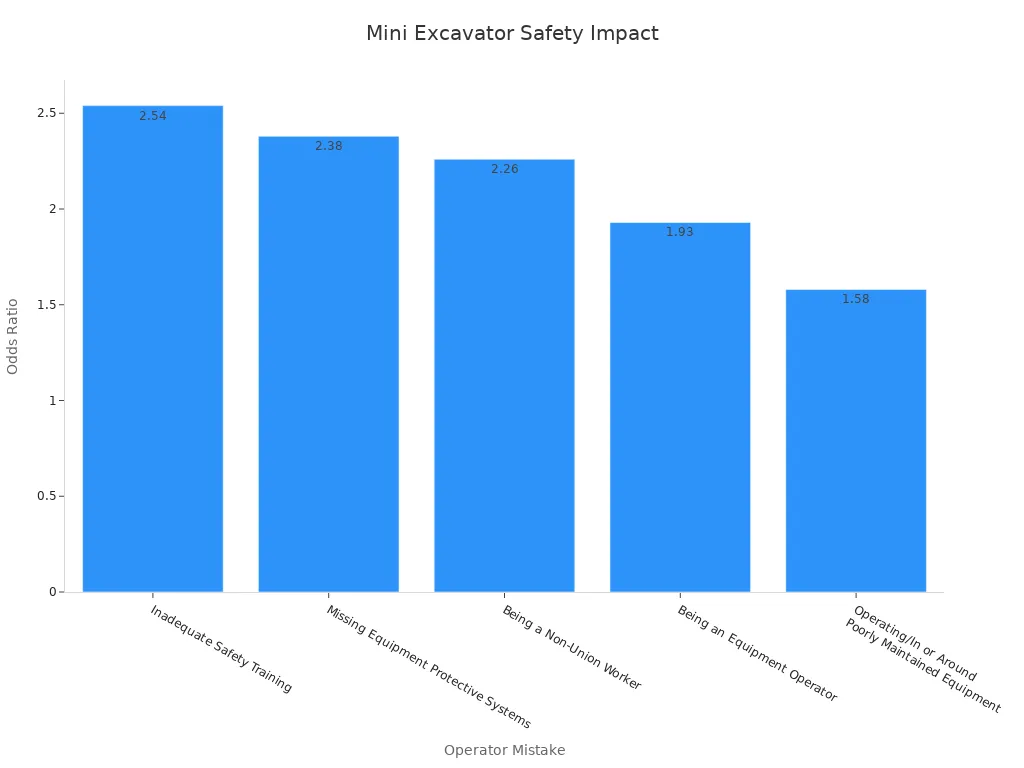

The table below shows how these mistakes can affect safety:

Operator Mistake / Factor | Odds Ratio (Fatality Risk) | Description / Impact Summary |

|---|---|---|

Inadequate Safety Training | 2.54 | Increases odds of fatality by 2.54 times; a major contributor to accident severity in mini excavator operations. |

Missing Equipment Protective Systems | 2.38 | Raises fatality odds by 2.38 times; includes missing seatbelts and malfunctioning alarms. |

Being a Non-Union Worker | 2.26 | Associated with higher fatality risk, indicating possible training or oversight gaps. |

Being an Equipment Operator | 1.93 | Operators have higher fatality odds compared to on-foot workers, highlighting operator-related risks. |

Operating/In or Around Poorly Maintained Equipment | 1.58 | Increases fatality risk due to equipment failures or hazards. |

You can see that missing training and skipping safety steps make accidents more likely. Always follow safety rules and use all the safety features.

Safety Features

Modern mini excavators have many important safety features. These help you stay safe and avoid danger. Here are some features to check:

Seatbelts and rollover protection systems keep you safe if the machine tips.

Alarms and backup beepers warn others when you move.

Lights help you see and let others see you.

Safety lock levers stop the controls from moving by accident.

Emergency stop buttons let you turn off the machine fast.

You should test these features during your safety check. Make sure alarms sound, lights turn on, and the seatbelt locks. If something does not work, do not use the machine until it is fixed.

Note: Regular checks and maintenance keep safety features working and lower risks.

Worksite Safety

Worksite safety depends on good habits and clear talking. You should set up barriers to keep people away from the swing area. Only trained workers should go into the work zone. Use hand signals or radios to talk with your team, especially when it is loud.

Keep the area around the excavator free of tools and trash. Always know where other workers are before you move. Follow safe digging steps to avoid hitting things underground. Make sure your mini excavator is right for the job and the ground.

Studies show that good worksite safety lowers accidents. OSHA data shows that sites with strong safety plans have fewer problems. Training, planning, and safety drills help everyone stay ready for emergencies.

Safety tips for operators: Stay alert, use your checklist, and never rush. Good safety habits protect you and your team every day.

Excavator Training and Certification

Certification Needs

Most job sites want you to have certification before using a mini excavator. Certification shows you know how to use the machine safely. Employers and safety groups need you to finish a training program. You must pass a written test and a hands-on test. These tests show you have the right skills. Certification also checks if you are healthy and know what to do. This helps you work safely and lowers accident risks.

Note: Certification is more than a rule. It keeps you and your team safe by making sure you know safety, controls, and what to do in emergencies.

Training Resources

There are many ways to get training for mini excavator operators. These programs follow OSHA rules and teach safety and how to spot dangers. Some classes are online, and some are in person with practice. Many courses use games and real-life practice. You will learn about the machine, how to use the controls, and how to work in different places. Programs like EcoOperator Advanced show trained operators use less fuel and save money on parts. Training mixes lessons, practice, and checks to help you keep your skills strong.

Here are some places to find training:

Local trade schools and community colleges

Online training websites

Training from the machine maker

Training and certification from your job

Ongoing Learning

You should keep learning after you get certified. Refresher classes, new tech, and accident stories help you stay up to date. More training teaches you new safety rules and better ways to use the excavator. You can join practice drills and work with a trainer to turn lessons into real skills. Good training includes learning on the job, skill checks, and safety drills. This helps you be responsible and stops accidents.

Tip: Make learning all the time a habit. It keeps you safe, skilled, and ready for anything at work.

You can get good at using a mini excavator by following steps. Practice a lot and always think about safety. Training teaches you how to use the excavator carefully. You learn to move it smoothly and find problems early. You also learn to check the equipment and follow the rules. This helps keep your worksite safe. When you practice with the machine, you feel more sure of yourself. Using safe ways every day keeps you and your team safe. Keep learning new things and enjoy being a skilled and safe operator.

FAQ

How do you get mini excavator certification?

You have to join a training class. In the class, you learn how to use the machine safely. After learning, you take a test. The test checks what you know and what you can do. If you pass, you get your certification.

Why is certification important for mini excavator operators?

Certification shows you can use the mini excavator safely. Many job sites want you to have it. It helps lower the chance of accidents. Certification also means you know the safety rules. Employers trust people with certification more.

How long does mini excavator certification last?

Most certifications are good for three years. You must renew it before it ends. To renew, you usually take a refresher class. This helps you remember safety and skills. Always look at your certification date.

Can you operate a mini excavator without certification?

You should not use a mini excavator without certification. Most jobs and sites ask for it. Certification keeps you and others safe. It also helps you follow the rules. Always get certified before you start working.

What happens if your certification expires?

If your certification runs out, you cannot use a mini excavator at most jobs. You need to take a new class or refresher course. Renewing your certification keeps you safe and legal. Always check if your certification is still good.