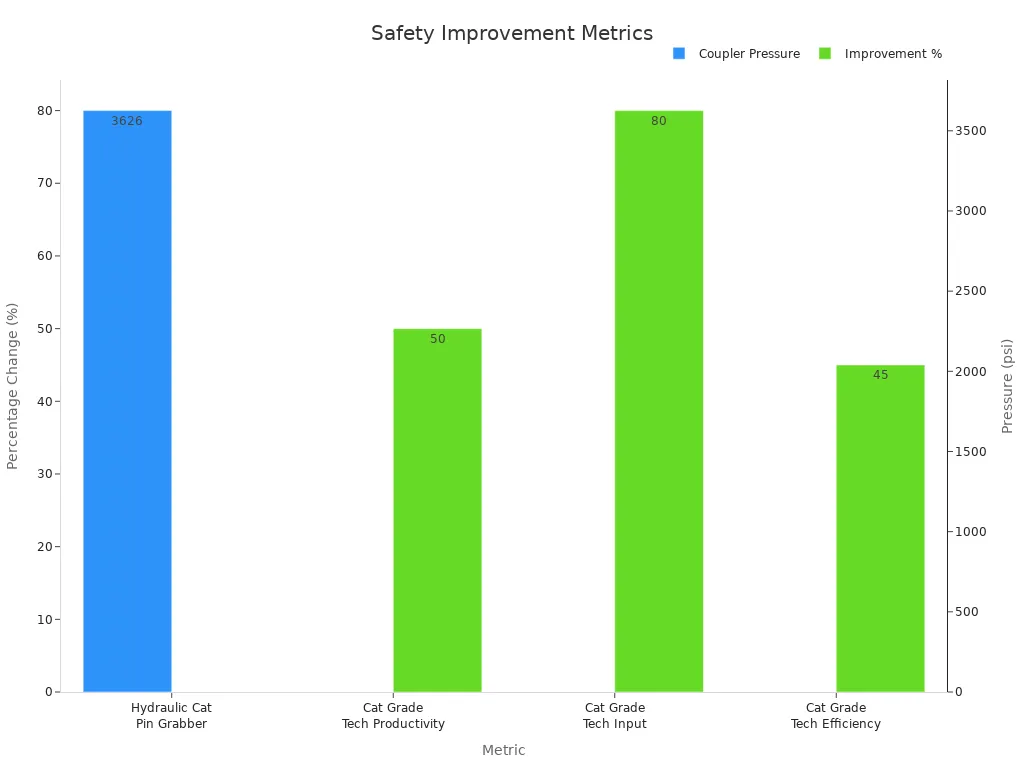

You improve safety and efficiency when you choose the right mini excavator attachments for each task. Many types of excavator attachments, such as a bucket, auger, or breaker, help with digging and handling different materials. The table below shows how selecting attachments for your excavator boosts safety:

Metric / Feature | Numerical Data / Percentage | Safety Improvement Explanation |

|---|---|---|

Hydraulic Cat Pin Grabber Coupler | Operating pressure: 3626 psi | Enables fast, safe attachment changes reducing physical intervention and downtime. |

Cat Grade Technology – Productivity | Up to 50% increase | Allows operators to work faster and more precisely, reducing errors and safety risks. |

Cat Grade Technology – Operator Input | Up to 80% reduction | Less operator effort reduces fatigue and potential for mistakes, enhancing safety. |

Cat Grade Technology – Operator Efficiency | Up to 45% increase | Improves precision and speed, lowering risk of accidents and rework. |

Use of Hydraulic Couplers | Majority of mid-size to large excavators equipped | Replaces pin-on buckets which are time/labor intensive and present safety hazards; hydraulic couplers improve safe, quick attachment changes. |

Key Takeaways

Choosing the right mini excavator attachments boosts safety and efficiency by reducing operator effort, speeding up tasks, and minimizing errors.

Different attachments serve specific jobs—buckets for digging, augers for drilling, breakers for demolition, and grapples for material handling—helping you tackle diverse projects effectively.

Regular inspection and maintenance of attachments prevent breakdowns, extend equipment life, and create a safer work environment.

Types of Excavator Attachments

Mini excavator attachments expand the versatility of your machine, allowing you to tackle a wide range of tasks with precision and efficiency. Below, you’ll find an overview of the most common types of excavator attachments and their applications.

Buckets

Buckets are the most widely used mini excavator attachments. They come in various types, each designed for specific tasks:

Standard digging buckets: Ideal for general-purpose digging in soft to medium soil. These are your go-to tools for excavation and trenching bucket tasks.

Digging and grading buckets: These combine digging capabilities with a wider edge for leveling and grading surfaces.

Specialty bucket attachments: Rock buckets, trenching buckets, and cleanup buckets are tailored for specific materials or environments.

Buckets are essential for digging, grading, and material handling. Their reinforced edges and high-strength steel construction ensure durability, even in tough conditions.

Augers

Augers are perfect for drilling holes in the ground. Whether you’re installing fence posts, planting trees, or setting up utility poles, augers make the job quick and precise. They come in various diameters to suit different project needs. Hydraulic-powered augers provide consistent torque, making them effective in hard or rocky soil.

Hydraulic Breakers

Hydraulic breakers, also known as hammers, are designed for breaking through tough materials like concrete, asphalt, and rock. These attachments are essential for demolition projects and roadwork. Their high-impact force allows you to remove obstacles efficiently, saving time and labor.

Grapples

A grapple is a versatile attachment for handling irregularly shaped materials like logs, rocks, and debris. Grapples are commonly used in forestry, construction, and waste management. A grapple bucket combines the functionality of a bucket with the gripping power of a grapple, making it ideal for clearing and sorting materials.

Thumbs

Thumb attachments enhance the gripping ability of your excavator. They work in tandem with buckets or grapples to secure materials during lifting and moving. Thumbs are especially useful for handling large or awkward objects, such as tree stumps or scrap metal.

Rippers

Rippers are designed to break up hard soil, frozen ground, or compacted materials. These attachments are perfect for preparing sites for excavation or loosening materials before digging. Their sharp, pointed design allows them to penetrate tough surfaces with ease.

Compactors

Compactors are used to compress soil, gravel, or asphalt, ensuring a stable foundation for construction projects. These attachments are essential for roadwork, landscaping, and site preparation. Vibratory compactors provide even compaction, reducing the risk of uneven surfaces.

Quick Couplers

Quick couplers allow you to switch between attachments quickly and safely. These devices save time on the job site by eliminating the need for manual pin changes. Hydraulic quick couplers are especially popular for their ease of use and reliability.

Tiltrotators

Tiltrotators add flexibility to your excavator by allowing attachments to rotate 360 degrees and tilt at various angles. This capability is invaluable for precision tasks like grading, trenching, and landscaping. Tiltrotators improve efficiency by reducing the need to reposition the machine.

Mulchers

Mulchers are designed for clearing vegetation, including trees, shrubs, and underbrush. These attachments are commonly used in forestry, land clearing, and landscaping projects. Mulchers shred vegetation into fine mulch, which can be left on-site as ground cover.

Shears

Shears are specialized attachments for cutting through metal, such as pipes, beams, and rebar. They are essential for demolition and recycling projects. Hydraulic shears provide powerful cutting force, making them ideal for heavy-duty applications.

Cold Planers

Cold planers are used for milling asphalt or concrete surfaces. These attachments are essential for road repair and resurfacing projects. They remove layers of material with precision, creating a smooth surface for new pavement.

Tip: Regular maintenance of mini excavator attachments, such as lubrication and hydraulic system checks, ensures optimal performance and extends their lifespan. Using high-quality materials and adhering to manufacturer-recommended schedules can significantly reduce repair costs over time.

Each of these types of excavator attachments serves a unique purpose, allowing you to customize your mini excavator for specific tasks. By understanding their capabilities, you can maximize efficiency and productivity on the job site.

Applications

Earthmoving

You use mini excavator attachments for earthmoving when you need to move large amounts of soil or debris. Buckets play a key role in this application. You can choose a standard bucket for general excavation or a grading bucket for leveling surfaces. These attachments help you dig, scoop, and transport soil efficiently. When you need to prepare a site for construction, you rely on your excavator and its bucket to handle the heavy lifting.

Trenching

Trenching is one of the most common applications for mini excavator attachments. Trenching buckets create narrow, precise trenches for utilities or irrigation. You achieve consistent widths and slopes, which saves you time and materials. For example, a trenching bucket can reduce excess soil removal by about 40%. Hydraulic augers and rippers also help you break up tough ground before digging. These types of attachments let you finish utility trenches in about one-third the time compared to standard buckets, with less landscape disruption.

Drilling

When you need to drill holes for fence posts, trees, or foundations, you attach an auger to your mini excavator. Augers provide steady torque and make digging holes in hard or rocky soil much easier. You select the right size auger for your project, and the excavator does the heavy work. This application saves you manual labor and increases precision.

Demolition

You use hydraulic breakers and shears for demolition of concrete structures and other tough materials. These attachments deliver powerful force to break apart concrete, asphalt, or metal. You can also use a bucket to remove debris after breaking. For smaller jobs, a ripper attachment helps you break up hard surfaces before digging.

Material Handling

Grapples and thumbs help you handle irregular materials like logs, rocks, or scrap. You use these attachments to grip, lift, and move objects safely. A bucket with a thumb attachment lets you pick up large debris during site cleanup. These applications keep your job site organized and efficient.

Forestry Work

Mulchers and grapples are essential for forestry applications. You use a mulcher to clear brush and trees, turning them into mulch. Grapples help you move logs and branches. Your excavator attachments make land clearing and site preparation much faster.

Landscaping

Landscaping applications require grading, digging, and moving materials. You use a grading bucket to level soil for lawns or gardens. A tiltrotator attachment helps you shape slopes and contours with precision. You can also use a compactor to firm up soil or gravel after excavation.

Note: Matching the right mini excavator attachments to each application improves your efficiency, reduces manual labor, and helps you achieve better results on every job.

Selecting Attachments

Project Requirements

When you select mini excavator attachments, start by looking at your project needs. Every job has unique requirements. You might need a bucket for digging or grading, or a grapple for handling debris. Many industries, such as construction, mining, agriculture, and forestry, use different types of attachments for specific applications. Manufacturers now design attachments to match customer needs, so you can find the right tool for your task. New technology, like sensors and machine control, helps you work with more precision and safety. Matching attachments to your project increases productivity and reduces mistakes.

Mini excavators work well in tight spaces, making them popular for urban projects.

Quick couplers and tiltrotators let you switch attachments fast, saving time.

Using the right attachment for each application can boost productivity by up to 40%.

Material and Terrain

Think about the material and terrain at your job site. Hard soil, rocky ground, or loose sand all need different attachments. For example, a ripper works best for breaking up tough ground before digging. A grading bucket helps you level soil for landscaping. If you work in forestry, a mulcher or grapple fits your needs. Always match the attachment to the ground and material for the best results.

Compatibility

Check that your attachments fit your excavator. Many brands make different sizes and hydraulic systems. Compatibility problems can slow you down and increase costs. Manufacturers now focus on making attachments that work with many excavator models. Quick couplers help you change attachments safely and quickly, but always confirm the fit before you start.

Cost Factors

Cost matters when you choose attachments. High prices can limit your options, especially if you need many types for different applications. Some companies use data and expert advice to study costs and forecast trends. You can save money by picking attachments that boost productivity and reduce fuel use. Machine control systems and the right attachments can cut labor costs and lower the cost per yard. Always balance price, efficiency, and the needs of your excavator.

Tip: Accurate matching of attachments to job conditions can improve productivity by up to 40%, reduce rework, and save on fuel and labor.

Maintenance and Safety

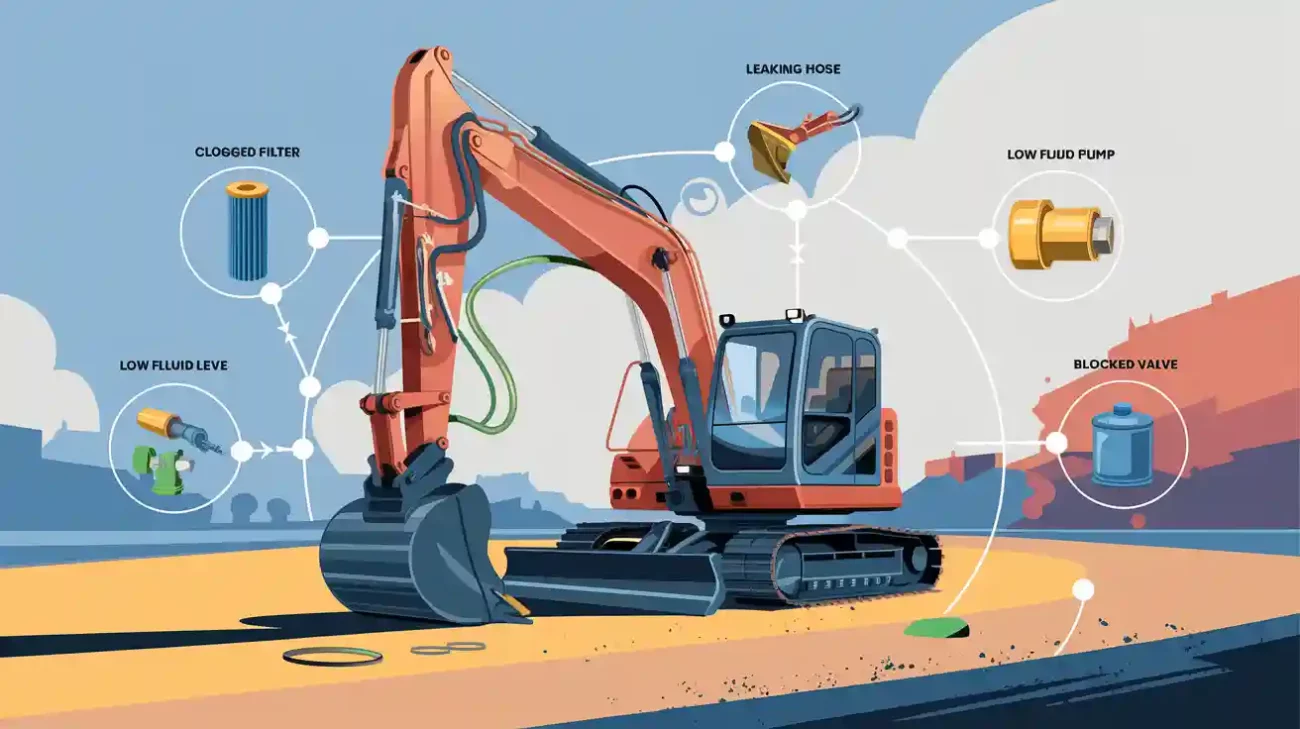

Inspection

You keep your mini excavator running smoothly when you inspect attachments regularly. Start each day by checking hydraulic fluid levels and looking for leaks around hoses and fittings. Examine the bucket, couplers, and other attachments for cracks or worn parts. Clean hydraulic hose ends to prevent dirt from entering the system. Follow a schedule for deeper checks: inspect retaining pins and tools weekly, check tool shanks and bushings monthly, and service hydraulic hoses every 50 hours. Annual inspections help you find hidden wear and replace worn components before they fail. When you follow these steps, you spot problems early and avoid costly repairs. Studies show that equipment with regular inspections lasts 30-40% longer and has up to 22% less unplanned downtime. You also lower your operating costs by up to 12%.

Safe Operation

You protect yourself and your team by using attachments safely. Always make sure locking mechanisms work before you start. Lubricate moving parts as the manufacturer recommends. Never use a bucket or other attachment for a job it was not designed to do. Train every operator to perform pre-operation checks and communicate clearly on the job site. Clean filters weekly and change oil monthly to keep the excavator in top shape. Schedule quarterly hydraulic system checks and annual full inspections. These habits reduce the risk of hydraulic leaks, unexpected movements, and breakdowns. When you follow best practices, you prevent accidents and keep your excavator and attachments working longer.

Tip: A well-maintained excavator with properly cared-for attachments gives you better performance, fewer breakdowns, and a safer work environment.

Understanding the types and uses of each excavator attachment helps you work smarter and safer. When you match the right excavator tool to your project, you boost efficiency and reduce risks. The table below shows how proper excavator attachment selection improves safety and productivity:

Key Aspect | Example | Impact on Safety and Efficiency |

|---|---|---|

Tilt rotators, quick couplers | Fewer equipment changes, safer job sites | |

Automated attachments, sensors | Less human error, better control | |

Custom excavator fit | Adapters, tailored attachments | Prevents delays, maximizes operational benefits |

You should always check that your excavator attachments fit your machine and job needs. Ask an expert or dealer for advice if you are unsure. Regular maintenance keeps your excavator and attachments working at their best.